Gutta-percha freeze-out device

A technology of eucommia gum and freezing precipitation, applied in the direction of solution crystallization, etc., can solve the problems that plague the industrial production process of eucommia gum, loss of organic solvents, large heat transfer resistance, etc., achieve broad prospects for industrial application, reduce solvent loss, The effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

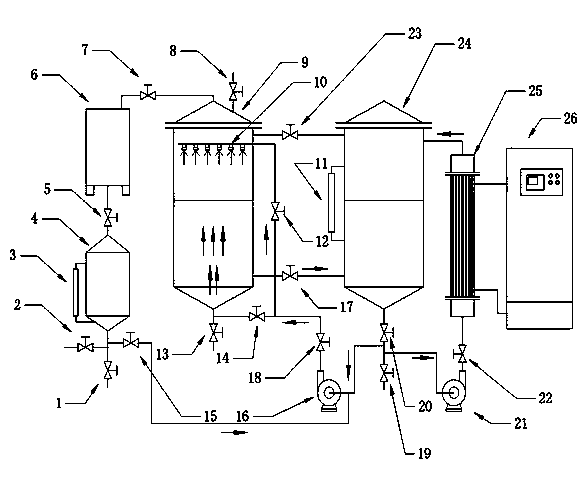

[0016] Now in conjunction with accompanying drawing, the present invention is described in further detail.

[0017] Such as figure 1 The Eucommia jelly freeze-out device shown comprises a freeze-out tank 9 and a water storage tank 24, and the freeze-out tank 9 is provided with a valve 8 for entering the Eucommia glue solution, and a plurality of nozzles 10 are arranged in the freeze-out tank 9, and the freeze-out tank 9 upper end is connected with The upper end of the water storage tank 24, the lower end of the freeze-out tank 9 and the lower end of the water storage tank 24 are respectively connected through the balance valve 23 and the communication valve 17. The communication can make the pressure on the upper part of the two tanks equal, and the water in the lower part of the tank can also be adjusted as needed. Flow; the lower end of the water storage tank 24 forms a water circulation loop through the pump 21, the heat exchanger 25 and the upper end of the water storage t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com