Construction method of industrialized short-line prefabrication and assembly of urban overpass

A technology of prefabricated assembly and construction method, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of environmental damage around the construction site, increase project cost, long construction period, etc. small, low-impact effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

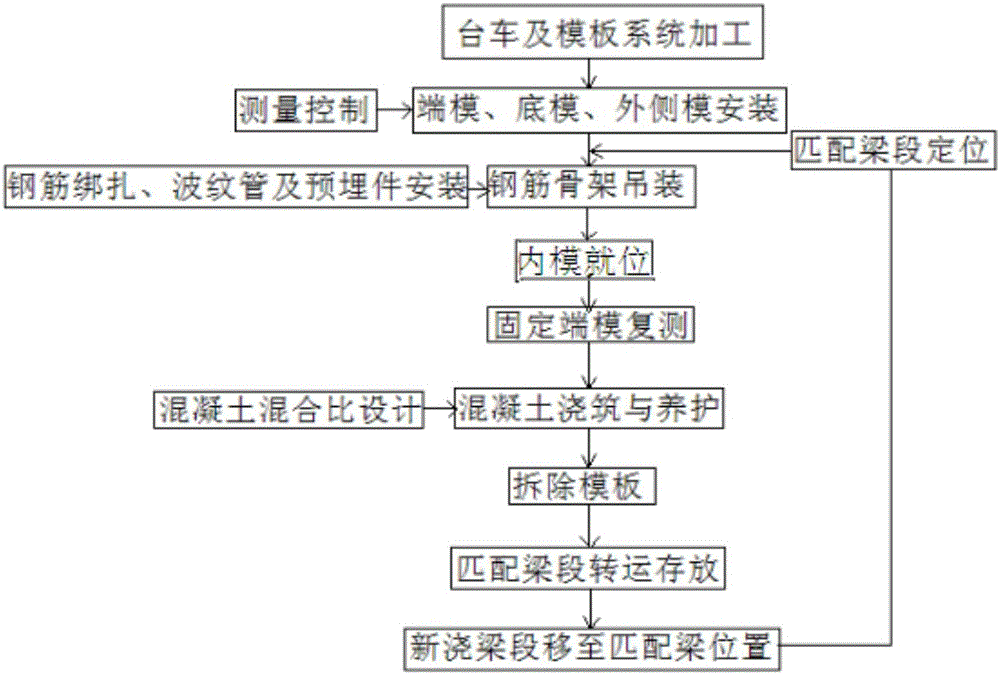

[0027] The detailed construction process is shown in the figure. Specifically, processing of trolley and formwork system, installation of end formwork, bottom formwork and outer formwork, measurement and control before installation, hoisting of steel frame, steel bar binding and installation of corrugated pipes and embedded parts before hoisting, and then the inner formwork is in place and fixed End formwork retesting, concrete pouring and maintenance after concrete mix ratio design, formwork removal, matching beam section transfer and storage, new cast beam section moving to matching beam position, and then repeat matching beam positioning at the steel skeleton hoisting position.

[0028] This construction method is applicable to bridge engineering, municipal engineering, various overpass bridges, overroad bridges and narrow construction sites, etc., which need to be constructed without affecting traffic flow.

[0029] The short-line method is to accurately calculate the defl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com