Process for producing monopotassium phosphate by taking potassium nitrate as raw material

A technology of potassium dihydrogen phosphate and ammonium dihydrogen phosphate, which is applied in the fields of phosphorus compounds, inorganic chemistry, non-metallic elements, etc., can solve problems such as difficult removal of chloride ions, and achieve the effects of reducing production costs and avoiding seedling burning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

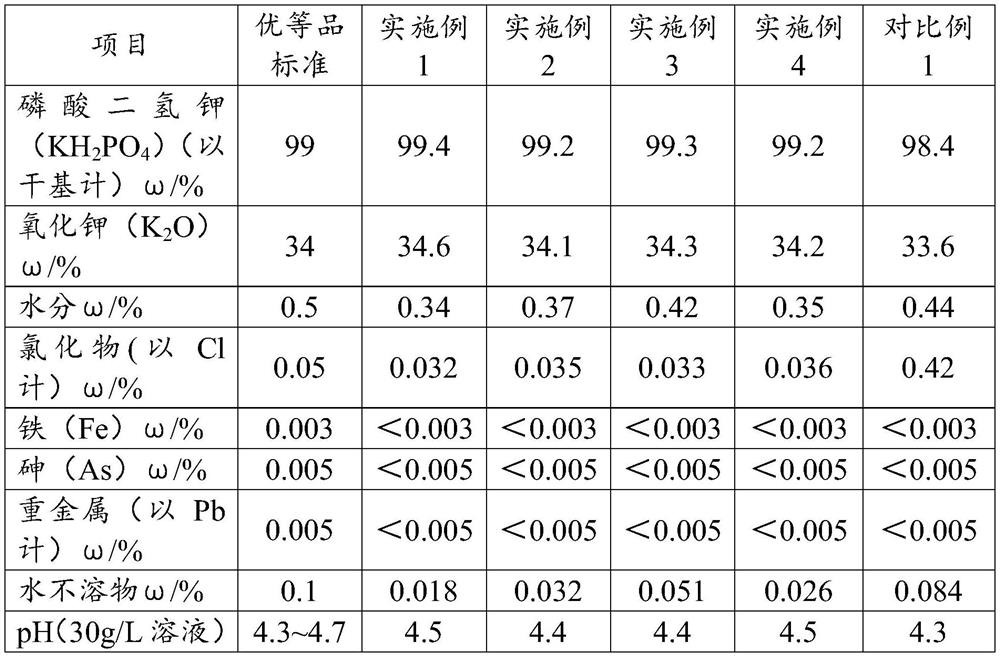

Embodiment 1

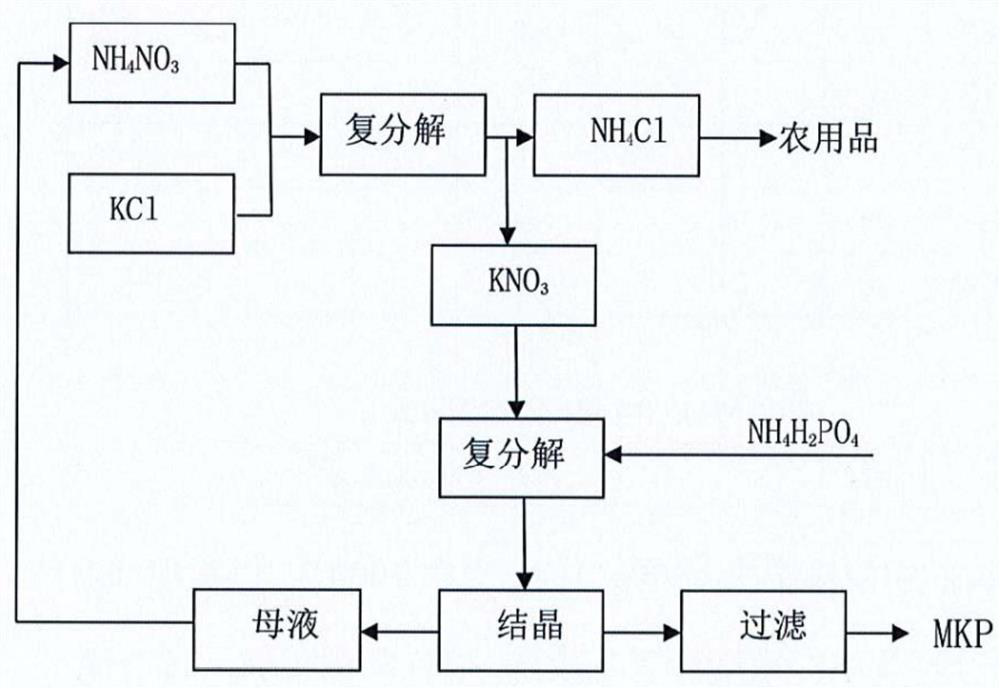

[0049] The production steps of potassium dihydrogen phosphate are:

[0050] a. in the reactor, be that the ammonium nitrate of 1.2:1 is mixed with potassium chloride by mol ratio, metathesis reaction takes place and obtains potassium nitrate and ammonium chloride mixture;

[0051] B. cooling and crystallizing the reaction mixture of step a, filtering to obtain potassium nitrate solid and ammonium chloride solution;

[0052] c. the potassium nitrate solid obtained in the step b is washed and recrystallized to obtain the potassium nitrate product;

[0053] d. the potassium nitrate product that dissolving step c obtains obtains density and is 1.2g / cm 3 Potassium nitrate solution, add ammonium dihydrogen phosphate to the potassium nitrate solution and stir, concentrate until the slurry density is 1.4g / cm 3 ;

[0054] e. The solution after the reaction in step c is cooled and then centrifugally filtered to obtain potassium dihydrogen phosphate crystals.

Embodiment 2

[0056] Compared with embodiment 1, the difference of the production step of potassium dihydrogen phosphate only is:

[0057] In step a, the molar ratio of ammonium nitrate to potassium chloride is 1.1:1.

Embodiment 3

[0059] Compared with embodiment 1, the difference of the production step of potassium dihydrogen phosphate only is:

[0060] In step d, the density of potassium nitrate solution is 1.25g / cm 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com