Anti-floating method for thin-walled square box in flat slab floor

A beamless floor and square box technology, which is applied to floors, building components, buildings, etc., can solve the problems of overall floating, square boxes are easy to float and shift, and the anti-buoyancy force is not in the same vertical direction. Floating, good anti-floating effect, reducing the effect of cumbersome construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

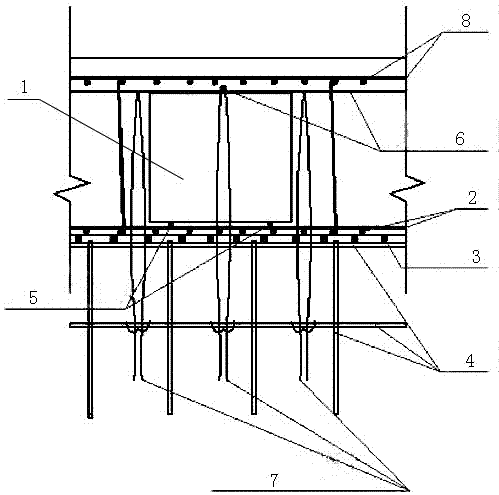

[0021] Such as figure 1 Shown: a thin-walled square box anti-floating method in a beamless floor, which includes the following steps:

[0022] Step 1: Construction preparation;

[0023] Check the appearance of the other box 1 one by one, and repair the damaged ones, and the height meets the deviation requirements, and the deviation is within ±10mm;

[0024] Step 2: Square box installation;

[0025] Install the bottom plate ribs 2 on the bottom plate formwork 3, and the lower part of the bottom plate formwork is provided with a supporting steel pipe frame 4, then transfer the square boxes to the bottom plate ribs with a hanging basket, and stack them in a scattered manner to avoid large concentrated loads, and play the grid well line, place pads 5 on the bottom plate reinforcement, and lift the square box on the pads, each square box corresponds to four pads, adjust the alignment to ensure that the square boxes and the square box and hidden beams, walls, The spacing between ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com