Sleeve valve pipe reinforcing construction method for mountain

A construction method and technology of sleeve valve pipes, which are applied in tunnel mountain biased areas and underground excavation engineering construction fields, can solve problems such as arc cracks on the surface, local steel frame distortion, and initial support cracking in the cave, etc., to achieve saving The effect of cost, fast project progress and less interference factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

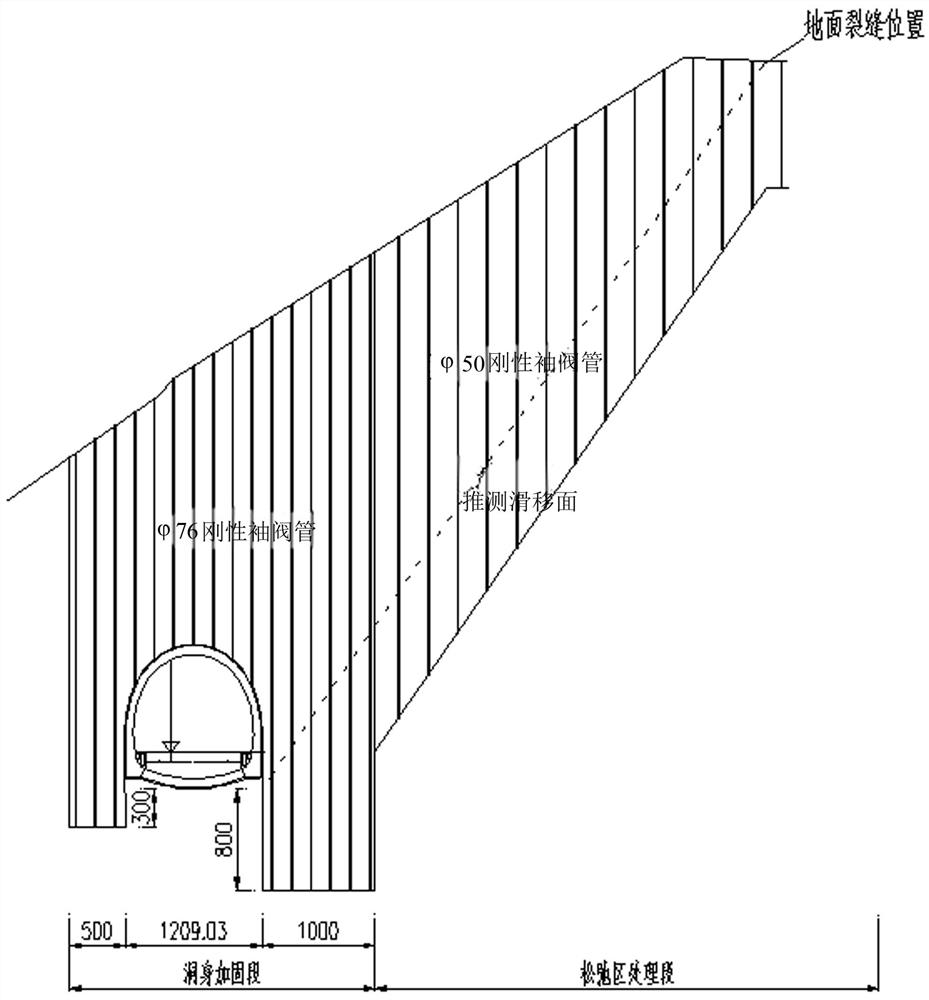

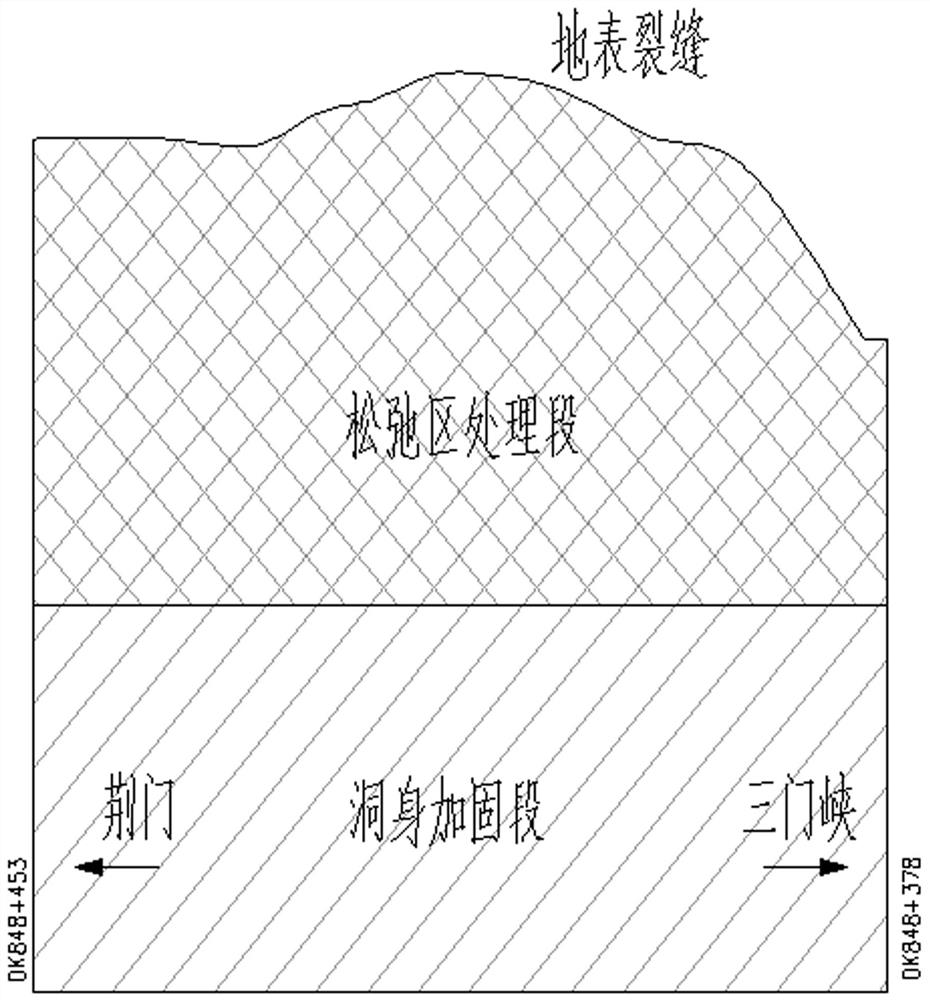

[0020] The specific construction situation is taken as an example below to describe the construction method in detail.

[0021] 1. Hongya Tunnel of Menghua Railway

[0022] 1.1 Project overview

[0023] Hongya Tunnel is located in Chongyang Town, Xixia County, Nanyang City, Henan Province. The entrance of Hongya Tunnel is connected to Dazhaigou Middle Bridge, and the exit is connected to Hongyagou Bridge. The tunnel is located about 400m on the right side of the existing Ningxi Railway. 312 is located on the left side of the line, and its direction is roughly consistent with the direction of the line, but most of them are far away from the line, and the traffic is relatively inconvenient. The tunnel adopts a single-hole double-track type, which is a double-track ballast track. The building length is 190.3m, the tunnel length is 184.8m, the entrance mileage is DK847+289.7, and the exit mileage is DK847+474.5. 43.5m, including 30 meters of surrounding rock for grade IV, and 15...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com