Anti-floating glass toughening manure pit

A technology of glass tempering and septic tanks, which is applied in the direction of biological sludge treatment, etc., can solve the problems of long construction period, septic tank leakage, pollution of groundwater sources, etc., and achieve the effect of simple structure and elimination of buoyancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

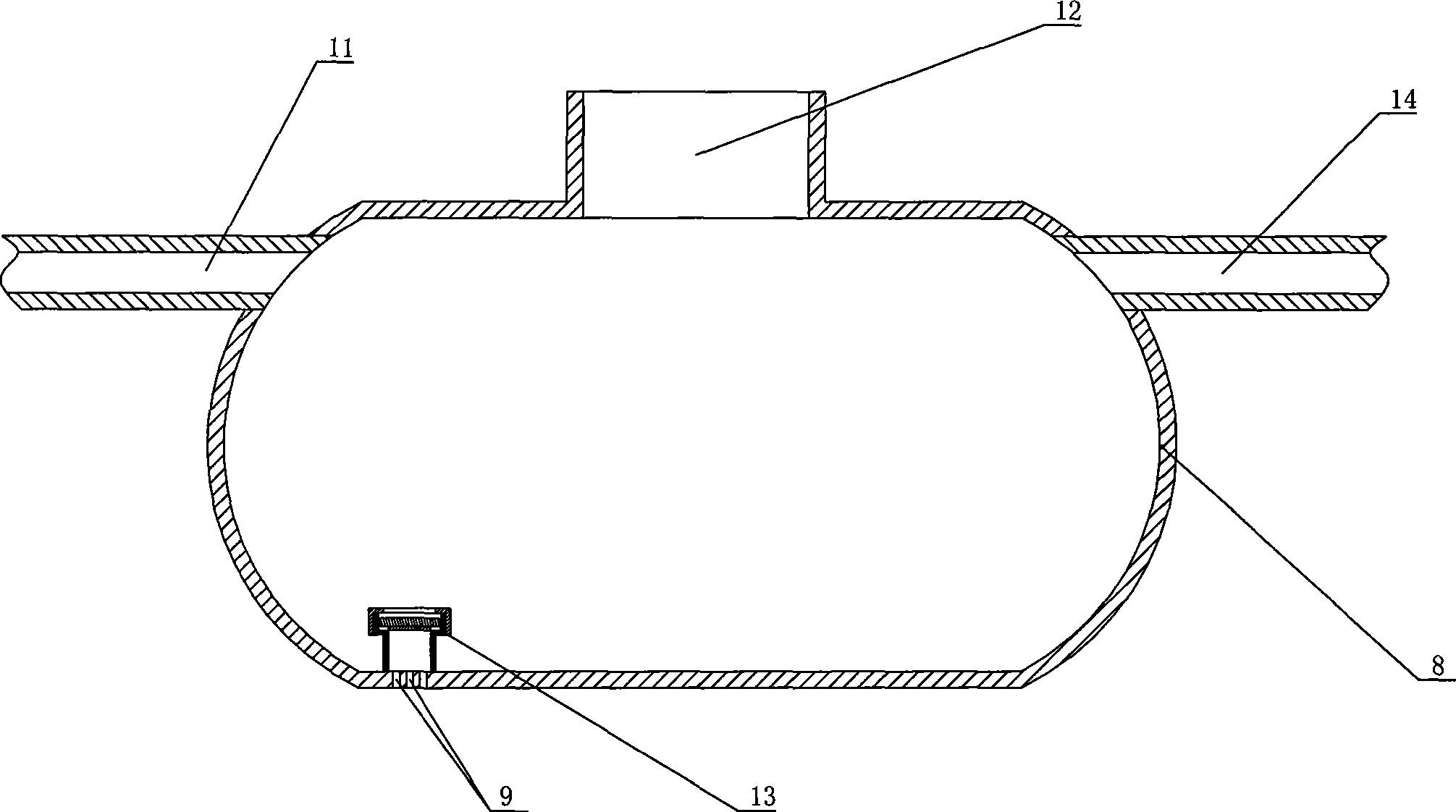

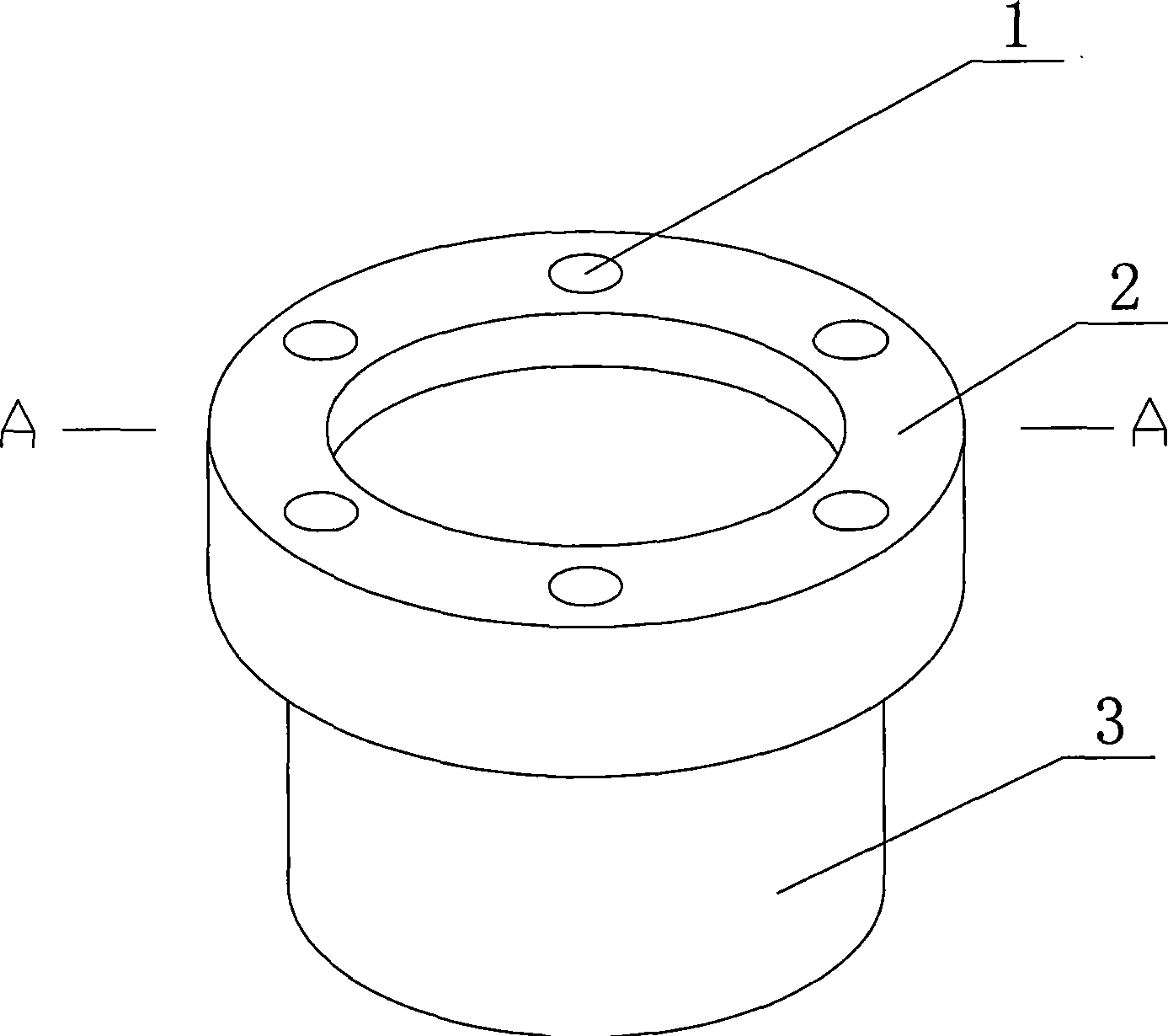

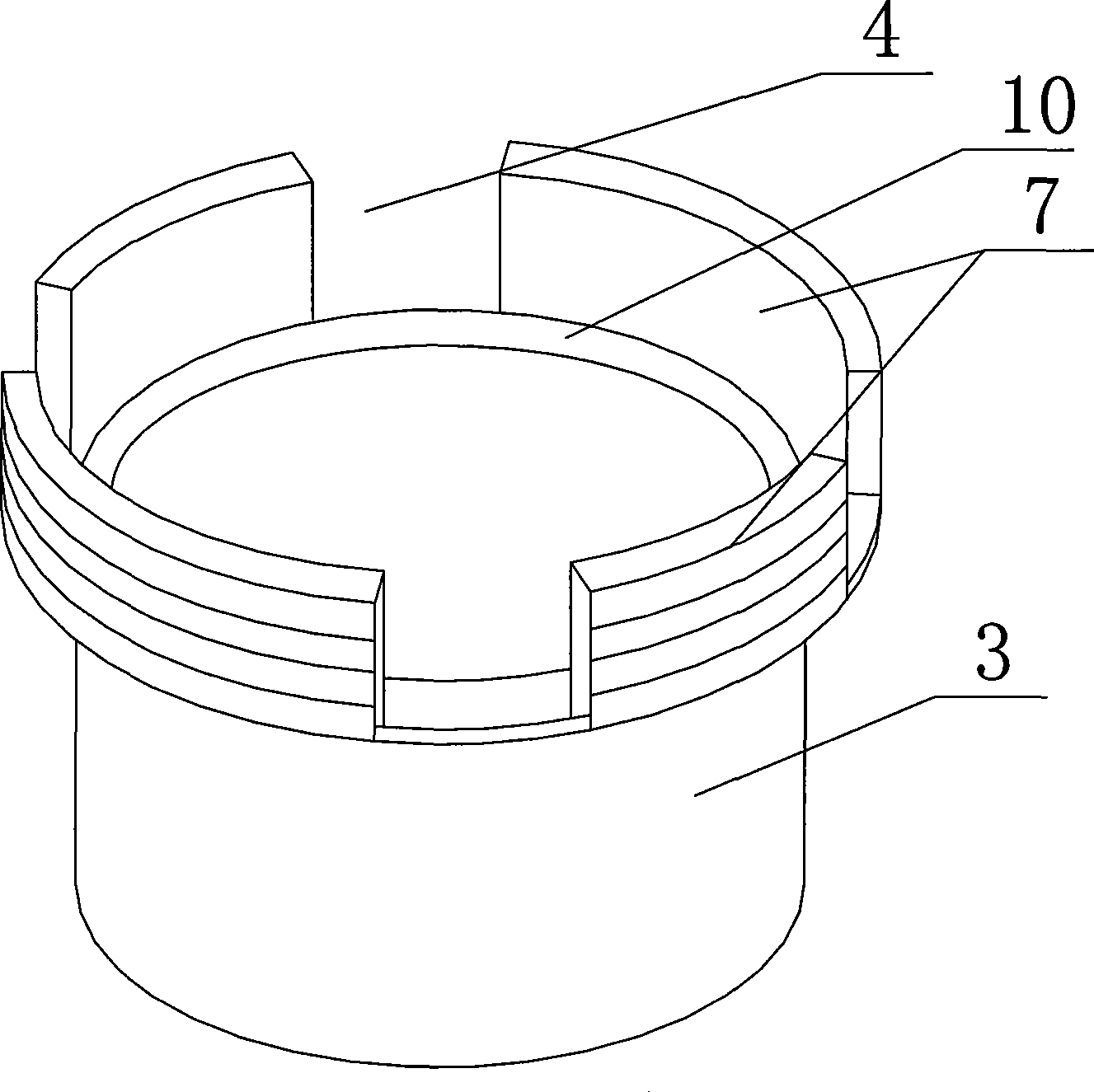

[0017] The specific implementation of the anti-floating FRP septic tank will be described in detail below in conjunction with the accompanying drawings.

[0018] Such as figure 1 , 2 , Shown in 3 and 4, a kind of anti-floating FRP septic tank comprises a pool body 8, on which a water inlet 14, a water outlet 11 and a dirt cleaning port 12 are arranged, in the pool body 8 The bottom is sealed and fixed with a diversion valve 13. The diversion valve 13 includes a valve body 3 and a water-permeable regulating cover 2. One end of the valve body 3 is provided with a screw port 7, and the other end is sealed and fixed on the pool body 8. On the fixed end, the screw port 7 is screwed with a water-permeable regulating cover 2, and there is a step 10 between the screw port 7 and the fixed end of the valve body 3, and a seal is arranged on the step 10 in turn. The ring 6 and the isolation plate 5 are provided with a through hole 9 communicating with the outside in the area determined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com