Anti-blocking and anti-floating grouting material for shield tunnel synchronous grouting

A technology of synchronous grouting and shield tunneling, applied in the field of grouting materials, can solve the problems of restricting the application of cement-sodium silicate double slurry, the floating of the shield lining structure, and insufficient strength of the stone body, etc., so as to delay the physical gelation time , continuous grouting, prolonging the effect of chemical gelation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

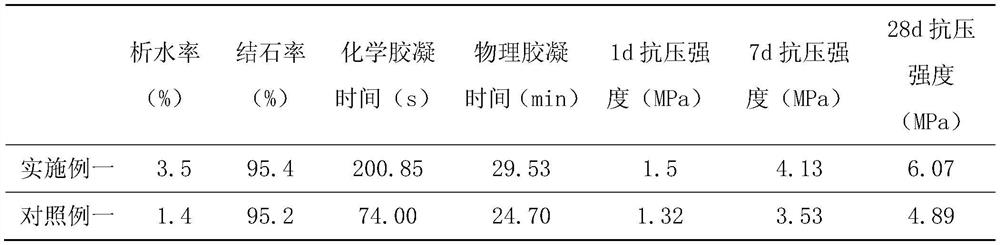

Embodiment 1

[0016] A specific embodiment of the present invention is a grouting material for synchronous grouting of shield tunnels with anti-blocking and anti-floating, the components of which are water, cement, water glass and retarder, characterized in that: the cement It is 42.5-grade Portland cement; the water glass is an aqueous sodium silicate solution with a Baume degree of 30° and a modulus of 3.1, and the retarder is a diphosphate diphosphate with a purity of 99.0%, a pH value of 4.0, and a clarity of 3.0. ammonium hydrogen crystals.

[0017] The mass ratio of each component of this example is: 675 parts of water, 281 parts of cement, 319 parts of water glass, and the quality of retarder is 0.75% of cement quality.

[0018] In order to verify the performance of the grout added with a trace amount of ammonium dihydrogen phosphate in the present invention, a grout without added trace amount of ammonium dihydrogen phosphate was prepared as a control, and performance tests were perf...

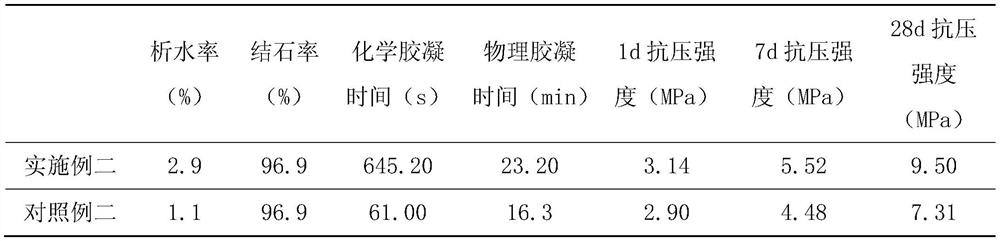

Embodiment 2

[0031] The anti-blocking and anti-floating shield tunnel synchronous grouting grouting material of this example is composed of water, cement, water glass and retarder, and is characterized in that: the cement is 42.5 grade Portland cement; The glass is an aqueous solution of sodium silicate with a Baume degree of 40° and a modulus of 3.3, and the retarder is ammonium dihydrogen phosphate crystals with a purity of 99.5%, a pH value of 4.5, and a clarity of 2.0.

[0032] The mass ratio of each component of this example is: 659 parts of water, 330 parts of cement, 319 parts of water glass, and the quality of retarder is 1% of cement quality.

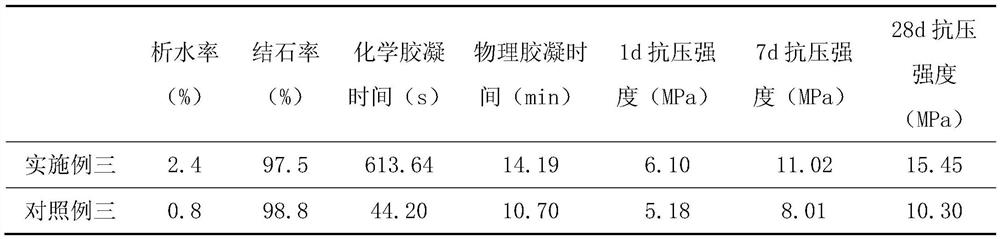

Embodiment 3

[0041] The anti-blocking and anti-floating shield tunnel synchronous grouting grouting material of this example, its component is water, cement, water glass and retarder, it is characterized in that: described cement is 42.5 grade Portland cement; The glass is an aqueous solution of sodium silicate with a Baume degree of 35° and a modulus of 3.2, and the retarder is ammonium dihydrogen phosphate crystals with a purity of 99.9%, a pH value of 4.2, and a clarity of 2.5.

[0042] The mass ratio of each component of this example is: 636 parts of water, 397 parts of cement, 319 parts of water glass, and the quality of retarder is 0.98% of cement quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com