Deeply-buried pool construction method for gridded underground continuous-wall foundation pit support

An underground diaphragm wall and foundation pit enclosure technology, applied in water conservancy engineering, infrastructure engineering, excavation, etc., can solve the problems of inability to meet the stability and safety of the pool structure, a large amount of construction waste, etc., to avoid construction waste and project progress. Fast and simple construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

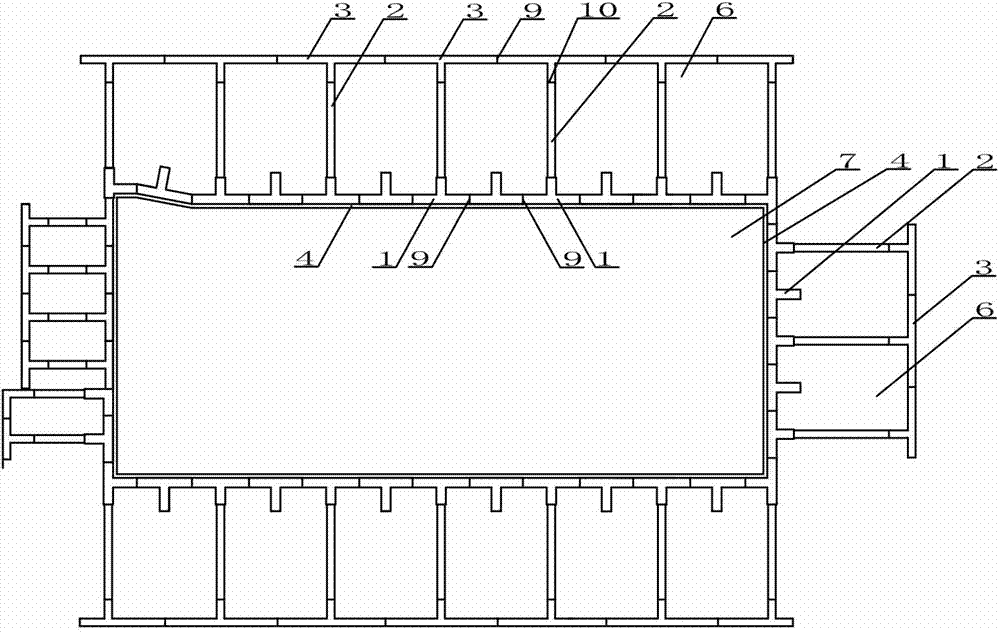

[0015] The present invention will be further described below with certain engineering pond, and this pond length is 68m, width 28m, and excavation depth is 21m.

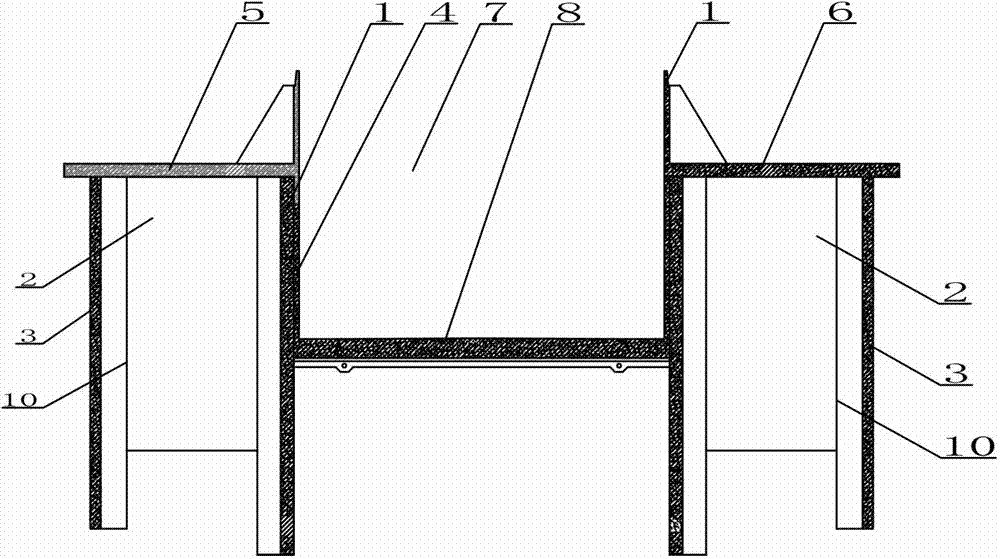

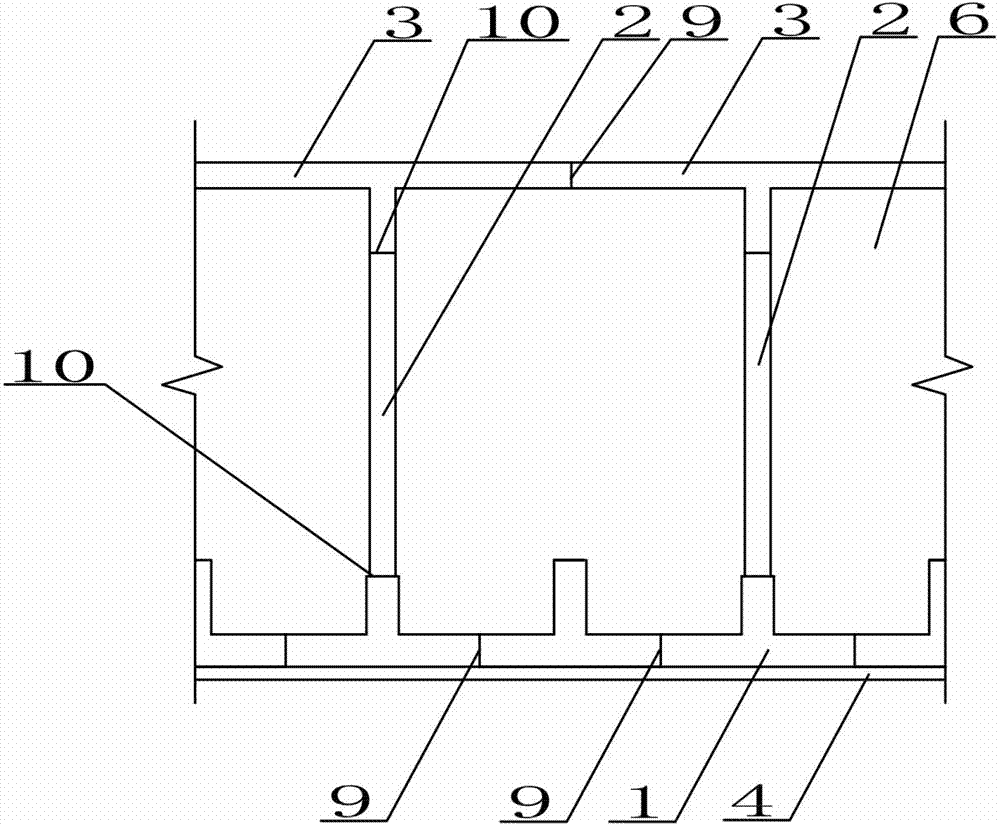

[0016] See attached figure 1 ~ attached figure 2 , the present invention consists of a grid-shaped underground continuous wall 6 and a deep buried pool 7, the grid-shaped underground continuous wall 6 is a front wall 1 and a rear wall 3 and a web 2 arranged between the front wall 1 and the rear wall 3, The top plate 5 is connected as a grid-shaped ground wall of the overall structure; the deep-buried pool 7 is a "U"-shaped open pool formed by the pool side wall 4 and the pool bottom plate 8, and the deep-buried pool 7 is formed by a lattice-shaped underground continuous wall 6 In order to resist the lateral force retaining structure, the vertical earthwork excavation without internal support structure is carried out in the foundation pit enclosure formed by the lattice underground diaphragm wall 6, and its specific...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com