Excavating construction method for surge shaft in gravel and sandy soil layer

A technology of gravel sand layer and construction method, which is applied in the field of surge well engineering, achieves the effects of high cost, difficult slag removal, and accelerated construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Attached below Figure 1~4 And embodiment the present invention is described further.

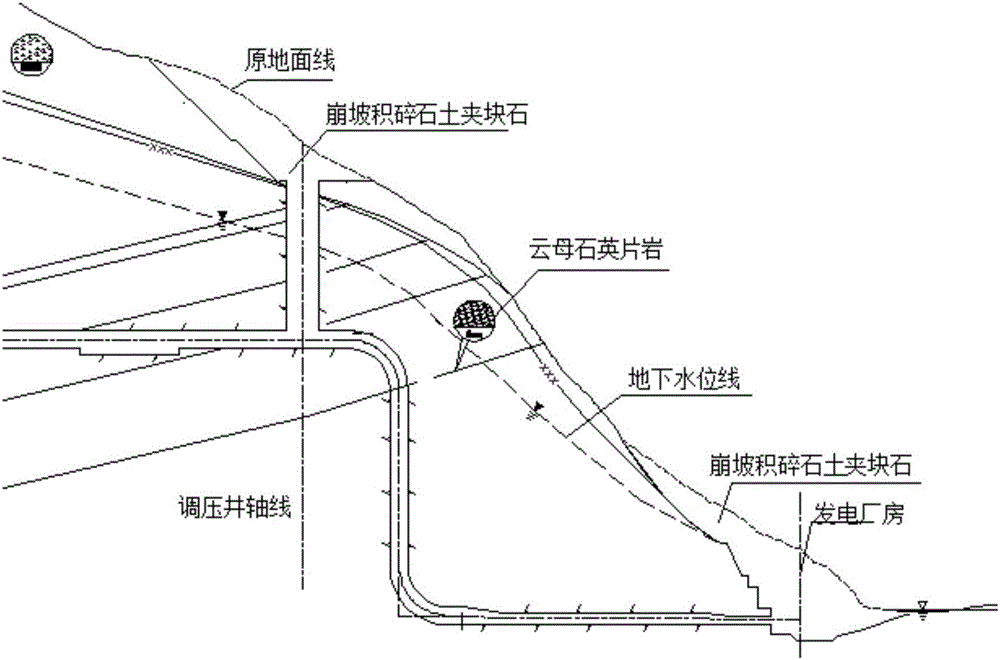

[0055] In this embodiment, the method of the present invention is applied to the construction project of Shangmaxiangdi A Hydropower Station.

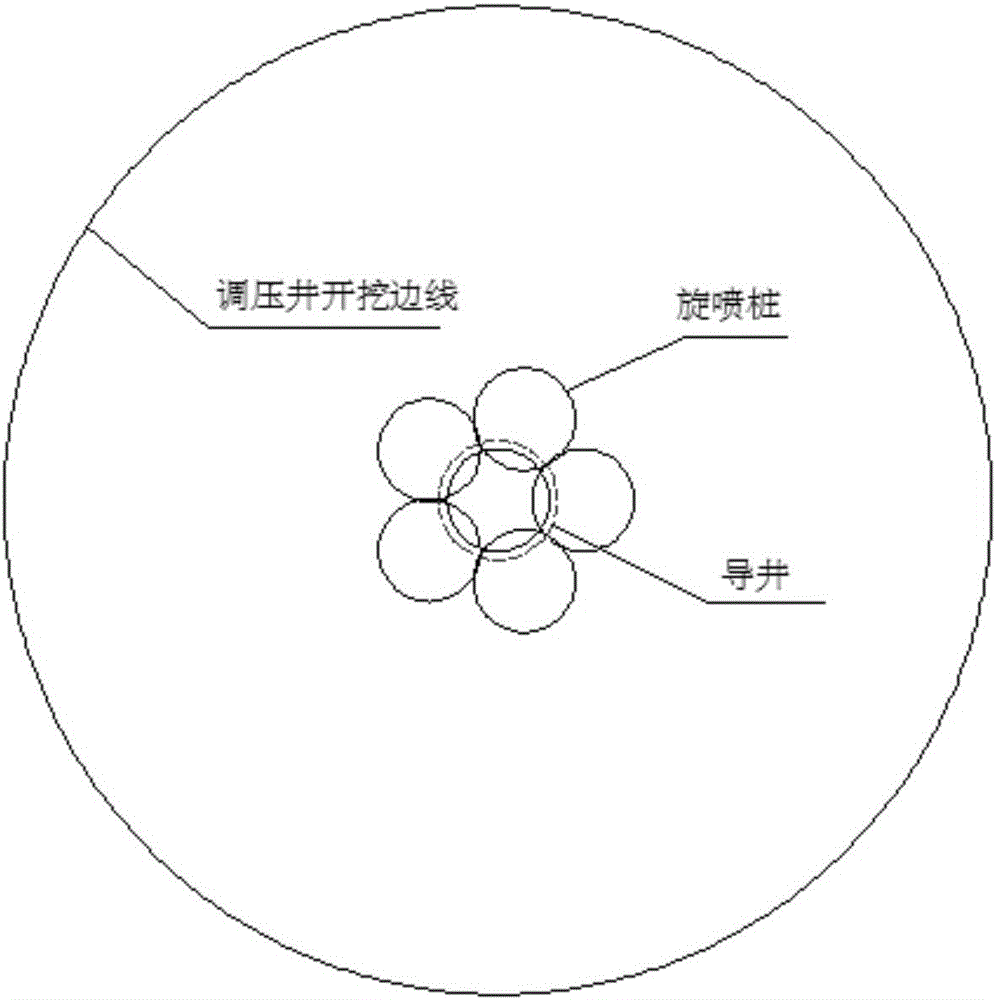

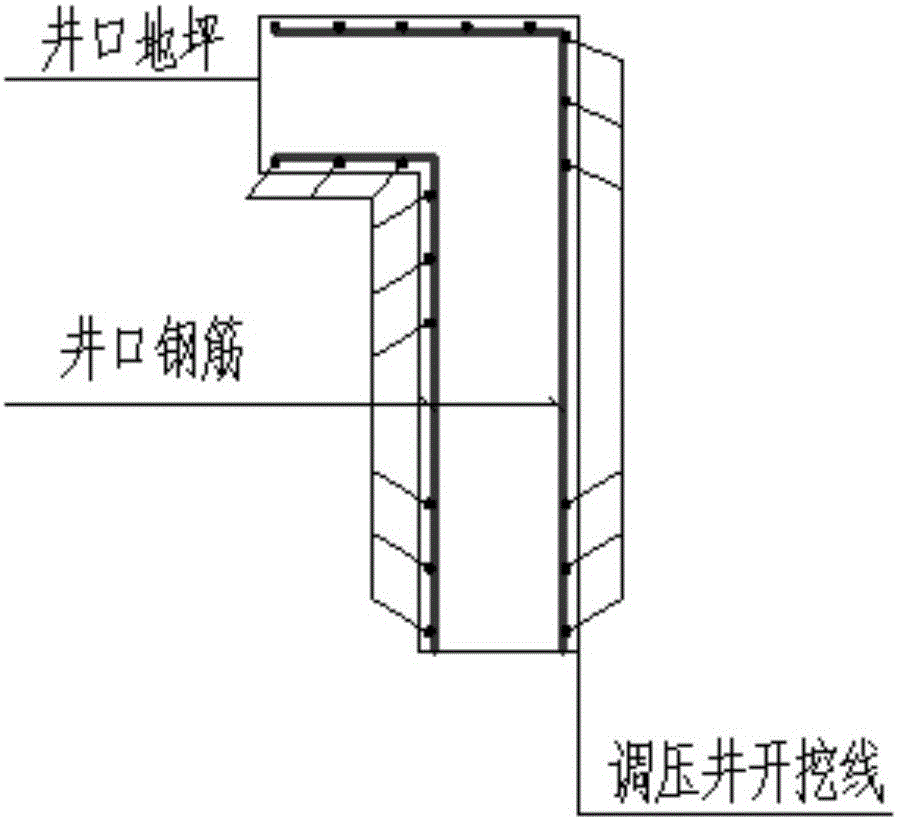

[0056] The surge shaft of Shangmaxiangdi A hydropower station is arranged at the end of the water diversion system on the left bank of the Maxiangdi River. A circular section impedance surge shaft with a diameter of 11.6m was excavated. After lining, the diameter of the impedance hole is 3.2m, and the diameter of the large well is 10m. The excavation height of the side slope of the surge shaft is about 50m, the elevation of the top of the well is EL938.10m, the elevation of the bottom of the impedance well is EL876.10m, and the height difference is 62m.

[0057] The surface of the surge shaft is covered by collapsing gravel soil interbedded with rocks, 15-25m thick; the bedrock below it is mica schist and mica-quartz schist, and the bottom i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com