Self-erecting guard wall structure of grid underground wall

An underground wall and self-supporting technology, applied in the field of construction, can solve the problems of adjacent projects and underground space waste, adverse effects of underground space utilization, large underground use area, etc., to achieve small excavation deformation, strong anti-seepage ability, and surrounding The effect of small environmental impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

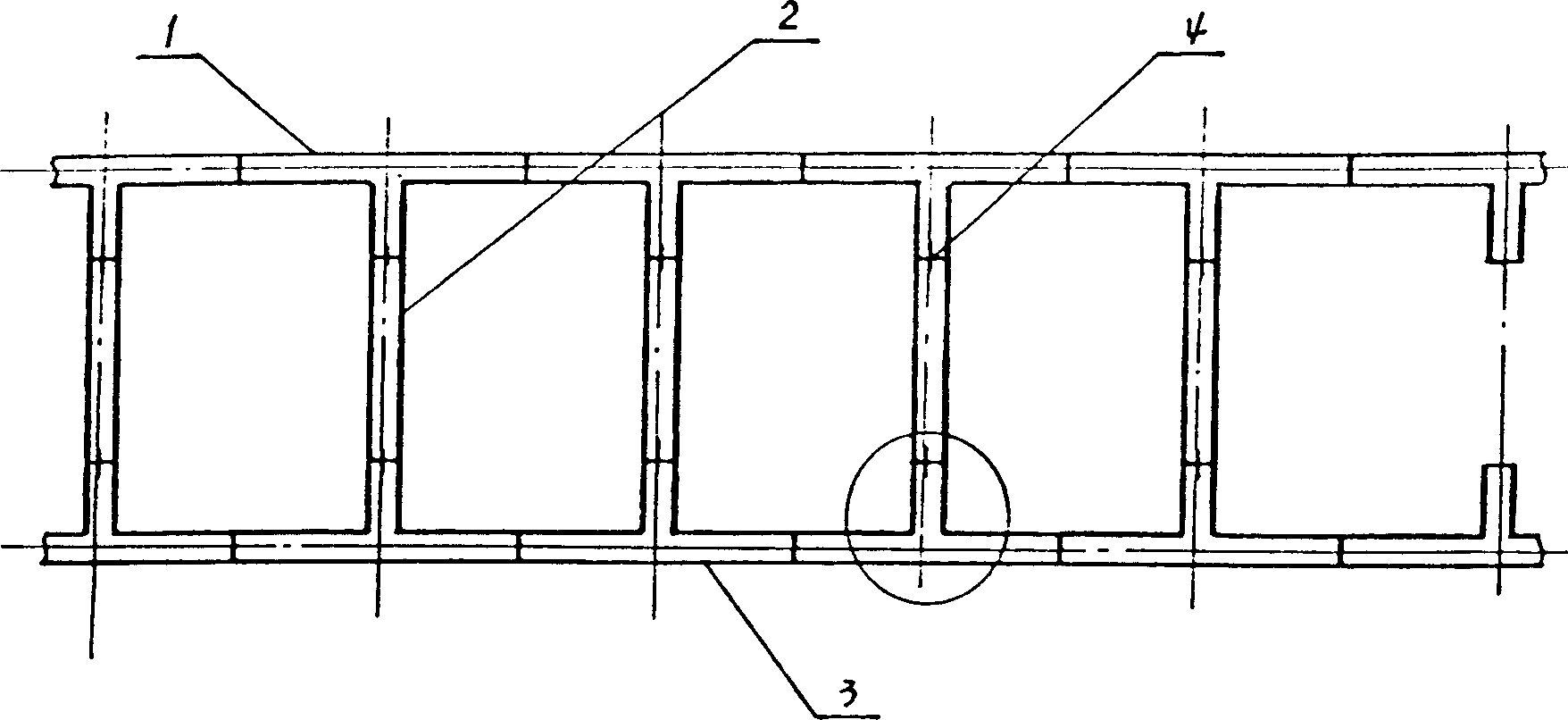

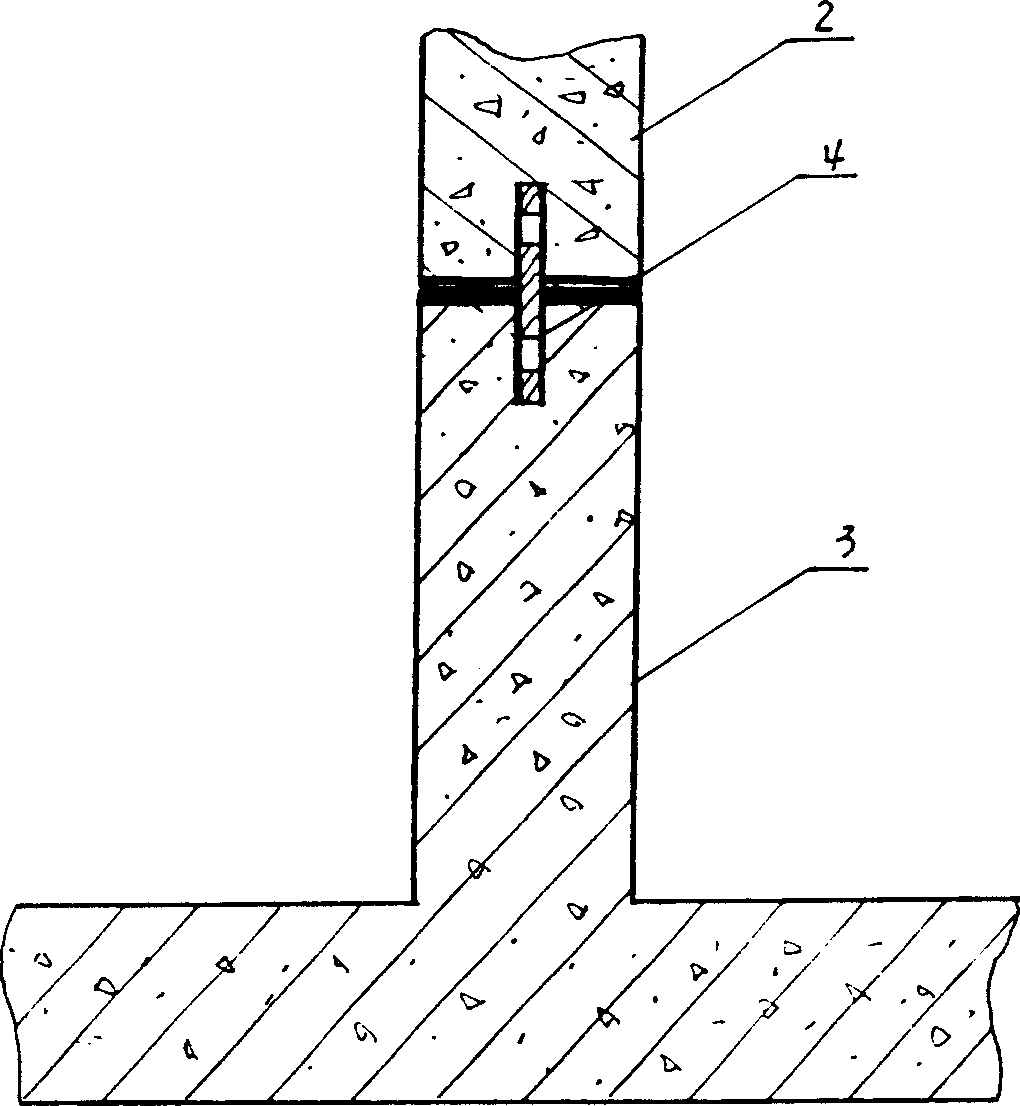

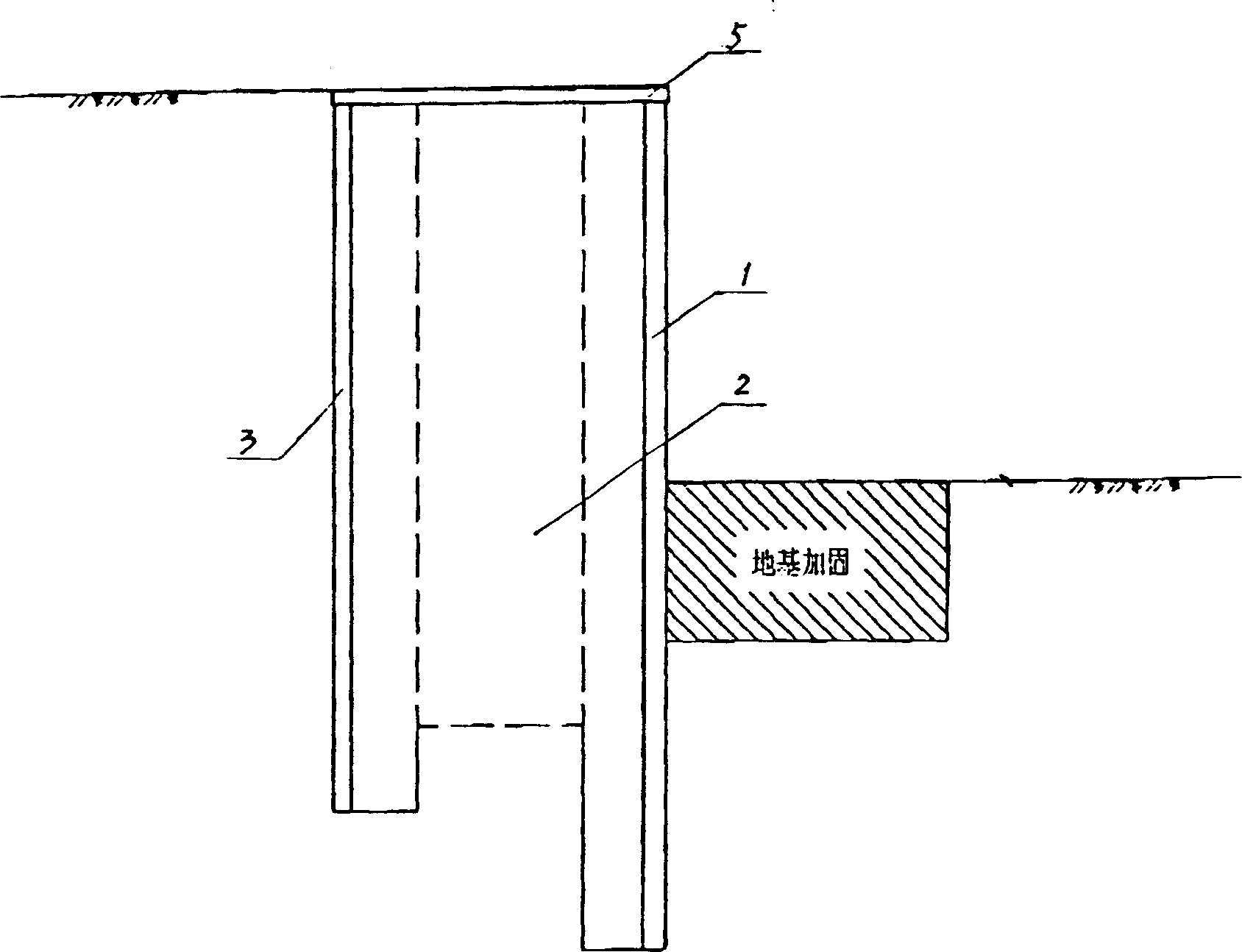

[0011] refer to figure 1 , 2 , 3, the present invention is made up of inner underground wall 1 (T-shaped groove section), middle underground wall 2 (middle groove section), outer underground wall 3 (T-shaped groove section), perforated steel plate 4, roof 5, and inner underground wall 1 The sections of the outer underground wall 3 are arranged in several T-shape, and the sections of the outer underground wall 3 are arranged in several T-shape and correspond to the T-shaped section of the inner underground wall 1. There is a font middle between the T-shaped sections corresponding to the inner and outer underground walls 1 and 3. The underground wall 2 and the middle underground wall 2 are connected to the corresponding T-shaped section of the inner and outer underground walls through the perforated steel plate 4, and the top plate 5 is arranged on the top of the inner underground wall, the middle underground wall, and the outer underground wall to connect them together. A perm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com