Method for performing extraction treatment on corner gas on work faces of adjacent roadways

A technology for working face and coal mining face, which is applied in the directions of gas discharge, earth-moving drilling, safety devices, etc., can solve the problems of heavy excavation workload, high cost, damage to the drainage pipeline, etc., and achieve the effect of improving the construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

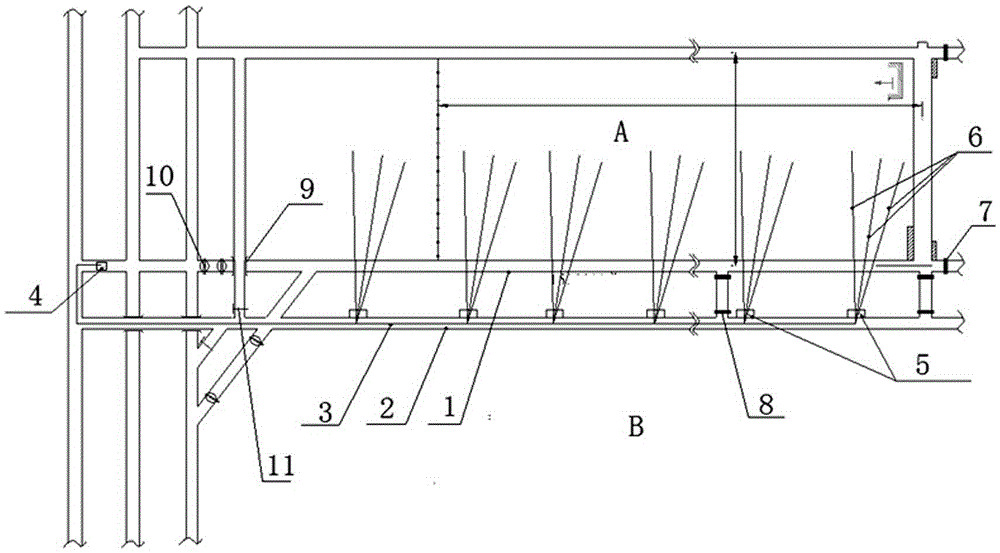

[0008] Such as figure 1 As shown in the illustration, a method of draining adjacent roadways to control the corner gas on the working face, after the return air channel 1 of the coal mining face A is completed, the return air lane 2 of the next working face B is arranged in advance at an interval of 30 meters. Arrange the gas drainage pipeline 3 in the return airway 2, and arrange a gas drainage drilling site 5 at an interval of about 80 meters in the return airway 2, and construct a drilling hole 6 in the gas drainage drilling site 5 for drainage For gas in the upper corner of the coal mining face A, after the coal mining face A is drained, a borehole facing the coal mining face B is drilled in the drilling site to drain the gas.

[0009] An airtight wall 8 is provided between the return air channel 1 and the return air channel 2, and a wind bridge 9 is erected between the roadway of the coal mining face A and the return air channel 1, and a wind bridge 9 is installed at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com