A lining trolley suitable for the construction of main tunnels and branch tunnels in parallel tunnels

A technology for lining trolleys and main tunnels, which is applied to tunnel lining, tunnel lining, shaft lining, etc. It can solve the problems of investment in construction and maintenance costs, increase in equipment costs, and consume a lot of manpower and material resources, so as to reduce labor costs and equipment costs. , reduce the number of trolleys, and simplify the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

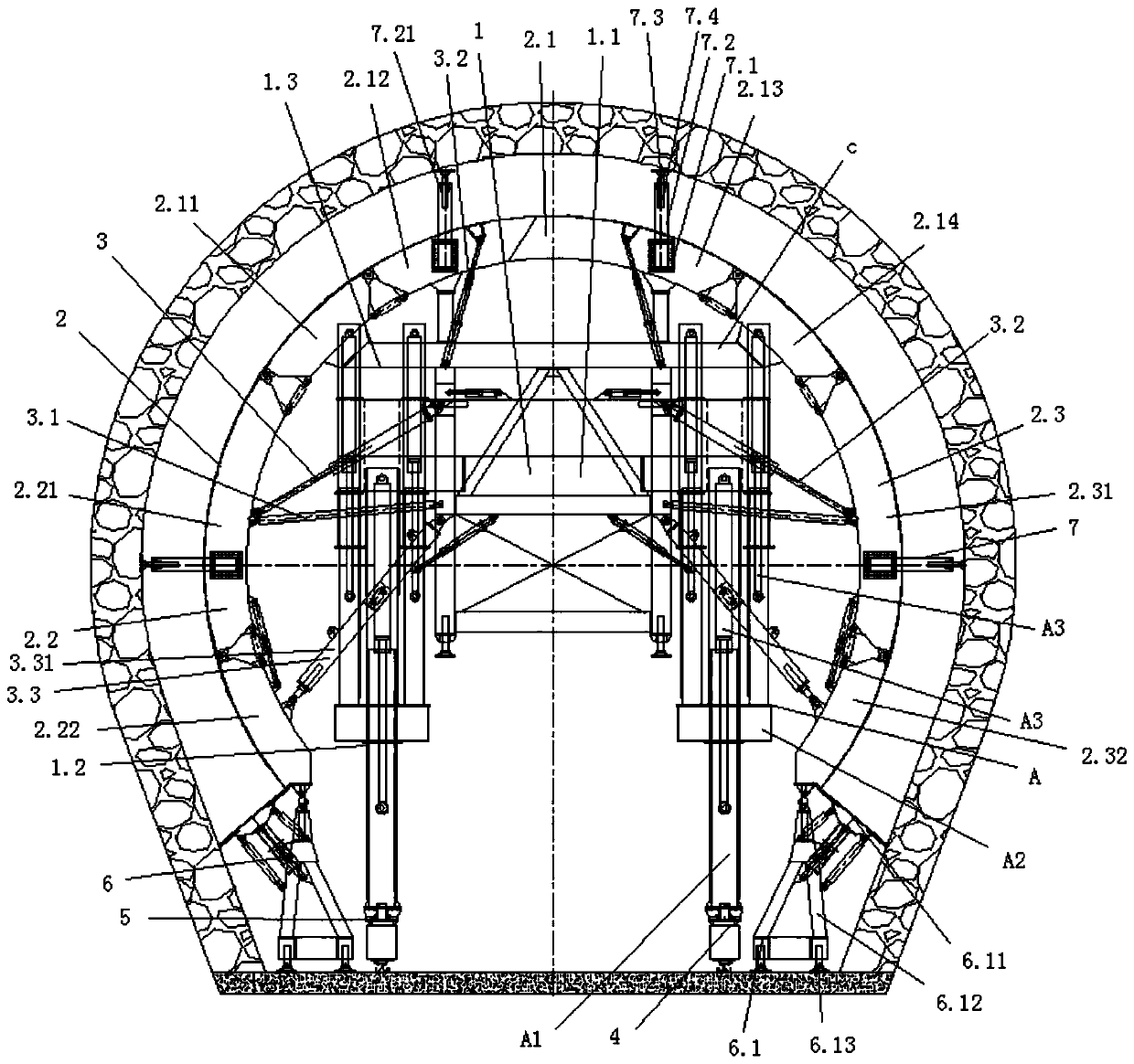

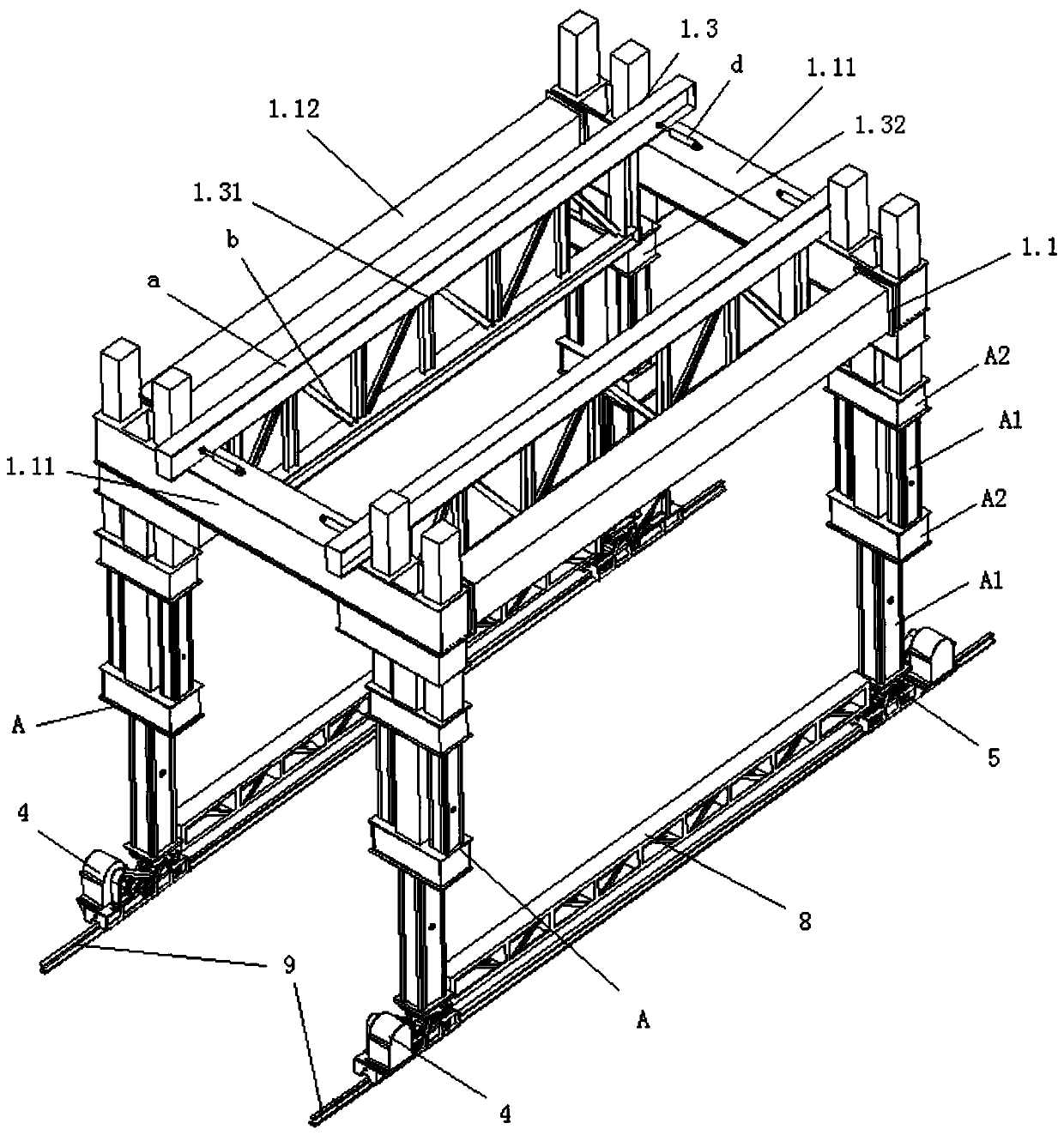

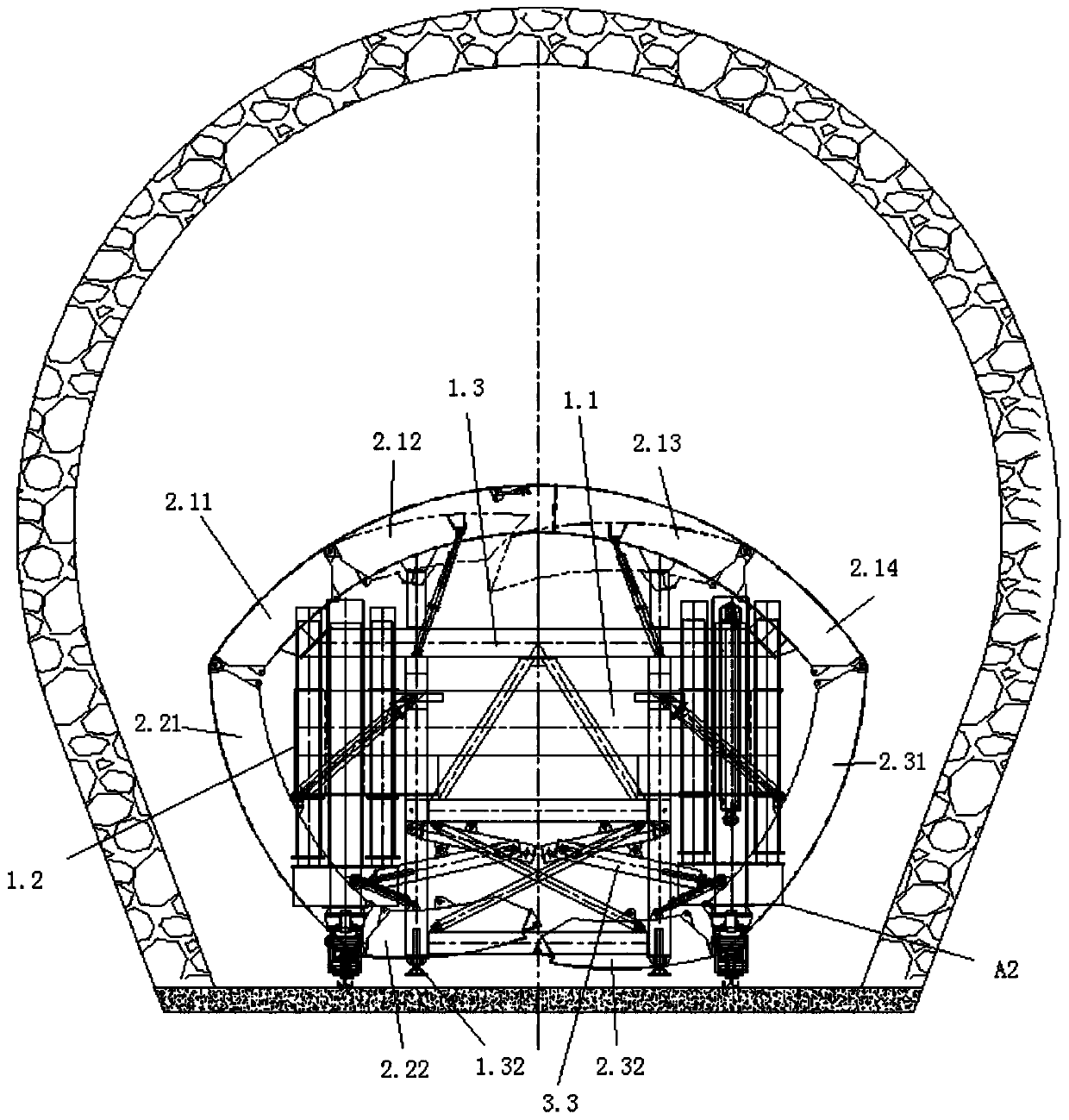

[0051] see Figure 1-Figure 5 , a variable cross-section tunnel lining trolley, including a portal frame system 1, a formwork system 2, a connecting part 3 connecting the portal frame system 1 and the template system 2, a walking mechanism 4 that drives the entire trolley to travel, and controls the entire platform. The control system for the movement of the trolley.

[0052] The gantry system 1 includes a frame part 1.1 and a jacking mechanism 1.2 and a bracket part 1.3 which are simultaneously arranged on the frame part 1.1, and the detailed structure is as follows:

[0053] The framework section 1.1 (see figure 1 with figure 2 ) is a mouth-shaped structure consisting of two mast beams 1.11 and two mast longitudinal beams 1.12.

[0054] The jacking mechanism 1.2 (see figure 1 with figure 2 ) includes four sets of jacking single pieces A arranged at the four corners of the frame part 1.1, and the lower ends of the guide columns A1 in the first-stage jacking parts of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com