Corrosion-resistance seamless stainless steel pipe and preparation method thereof

A stainless steel tube, stainless steel technology, applied in the field of austenitic stainless steel, can solve the problem of low corrosion resistance, achieve the effect of improving strength, eliminating component segregation, and improving stress corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] In this embodiment, an ultra-low carbon austenitic stainless steel has a chemical composition in terms of mass percentage: 0.017% carbon, 0.2% nitrogen, 1.75% manganese, 19.4% chromium, 10.6% nickel, 0.39% silicon, and 1.62% aluminum , tantalum 2.01%, vanadium 0.64%, hafnium 2.13%, titanium 0.69%, cobalt 0.28%, tungsten 3.04%, molybdenum 1.86%, selenium 0.61%, and the balance is iron.

Embodiment 2~5

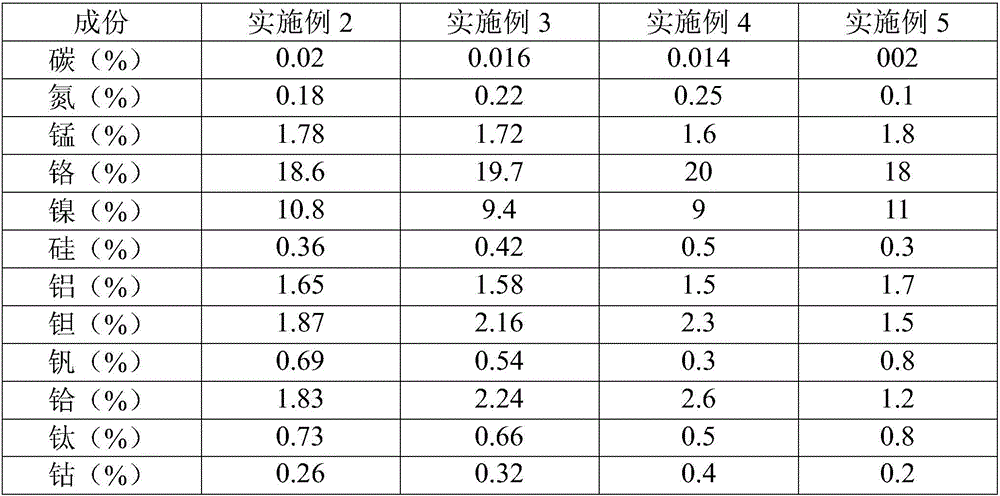

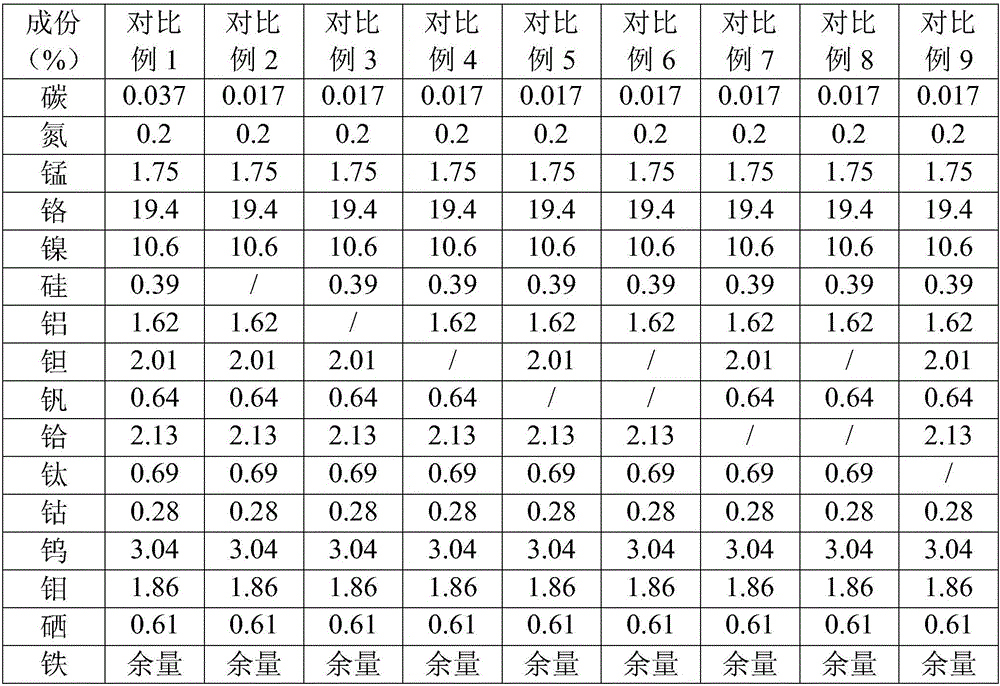

[0066] The chemical composition of the ultra-low carbon austenitic stainless steel in Examples 2-5 is shown in Table 1 in terms of mass percentage.

[0067] The chemical composition table of the ultra-low carbon austenitic stainless steel of table 1 embodiment 2~5

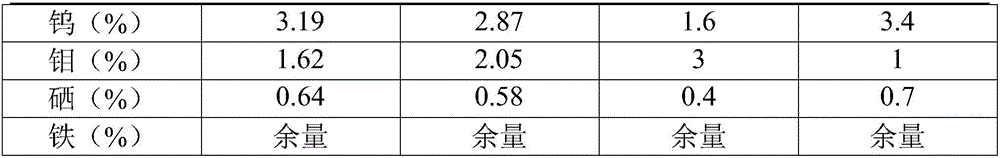

[0068]

[0069]

Embodiment 6

[0077] Utilizing the austenitic stainless steel materials of Examples 1-5 and Comparative Examples 1-19 respectively to prepare corrosion-resistant seamless stainless steel pipes, comprising the following steps:

[0078] (1) primary refining

[0079] ①: According to the preset mass percentage, put manganese, nickel, chromium, molybdenum, selenium, aluminum and iron in an electric furnace or a converter, and smelt at 1350-1420°C until all components are completely melted to obtain smelting liquid A;

[0080] ②: Put tantalum, hafnium, tungsten, titanium, vanadium and cobalt in an electric furnace or a converter according to the preset mass percentage, and smelt at 1480-1620°C until all components are completely melted to obtain smelting solution B;

[0081] ③: Raise the temperature of smelting liquid B to 1550-1750°C, and add carbon, nitrogen and silicon to smelting liquid B according to the preset mass percentage, and continue smelting for 3 to 4 hours to obtain smelting liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com