Graphene-loaded nano zero-valent copper/iron bimetallic composite material based on nano primary battery effect and preparation method and application thereof

A nano-zero-valent iron and nano-zero-valent technology, applied in the field of water treatment, can solve the problems of poor removal stability and easy desorption of heavy metals, and achieve the effects of improving reduction and removal efficiency, increasing electromotive force, and improving oxidation resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of Cu / Fe / rGO composite material, comprising the following steps:

[0029] Step 1. Ultrasonically disperse 1.0g of graphene oxide into 100mL of water, add 7.58g of ferrous sulfate solution and 25mL of hydrazine hydrate under the condition of stirring at 500rpm, and put it in an autoclave for a reduction reaction at 120°C for 24h;

[0030] Step 2, the cooled product is filtered and washed, and vacuum-dried at 60° C. to obtain the Fe / rGO nanocomposite;

[0031] Step 3. Redisperse Fe / rGO into 100mL of water, add 7.98g of copper sulfate, and put it in an autoclave at 120°C for 24 hours of displacement reaction;

[0032] Step 4: Suction filter and wash the cooled product, and vacuum-dry at 60° C. to obtain a Cu / Fe / rGO composite material.

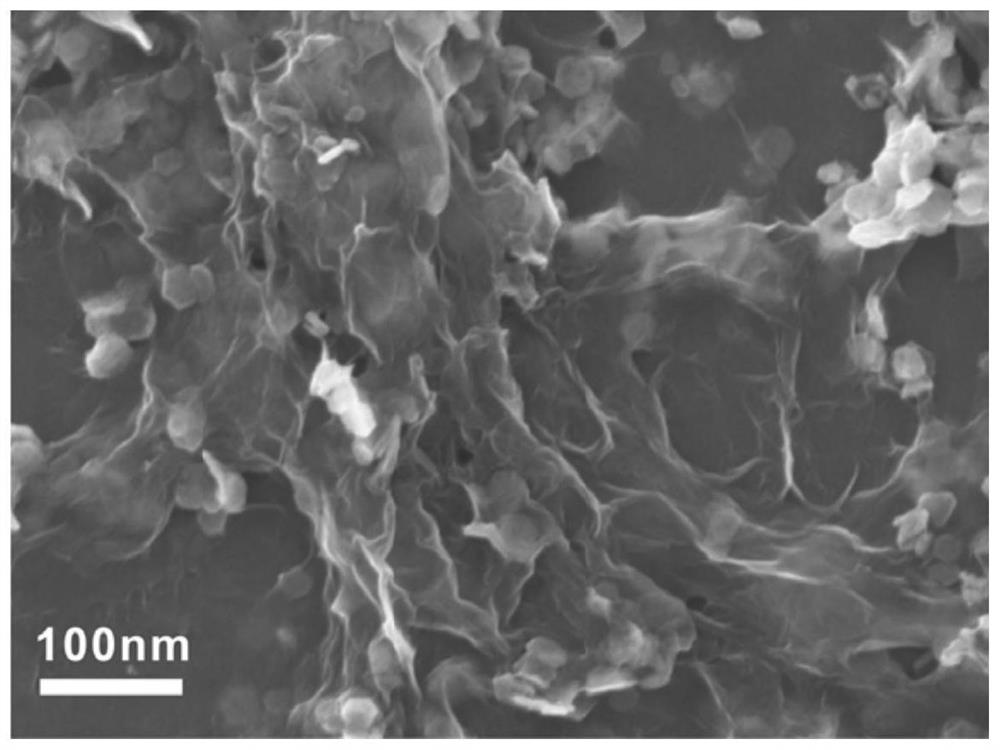

[0033] The morphology of the Cu / Fe / rGO composite synthesized in Example 1 was characterized by scanning electron microscopy, as shown in Figure 1, it can be seen that nano-sized zero-valent copper-iron bimetals were su...

Embodiment 2

[0035] A method for preparing a Cu / Fe / rGO composite material, comprising the following steps:

[0036] Step 1. Ultrasonic disperse 1.0g of graphene oxide into 100mL of water, add 9.00g of ferrous nitrate solution and 25mL of hydrazine hydrate under the condition of stirring at 500rpm, and put it in an autoclave for a reduction reaction at 120°C for 24h;

[0037] Step 2, the cooled product is filtered and washed, and vacuum-dried at 60° C. to obtain the Fe / rGO nanocomposite;

[0038] Step 3. Redisperse Fe / rGO into 100mL of water, add 9.38g of copper nitrate, and put it into an autoclave at 120°C for 24 hours of displacement reaction;

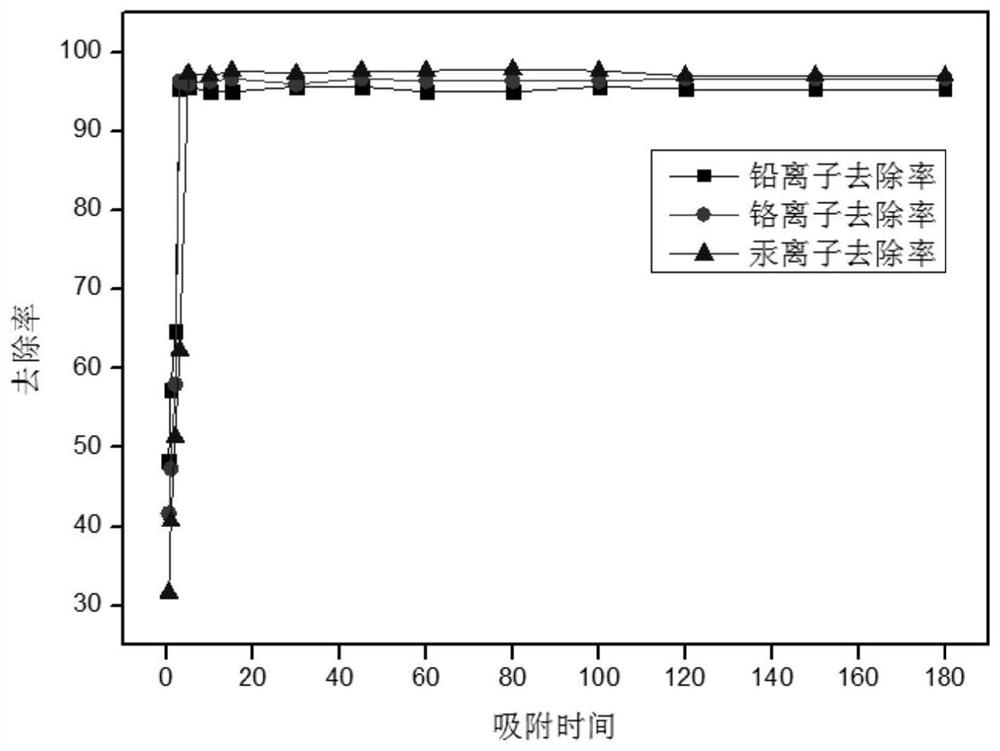

[0039] For the Cu / Fe / rGO composite material synthesized in Example 2, the test results show that the Cu / Fe / rGO composite material can remove the highly toxic heavy metal ions (lead, lead, Cadmium and mercury) are reduced to a low-toxic or non-toxic single substance state and deposited on the surface of the positive electrode material, and the re...

Embodiment 3

[0041] A method for preparing a Cu / Fe / rGO composite material, comprising the following steps:

[0042]Step 1. Ultrasonically disperse 1.0g of graphene oxide into 100mL of water, add 6.34g of ferrous chloride solution and 25mL of hydrazine hydrate under the condition of stirring at 500rpm, and put it in an autoclave for a reduction reaction at 120°C for 24h;

[0043] Step 2, the cooled product is filtered and washed, and vacuum-dried at 60° C. to obtain the Fe / rGO nanocomposite;

[0044] Step 3. Redisperse Fe / rGO into 100mL of water, add 6.72g of copper chloride, and put it in an autoclave at 120°C for 24 hours of displacement reaction;

[0045] For the Cu / Fe / rGO composite material synthesized in Example 3, the test results show that the Cu / Fe / rGO composite material can remove the highly toxic heavy metal ions (lead, lead, Cadmium and mercury) are reduced to a low-toxic or non-toxic single substance state and deposited on the surface of the positive electrode material, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com