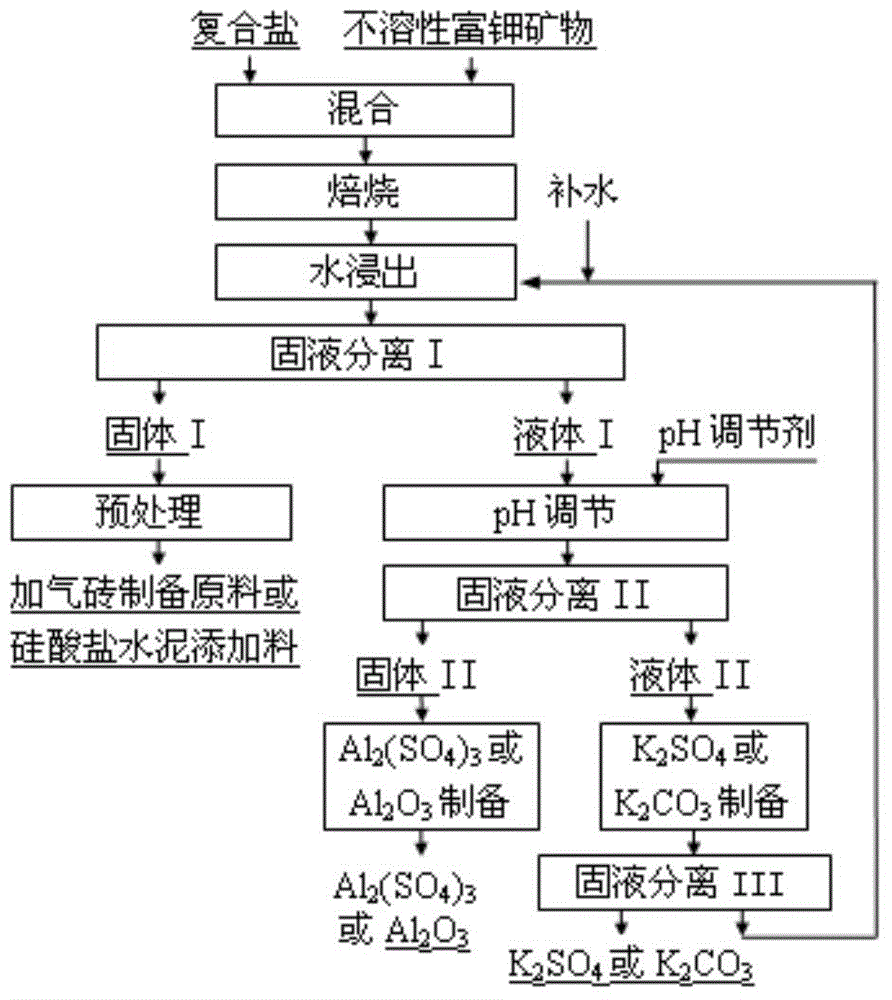

Composite salt treatment and comprehensive utilization process of insoluble potassium-enriched minerals

A compound salt, potassium-rich technology, applied in the direction of aluminum sulfur compounds, carbonate preparations, sulfate/bisulfate preparation, etc., can solve the problems of long reaction cycle, low efficiency, complicated separation of impurities, high raw material cost, and achieve industrial The effect of broad chemical prospect, good environmental compatibility and lower production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024]Mix 1000g of calcium sulfate and 400g of calcium carbonate with 100g of sodium nitrate to form a composite salt, mix it evenly with 1000g of potassium feldspar ore powder, control the roasting temperature at 1100°C, roast for 1.5h, and soak the roasted material in water for 4h, control the water The mass ratio to the raw ore is 6:1, and solid I and 5600mL liquid I are obtained after filtration. The content of Al in liquid I is 7367mg / L, the content of K is 11620mg / L, the content of Na is 3600mg / L, and the content of other impurities is less than 30mg / L.

[0025] Liquid I uses CO 2 After the pH was adjusted to 8.5, filtration and separation were carried out to obtain 119 g of solid II and 5540 mL of liquid II. The Al content in liquid II was 183 mg / L, and the separation of K and Al was achieved well.

[0026] Al content in solid II is 33.20%, converted into Al(OH) 3 The content is 95.5%, and the contents of other components are shown in Table 1; the solid II is passed t...

Embodiment 2

[0031] Mix 700g of calcium sulfate and 600g of calcium nitrate, and 110g of sodium silicate to form a composite salt, mix evenly with 1000g of potassium feldspar ore powder, control the roasting temperature at 1400°C, roast for 0.5h, and soak the roasted material in water for 2.5h. The mass ratio of water to raw ore is controlled to be 10:1, and solid I and liquid I are obtained after filtration.

[0032] Liquid I uses H 2 SO 4 After adjusting the pH to 5.5, filter and separate to obtain solid II and liquid II, and Al(OH) in solid II 3 The content is 85%, and the Al content in liquid II is 254mg / L.

[0033] Solid II uses Al(OH) 3 The typical process of production, that is, the Bayer method, the obtained Al(OH) 3 Preparation of sandy Al by roasting 2 o 3 ; Liquid II is processed by alcohol salting-out method (volume ratio of alcohol and liquid II is 0.6:1), centrifugal separation, drying and other processes to obtain K 2 SO 4 product, K 2 SO 4 K in the product 2 The ...

Embodiment 3

[0035] The composite salt of 1600g calcium sulfate, 250g calcium carbonate and 150g sodium sulfite is mixed evenly with 1000g potassium feldspar ore powder, the roasting temperature is controlled at 1450°C, roasted for 2h, and the roasted material is soaked in water for 1.5h (the mass ratio of water to raw ore 8:1), after filtration, solid I and 7800mL liquid I were obtained, and the analysis results of I liquid I are shown in Table 2.

[0036] Liquid I uses H 2 SO 4 After adjusting the pH to 8.0, filter and separate to obtain 132g of solid II and 7750mL of liquid II. The above separation process can separate Al and K very well. After analysis, Al(OH) in solid II 3 content>90%, Al content in liquid II is lower than 250mg / L.

[0037] Solid II is reacted with NaOH solution to control the Ke ratio to 1.3-1.6 and the carbon content to be 12h to obtain Al(OH) 3 Sandy Al was obtained after roasting 2 o 3 ; Liquid II is treated with alcohol salting-out method, the volume ratio o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com