Ferrous phosphate doping lithium anode material and preparation process

A technology of lithium ferrous phosphate and cathode material, applied in electrode manufacturing, phosphorus compounds, battery electrodes, etc., can solve the problems of poor cycle performance and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

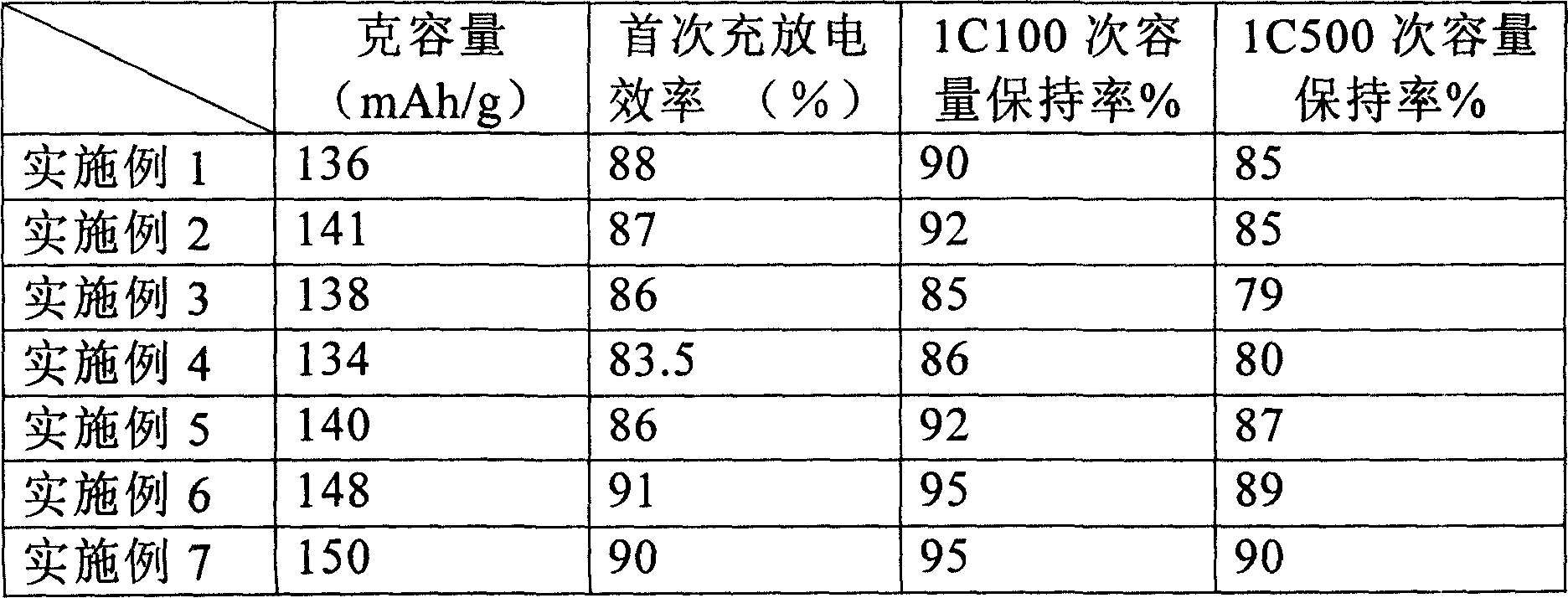

Examples

Embodiment 1

[0006] 1. Lithium carbonate, ferrous salt, chromium salt, zinc salt, calcium salt, phosphorus source and glucose material are 1.02: 0.99: 0.005: 0.0025 according to the atomic ratio with Li: Fe: Cr: Zn: Ca: P: C : 0.0025: 1: 0.05 mixed for 2 hours and then ball milled for 4 hours, the ball milling speed was 100 rpm.

[0007] 2. Preheating the powder material obtained in the above process at a low temperature of 350° C. for 5 hours under the protection of an inert atmosphere.

[0008] 3. After the above-mentioned preheated material is subjected to high-speed ball milling for 2 hours, the ball milling speed is 100 rpm, and under the protection of an inert atmosphere, it is burned for 8 hours at a high temperature of 600 ° C, cooled and ball-milled through a 300-mesh sieve to produce The present invention relates to a lithium iron phosphate cathode material whose interior is doped and the surface is coated with carbon elements with good electrical conductivity.

Embodiment 2

[0010] 1. Lithium carbonate, ferrous salt, chromium salt, zinc salt, calcium salt, phosphorus source and glucose material are 1.04: 0.99: 0.005: 0.0025 by the atomic ratio with Li: Fe: Cr: Zn: Ca: P: C : 0.0025: 1: 0.05 mixed for 2 hours and then ball milled for 4 hours, the ball milling speed was 100 rpm.

[0011] 2. Preheating the powder material obtained in the above process at a low temperature of 350° C. for 5 hours under the protection of an inert atmosphere.

[0012] 3. After the above-mentioned preheated material is subjected to high-speed ball milling for 2 hours, the ball milling speed is 100 rpm, and under the protection of an inert atmosphere, it is burned for 8 hours at a high temperature of 600 ° C, cooled and ball-milled through a 300-mesh sieve to produce The present invention relates to a lithium iron phosphate cathode material whose interior is doped and the surface is coated with carbon elements with good electrical conductivity.

Embodiment 3

[0014] 1. Lithium carbonate, ferrous salt, chromium salt, zinc salt, calcium salt, phosphorus source and glucose material are 1.06: 0.99: 0.005: 0.0025 by the atomic ratio with Li: Fe: Cr: Zn: Ca: P: C : 1: 0.0025: 0.05 mixed for 2 hours and then ball milled for 4 hours, the ball milling speed was 100 rpm.

[0015] 2. Preheating the powder material obtained in the above process at a low temperature of 350° C. for 5 hours under the protection of an inert atmosphere.

[0016] 3. After the above-mentioned preheated material is subjected to high-speed ball milling for 2 hours, the ball milling speed is 100 rpm, and under the protection of an inert atmosphere, it is burned for 8 hours at a high temperature of 600 ° C, cooled and ball-milled through a 300-mesh sieve to produce The present invention relates to a lithium iron phosphate cathode material whose interior is doped and the surface is coated with carbon elements with good electrical conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com