Machine for casting curbs in situ and use method thereof

A technology of curbs and implements, applied in roads, roads, road repair and other directions, can solve the problems of cumbersome and labor-intensive, and achieve the effect of eliminating the process of alignment adjustment, speeding up the construction progress, and saving labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

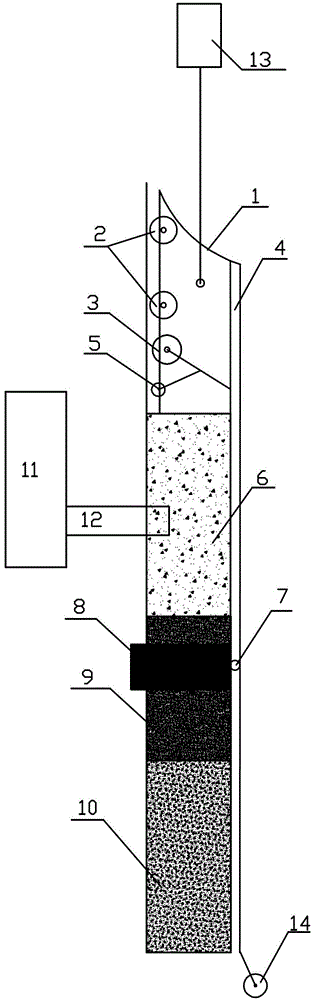

[0017] With reference to the accompanying drawings, a machine tool for cast-in-place concrete curbs includes a machine body and a traction device 13 located in front of the machine. The traction device is preferably a hoist, and the hoist can be driven by a small tractor. The above-mentioned tool body includes a plow-shaped shovel 1 positioned at the front end, and its width is slightly narrower than that of the curb, such as 2-3 cm smaller than the width of the curb. A number of guide wheels 2 equal to or more than two are arranged on the inner side of the front end of the implement, and a bottom steel plate for smoothing the bottom of the curb groove is arranged at the bottom of the front end of the implement body, and the bottom steel plate is connected with the bottom edge of the plow-shaped shovel and the bottom edge of the outer formwork of the implement. Welded through length. On the rear side of the guide wheel, there is a film-coated roller 3 that is 5 to 10 cm highe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com