Construction method for straight manhole

A construction method and straight-through technology, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve problems such as high construction costs, multiple brick joints, and excessively long periods, shortening the construction period, reducing workload, Strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

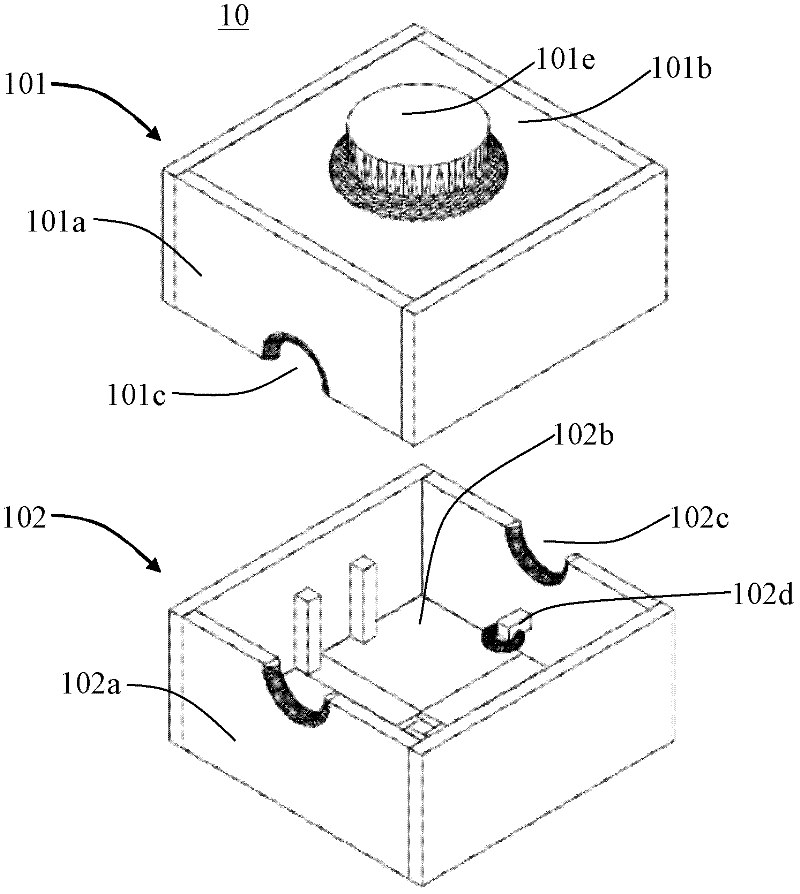

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] The present invention provides a new straight-through type manhole construction method, and the new manhole construction method includes the following steps:

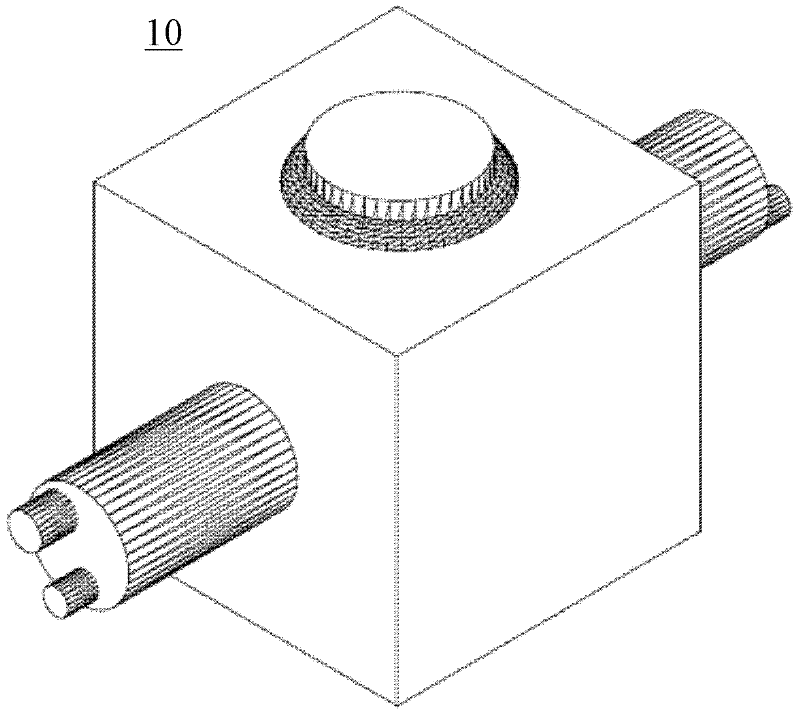

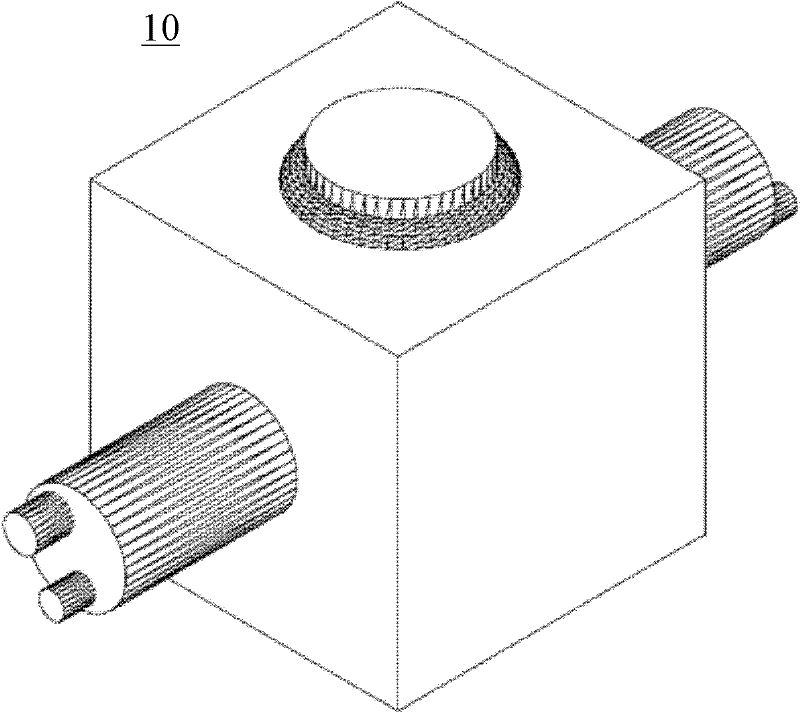

[0025] 1. The prefabricated man well is prefabricated with concrete as a whole, and is approximately rectangular in shape;

[0026] 2. The four corners of the side where the top cover needs to be installed are reinforced with steel bars; the foundation pit enclosure and foundation pit excavation are done according to the size of the manhole to form the manhole foundation pit;

[0027] 3. After the manhole foundation pit is completed, the concrete foundation is poured;

[0028] 4. Paint the anti-seepage treatment paint on the concrete surface on the soil-facing surface of the prefabricated manhole, and paste the water-swellable rubber waterstop. The so-called soil-facing surface refers to the outer surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com