A hollow slab filled with a breathable box

A technology of hollow floor and ventilating box, which is applied in the direction of floors, building components, buildings, etc. It can solve the problems of filling materials such as troublesome binding of steel bars, small filling material stiffness, and large buoyancy of filling materials, so as to overcome construction difficulties and achieve heat insulation effect Good, large-span effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

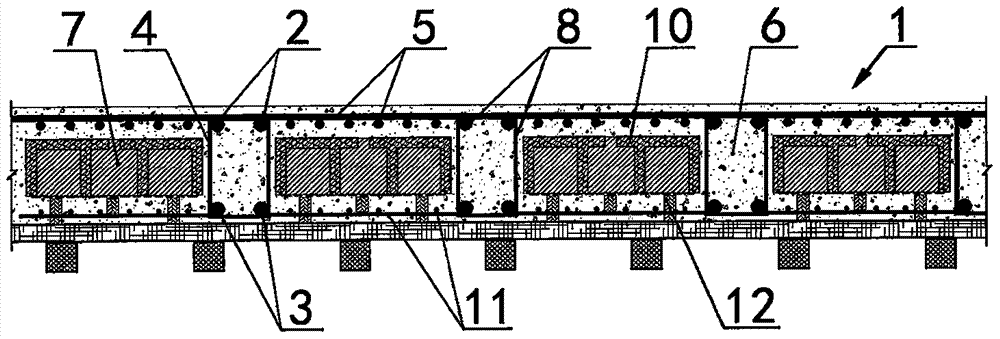

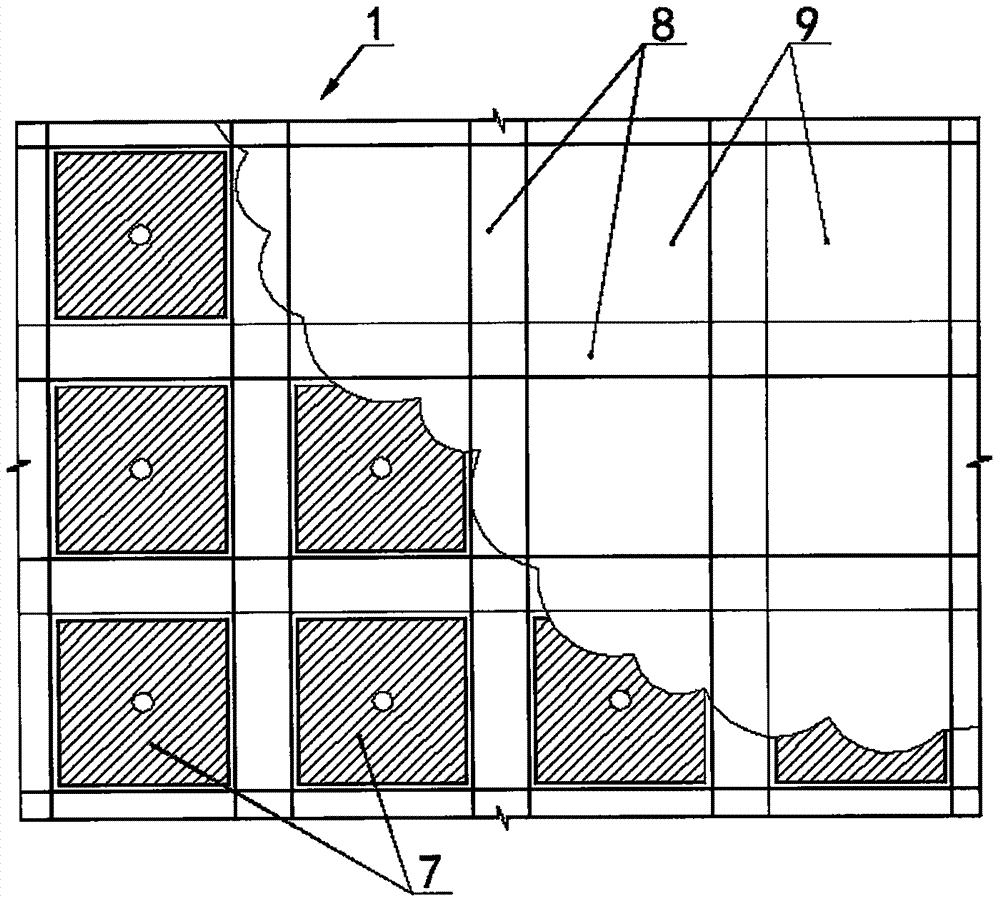

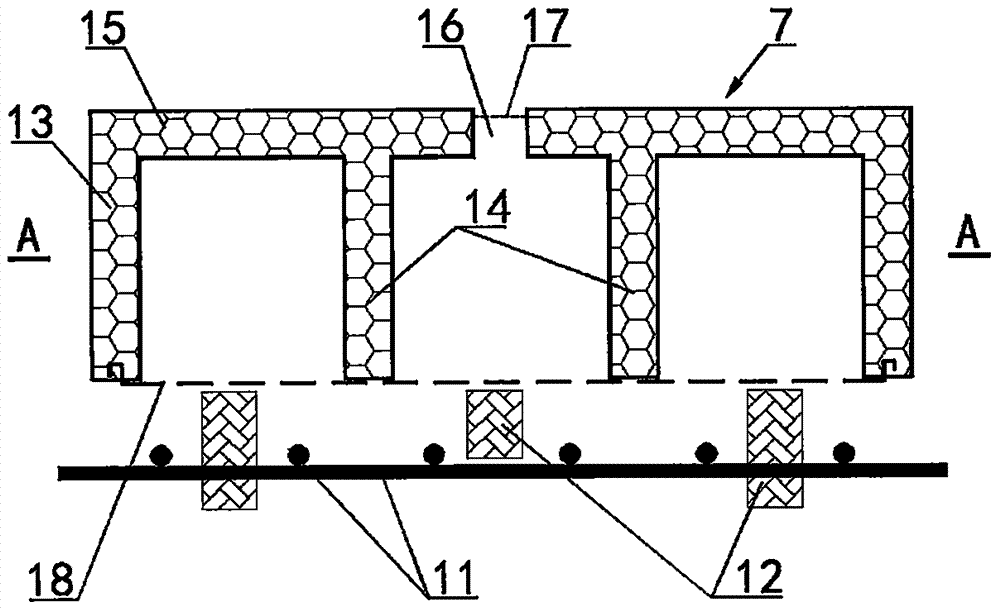

[0031] The present invention is realized in the following manner:

[0032] exist Figure 1-Figure 3 , Figure 8 In the shown embodiment, a hollow slab filled with air-permeable boxes, the hollow slab (1) includes beam upper iron (2), beam lower iron (3), rib beam stirrups (4), plate iron (5), concrete (6) and breathable box combination (7), beam upper iron, beam lower iron and rib beam stirrups constitute rib beam (8), and the rib beam with two directions orthogonal to each other connects the hollow floor The plane is divided into a plurality of compartments (9), and the vent box (10) forms a vent box assembly (7) together with the steel wire mesh (11) and the positioning spacer (12), and the vent box assembly is installed in each compartment, Bind plate iron on the upper part of the ventilation box assembly, and form a hollow floor after pouring concrete, and the thickness of the concrete at the lower part of the ventilation box is ≥ 30mm.

[0033] exist Figure 1-Figure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com