Ditch sludge cleaning device

A technology for cleaning device and silt, which is applied in the direction of earth mover/shovel, construction, etc., can solve the problems of uneven silt cleaning surface at the bottom of the canal, easy accumulation of raised silt parts again, uneven human control force, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

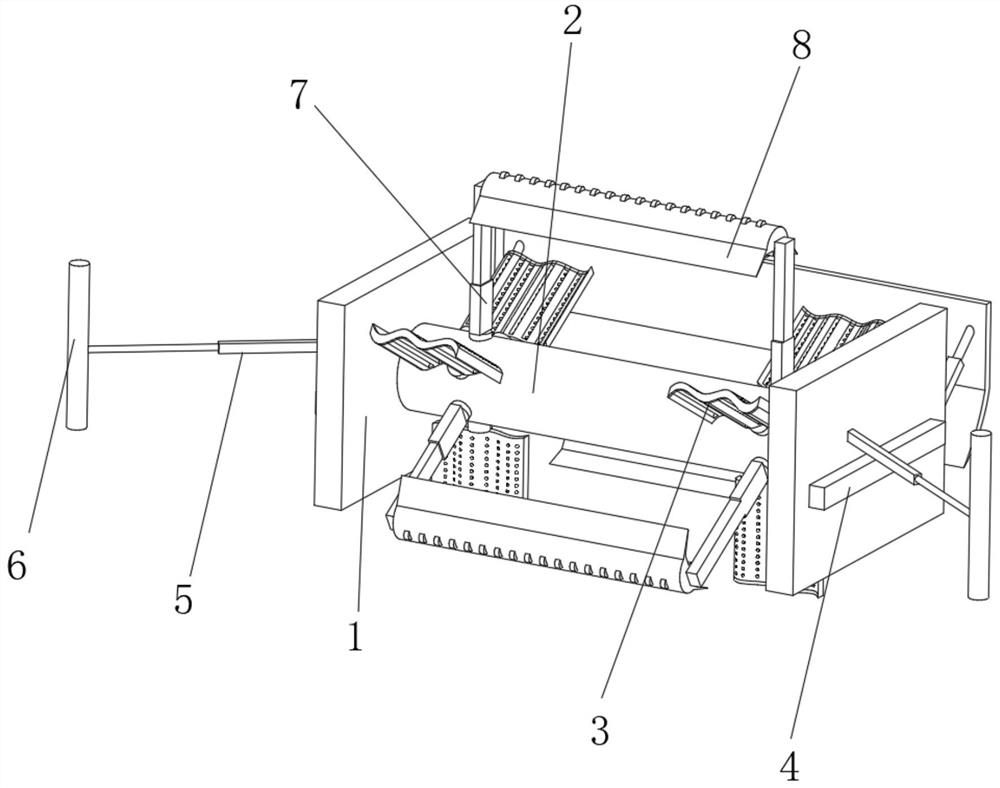

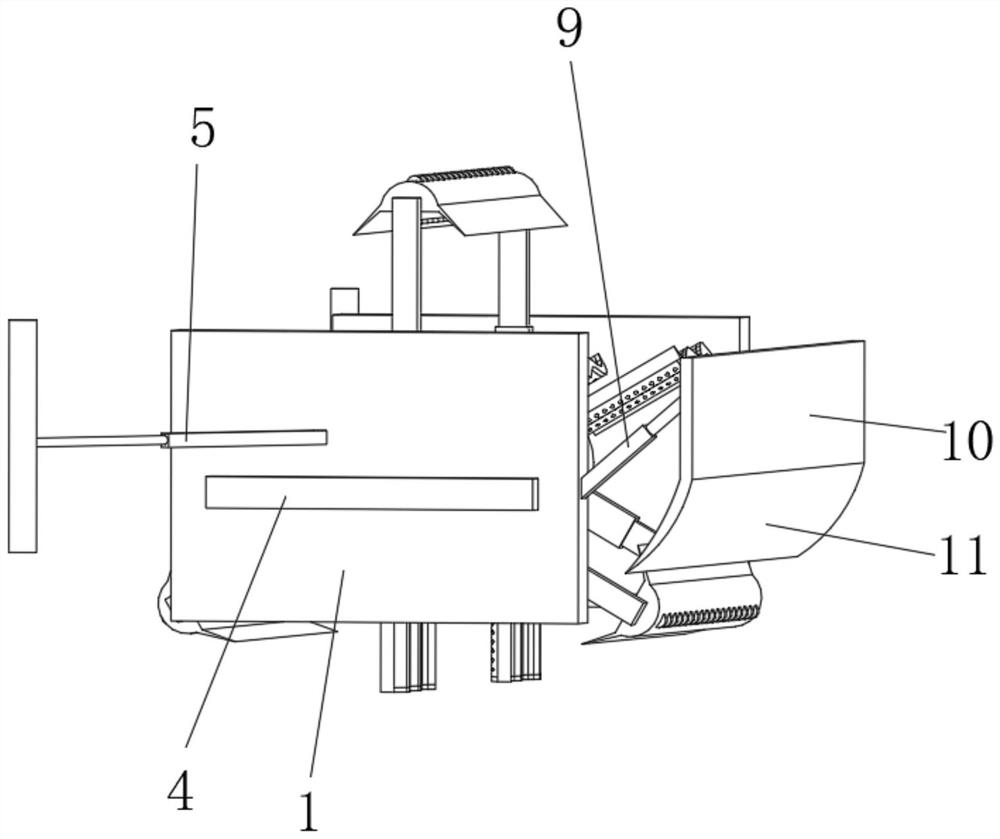

[0039] Such as Figure 1-3As shown, the present invention provides a technical solution: a device for clearing silt from a water channel, including a limiting outer frame 1, a drive shaft 2 is rotatably connected to the middle position of the inner limit of the outer frame 1, and the surroundings of the outer two ends of the drive shaft 2 The water diversion driving mechanism 3 is evenly and fixedly connected, and the middle position outside the drive shaft 2 is fixedly connected with a stable floating plate 4, and the middle of the outside of the drive shaft 2 and is located above the stable floating plate 4 is rotatably connected with a spring connecting rod 5, and the spring is connected One end of the rod 5 far away from the limit outer frame 1 is connected with a contact pressure roller 6, and the outer surface of the drive shaft 2 and the position between the water diversion drive mechanisms 3 are evenly and fixedly connected with a booster removal mechanism 7, and the to...

Embodiment 2

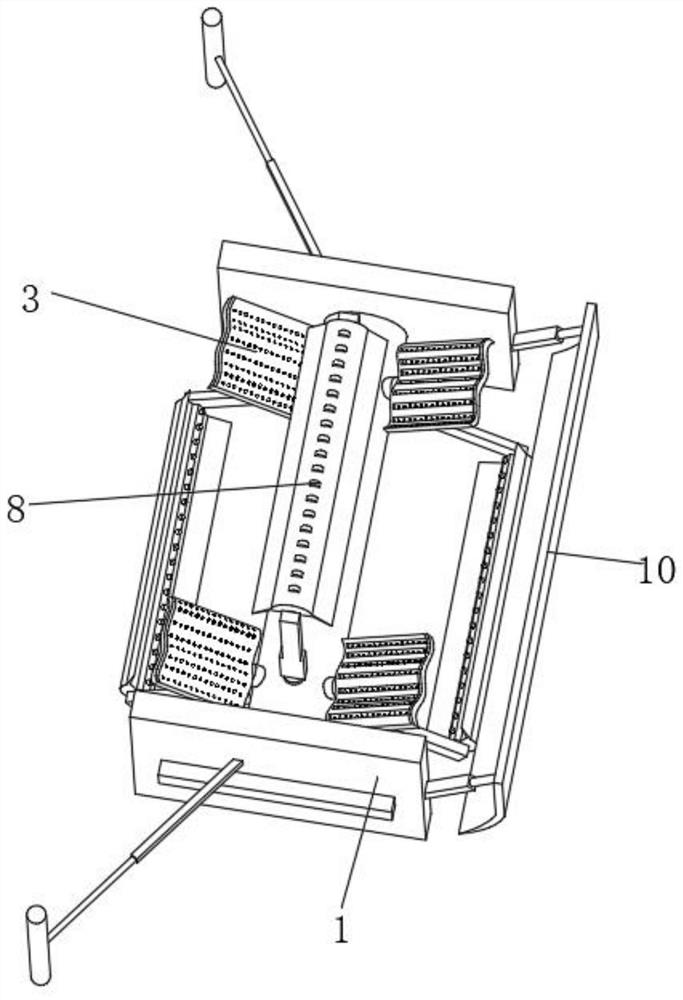

[0042] Such as Figure 4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: a device for clearing water canal silt, the water diversion drive mechanism 3 includes a drive baffle 301, and the bottom end of the drive baffle 301 is fixedly connected to the drive shaft 2 , the drive baffle 301 adopts a corrugated structure, and the surface of the drive baffle 301 is axially consistent with the drive shaft 2 .

[0043] The surface of one side of the driving baffle 301 is uniformly provided with a resistance-increasing inner groove 302 , and the inside of the resistance-increasing inner groove 302 is provided with a limiting perforation 303 , and the back of the limiting perforation 303 penetrates the driving baffle 301 . The water flow resistance area is increased to ensure the driving force for driving the shaft rod 2 to rotate.

Embodiment 3

[0045] Such as Figure 5 As shown, on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: a kind of water channel sludge cleaning device. The drive shaft 2 is fixedly connected, and the top inside the booster rod 71 is penetrated and slidably connected with an extruding connecting rod 72 .

[0046] A booster inner groove 73 is provided at a vertical position inside the booster pole 71, and the booster inner groove 73 adopts a tapered structure with a large top and a small bottom.

[0047] The extruding connecting rod 72 is rotatably connected with a drive blade 74 at a position close to the bottom, and the bottom end of the extruding connecting rod 72 is fixedly connected with a restricting cone block 75 , which is correspondingly arranged with the pressurized inner groove 73 . Increases fluidity during water discharge and collection to avoid clogging.

[0048] The vertical position inside the extruding connecting rod 72 is fixedl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com