Method for extracting potassium co-production liquid salt from concentrated seawater

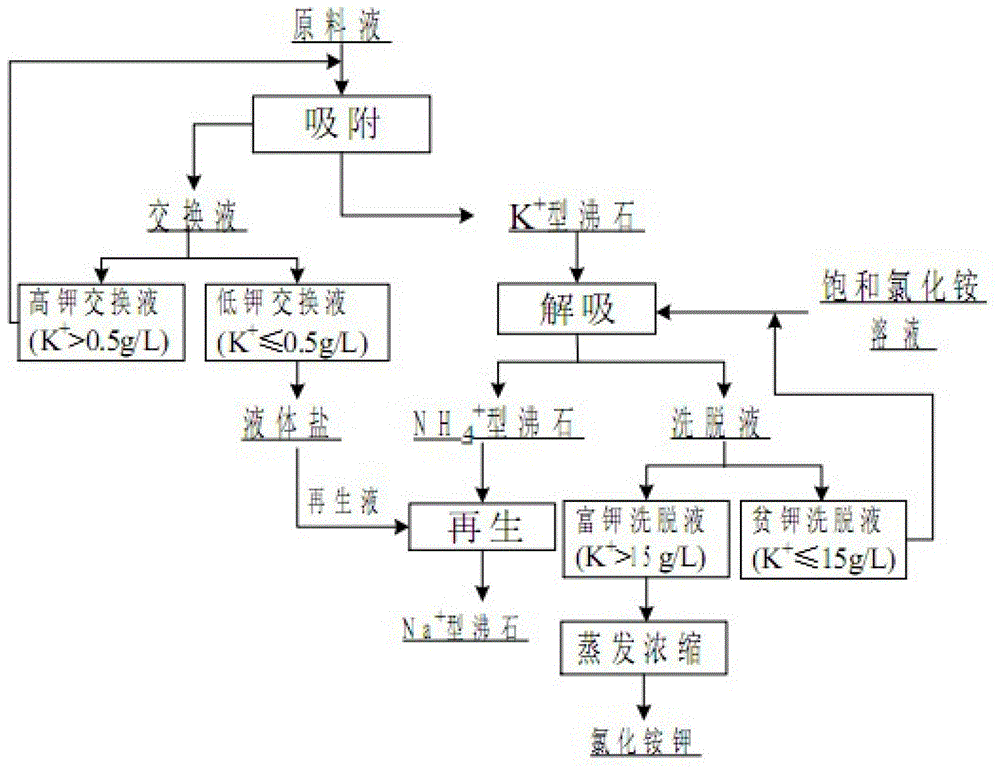

A technology of concentrated seawater and liquid salt, applied to potash fertilizers, alkali metal chlorides, inorganic fertilizers, etc., can solve the problems of expensive extraction materials, complicated operating procedures, and large material turnover, and achieve improved comprehensive utilization and energy consumption. Low, reduce the effect of potassium extraction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical scheme of the present invention will be further described in conjunction with the following examples:

[0018] Take 4 glass exchange columns, the size is 15mm×1400mm, each exchange column contains Na + Type natural clinoptilolite 150g, 4 ion-exchange columns with natural clinoptilolite are connected in series. Get 8L of concentrated seawater after extracting bromine, magnesium and calcium as the raw material solution, and the potassium ion K in the raw material solution + The concentration is 2.69g / L, SO 4 2- The concentration is 4.88g / L, Ca 2+ The concentration is 0.60g / L.

[0019] The raw material liquid passes through the ion exchange column in series from bottom to top, the flow rate is 16mL / min, the potassium ion K in the raw material liquid + Adsorbed onto the zeolite in the ion exchange column, Na + Type zeolites become K + type zeolite. Collect the exchange liquid flowing out from the ion exchange column, and take samples every 15 minutes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com