Method for preparing potassium fluoride from crude potassium bifluoride

A technology of potassium hydrogen fluoride and potassium fluoride, applied in the field of preparing potassium fluoride, which can solve problems such as more mixing, easy hardening, and reduced activity of potassium fluoride, achieve good economic value and social value, reduce production costs, and alleviate pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

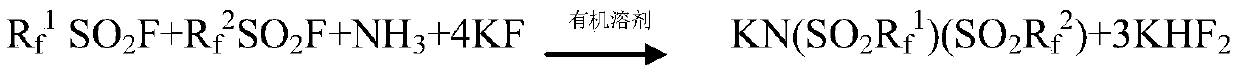

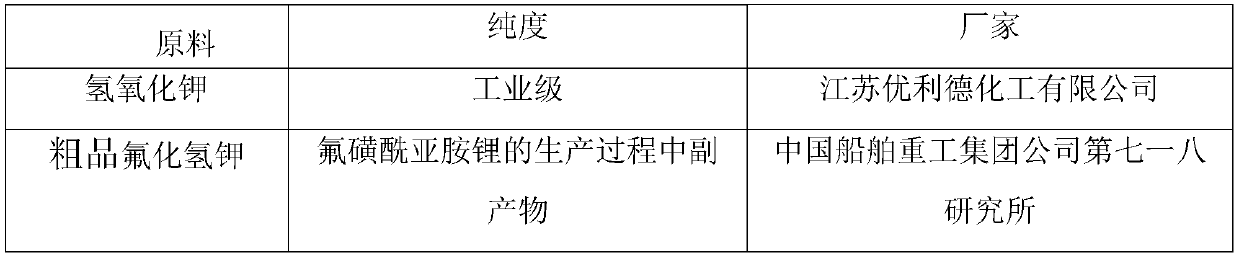

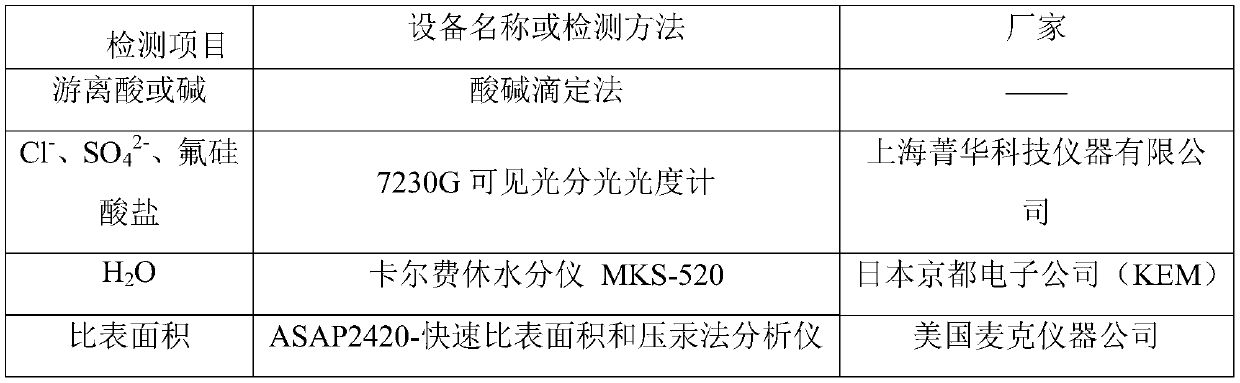

Method used

Image

Examples

Embodiment 1

[0033] In this embodiment, the material in contact with the reaction kettle and the material is Hastelloy, and the composition and mass percentage of by-product potassium hydrogen fluoride are: potassium hydrogen fluoride 93.7%, potassium fluoride 4.5%, organic solvent 1.8%, organic solvent is dichloro methane.

[0034] A kind of method utilizing crude product potassium hydrogen fluoride to prepare potassium fluoride comprises the following steps:

[0035] (1) Add the crude potassium hydrogen fluoride into the reaction kettle, and dry it under stirring; wherein, the drying temperature is 80°C, the pressure is -0.096MPa, and the time is 10h;

[0036] (2) adding water to the dried crude product potassium bifluoride to form a suspension whose mass concentration is 50%;

[0037] (3) dripping mass concentration in the suspension under stirring is the potassium hydroxide aqueous solution of 45% to react, when the pH of the solution is 9, the reaction ends; wherein, the composition ...

Embodiment 2

[0043] In this embodiment, the material in contact with the reaction kettle is made of Hastelloy, and the composition and mass percentage of by-product potassium hydrogen fluoride are: potassium hydrogen fluoride 93.6%, potassium fluoride 4.8%, organic solvent 1.6%, organic solvent is acetonitrile.

[0044] A kind of method utilizing crude product potassium hydrogen fluoride to prepare potassium fluoride comprises the following steps:

[0045] (1) Add the crude potassium hydrogen fluoride into the reaction kettle, and dry it under stirring; wherein, the drying temperature is 120°C, the pressure is -0.096MPa, and the time is 4h;

[0046] (2) adding water to the dried crude product potassium bifluoride to form a suspension whose mass concentration is 50%;

[0047] (3) dripping mass concentration in the suspension under stirring is the potassium hydroxide aqueous solution of 45% to react, when the pH of the solution is 9, the reaction ends; wherein, the composition and the mass f...

Embodiment 3

[0053] In this embodiment, the material in contact with the reaction kettle and the material is Hastelloy, and the composition and mass percentage of by-product potassium hydrogen fluoride are: potassium hydrogen fluoride 93.5%, potassium fluoride 4.5%, organic solvent 2%, organic solvent is triethyl amine.

[0054]A kind of method utilizing crude product potassium hydrogen fluoride to prepare potassium fluoride comprises the following steps:

[0055] (1) Add the crude potassium hydrogen fluoride into the reaction kettle, and dry it under stirring; wherein, the drying temperature is 90°C, the pressure is -0.090MPa, and the time is 5h;

[0056] (2) adding water to the dried crude product potassium bifluoride to form a suspension whose mass concentration is 50%;

[0057] (3) dripping mass concentration in the suspension under stirring is the potassium hydroxide aqueous solution of 45% to react, when the pH of the solution is 10.5, the reaction ends; wherein, the composition and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com