Potassium sulfate crystal growth accelerant and application thereof

A technology of crystal growth and accelerator, applied in the direction of alkali metal sulfite/sulfite, alkali metal compound, inorganic chemistry, etc., can solve the problems of inconvenient operation, irritation, occupational diseases of staff, etc., and achieve cost saving. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] In the aqueous solution that potassium ion concentration is 128g / L, add ammonium sulfate solid (the mass ratio of ammonium sulfate and potassium ion=2.7) and potassium sulfate crystal growth accelerator (the mass ratio=0.052 of accelerator and potassium ion, crystal accelerator consists of : The mass ratio of sodium tripolyphosphate, diammonium hydrogen phosphate, magnesium sulfate, urea and sodium chloride is 0.25:0.15:0.32:0.08:0.20), after stirring for 300min, filter, the filter residue enters the potassium sulfate refining process, and adds wet residue 80% by weight of ammonia solution with pH=8.5 was stirred and refined for 30 minutes, filtered and dried to obtain potassium sulfate product.

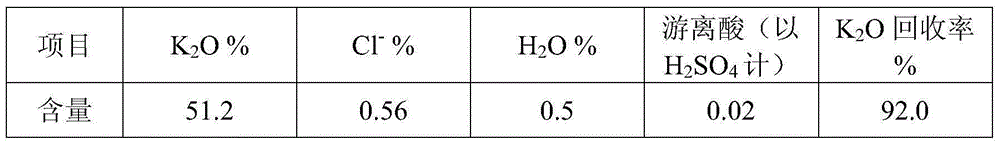

[0036] Table 1.1 is the potassium sulfate product quality data that embodiment 1 produces

[0037]

Embodiment 2

[0039] In the aqueous solution that potassium ion concentration is 128g / L, add ammonium sulfate solid (the mass ratio of ammonium sulfate and potassium ion=2.7) and potassium sulfate crystal growth promoter (the mass ratio=0.078 of accelerator and potassium ion, crystal promoter consists of : The mass ratio of sodium tripolyphosphate, diammonium hydrogen phosphate, magnesium sulfate, urea and sodium chloride is 0.25:0.15:0.32:0.08:0.20), after stirring for 300min, filter, the filter residue enters the potassium sulfate refining process, and adds wet residue 80% by weight of ammonia solution with pH=8.5 was stirred and refined for 30 minutes, filtered and dried to obtain potassium sulfate product.

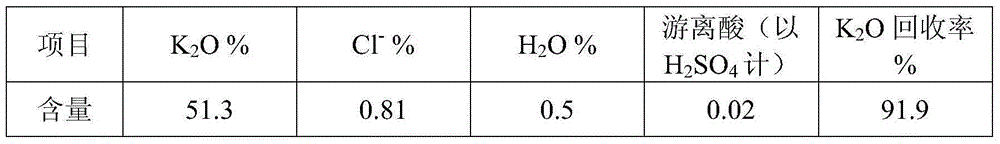

[0040] Table 2.1 is the potassium sulfate product quality data that embodiment 2 produces

[0041]

Embodiment 3

[0043] In the aqueous solution that potassium ion concentration is 128g / L, add ammonium sulfate solid (the mass ratio of ammonium sulfate and potassium ion=3.05) and potassium sulfate crystal growth promoter (the mass ratio=0.065 of accelerator and potassium ion, crystal promoter consists of : The mass ratio of sodium tripolyphosphate, diammonium hydrogen phosphate, magnesium sulfate, urea and sodium chloride is 0.25:0.15:0.32:0.08:0.20), after stirring for 300min, filter, the filter residue enters the potassium sulfate refining process, and adds wet residue 80% by weight of ammonia solution with pH=8.5 was stirred and refined for 30 minutes, filtered and dried to obtain potassium sulfate product.

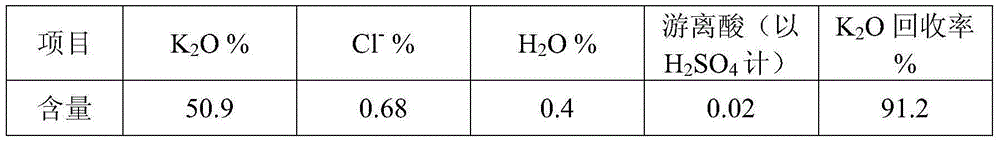

[0044] Table 3.1 is the potassium sulfate product quality data that embodiment 3 produces

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com