Construction method for locating bracket of tunnel anchorage prestressed system

A technology for positioning brackets and construction methods, which is applied in the direction of erecting/assembling bridges, bridge parts, bridge materials, etc., which can solve the difficulty of controlling the construction accuracy of the prestressing system in the cave, the high requirements for the construction accuracy of the prestressing system, and the quality of the supporting steel truss Reliable decision-making basis and technical indicators, good assembly environment, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

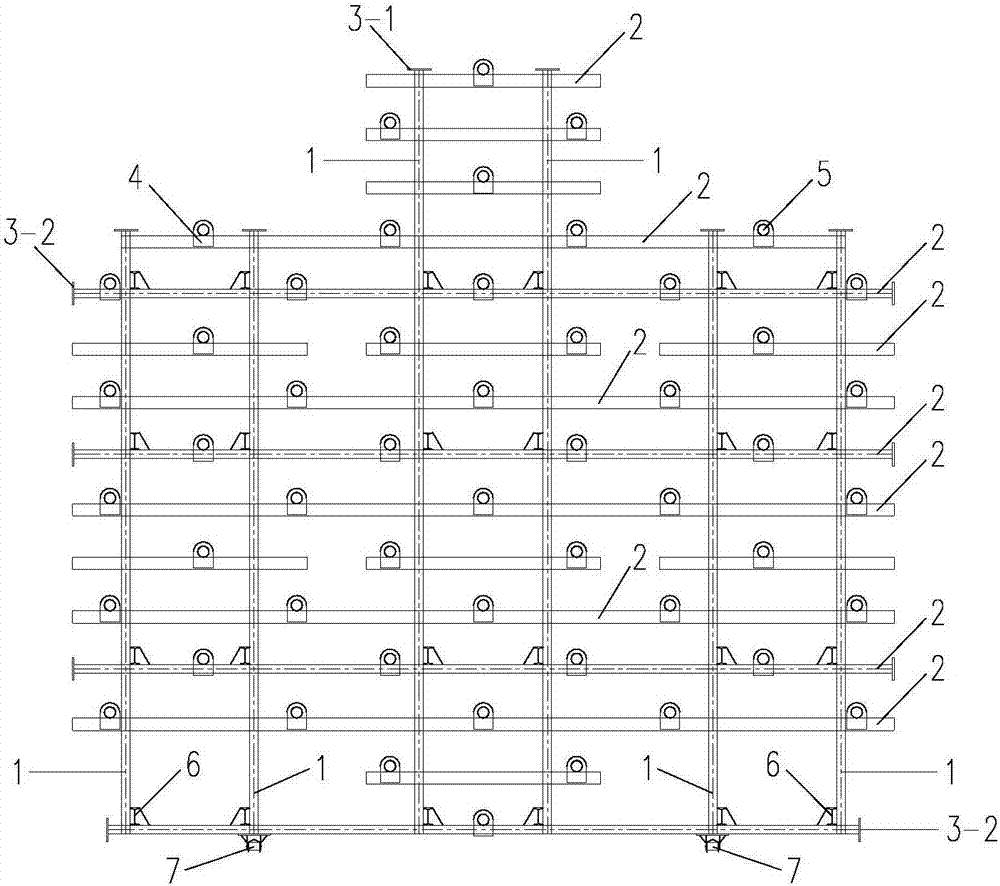

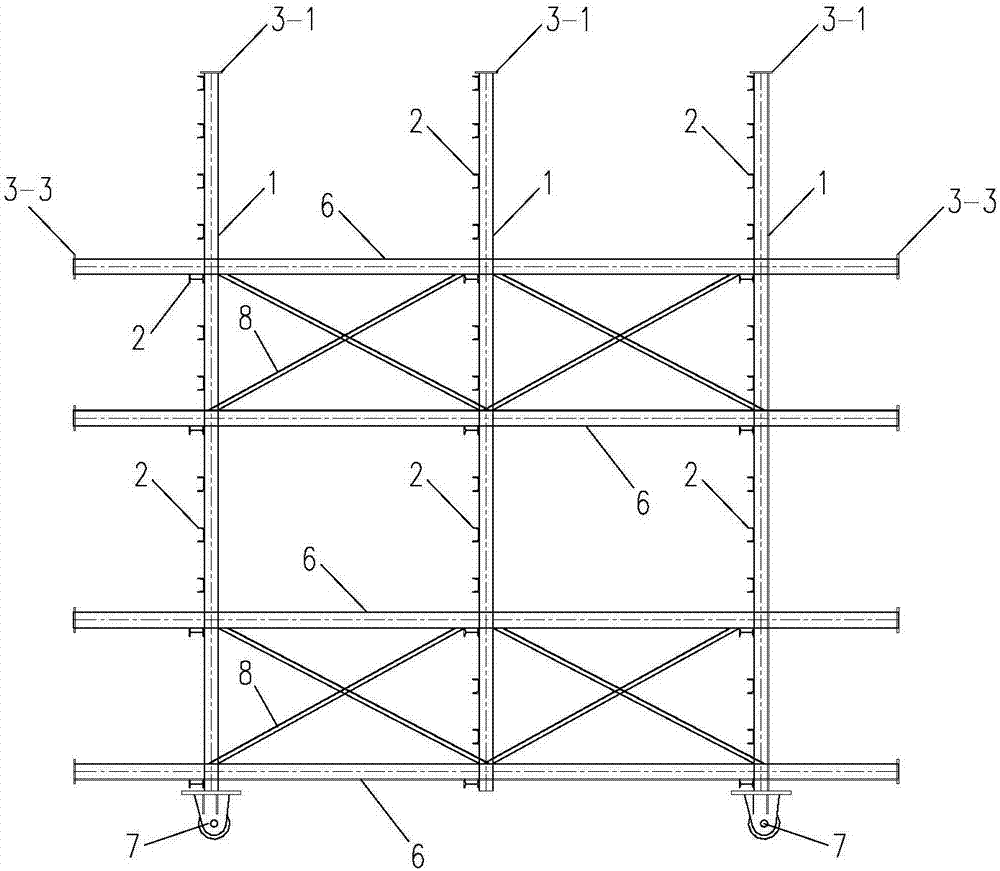

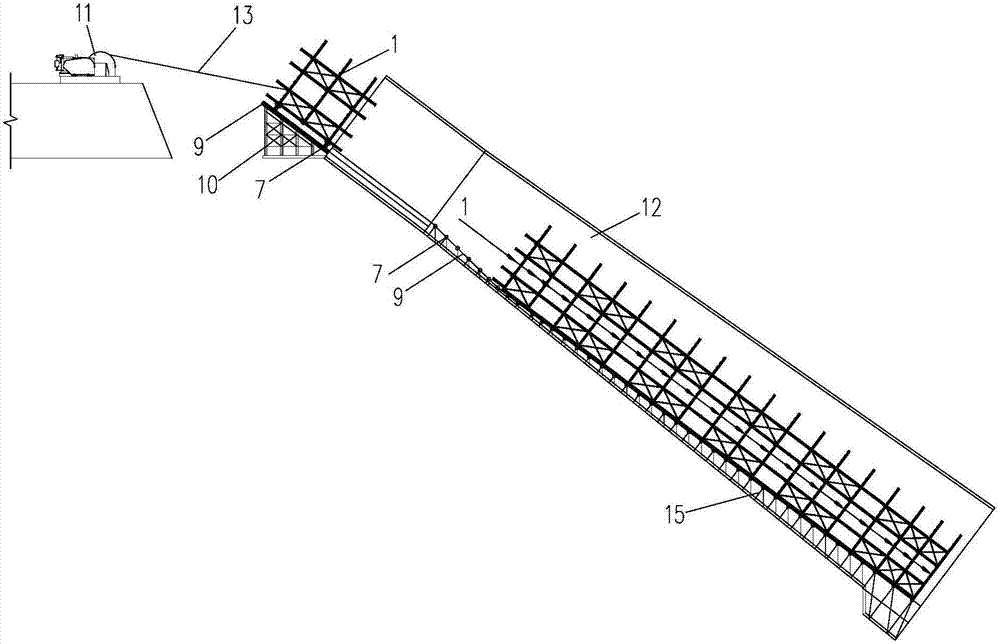

[0042] (1) Manufacturing positioning bracket truss unit, said positioning bracket truss unit includes 3 positioning bracket sheet units, each of said positioning bracket sheet unit includes a plurality of vertical rods 1 arranged in parallel and spaced in the vertical direction and all vertical The bottoms of the rods are all in a line. The vertical rods 1 are all made of I-steel to serve as the supporting structure of the positioning bracket and the frame unit. A plurality of horizontal rods are welded on the vertical rod 1 and spaced up and down in the horizontal direction. 2. The cross-bar 2 at the bottom and the cross-bar 2 at every two cross-bars 2 above the bottom-most cross-bar 2 are made of I-steel, and the remaining cross-bars 2 are made of channel steel and I-steel. The rods 2 are arranged in full length on all the vertical rods 1, and the cross rods 2 made of channel steel are alternately arranged in full length on all the vertical rods 1. This not only ensures the so...

Embodiment 2

[0054] (1) Manufacturing positioning bracket truss unit, the positioning bracket truss unit includes two positioning bracket sheet units, each of the positioning bracket sheet unit includes a plurality of vertical rods 1 arranged in parallel and spaced in the vertical direction and all vertical The bottoms of the rods are all in a line. The vertical rods 1 are all made of I-steel to serve as the supporting structure of the positioning bracket and the frame unit. A plurality of horizontal rods are welded on the vertical rod 1 and spaced up and down in the horizontal direction. 2. The cross-bar 2 at the bottom and the cross-bar 2 at every 3 cross-bars 2 above the bottom-most cross-bar 2 are made of I-steel, and the remaining cross-bars 2 are made of channel steel and I-steel. The rods 2 are arranged in full length on all the vertical rods 1, and the cross rods 2 made of channel steel are arranged in full length alternately on all the vertical rods 1. This can ensure the solid and ...

Embodiment 3

[0066] (1) Manufacturing positioning bracket truss unit, the positioning bracket truss unit includes 3 positioning bracket sheet units, each of the positioning bracket sheet unit includes a plurality of vertical rods 1 arranged in parallel and spaced in the vertical direction and all vertical The bottoms of the rods are all in a line. The vertical rods 1 are all made of I-steel to serve as the supporting structure of the positioning bracket and the frame unit. A plurality of horizontal rods are welded on the vertical rod 1 and spaced up and down in the horizontal direction. 2. The cross-bar 2 at the bottom and the cross-bar 2 at every two cross-bars 2 above the bottom-most cross-bar 2 are made of I-steel, and the remaining cross-bars 2 are made of channel steel and I-steel. The rods 2 are arranged in full length on all the vertical rods 1, and the cross rods 2 made of channel steel are alternately arranged in full length on all the vertical rods 1. This not only ensures the soli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com