Silicon-based ceramic core with cold and hot impact resistance, high-temperature creep resistance and easy removal performance and preparation process thereof

A technology of anti-cold and thermal shock, ceramic core, used in cores, manufacturing tools, casting and molding equipment, etc., can solve the problem of difficulty in ensuring the uniformity of cristobalite, and achieve excellent easy removal performance, high strength and chemical stability The effect of high temperature and high temperature creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation process of the ceramic core is as follows:

[0035] (1) Quartz glass, alumina and cristobalite are put into a pot mill according to the proportioning ratio, and the pot mill is used at 80r / min for 24 hours, and the obtained powder is used for subsequent use;

[0036] (2) Heat the plasticizer to 85°C, and when it melts completely, add the powder obtained in step (1) into the plasticizer in 4 batches, and the amount of each batch accounts for 25% of the total powder. Stir to ensure that there is no dry powder. After all the powders are added, a slurry is obtained. In the slurry, the ceramic powder accounts for 82%, and the plasticizer accounts for 18%. The composition of the plasticizer is (wt.%): paraffin wax 86%, stearic acid 3%, PVC 11%. The resulting slurry is poured into a slurry ingot for preservation;

[0037] (3) heating the slurry ingot prepared in step (2) to 90-110° C., keeping it warm for 12-24 hours, and preparing a ceramic core blank after ...

Embodiment 1

[0040] Ceramic core composition: quartz glass (100 mesh to 200 mesh): 76%, cristobalite (1000 mesh to 3000 mesh): 4%, alumina (600 mesh to 1000 mesh): 20%; the quartz glass, square The purity of quartz and alumina is 99.9%; after adding plasticizer, press it into a plate-shaped ceramic core blank with a size of 12cm*1cm*0.4cm;

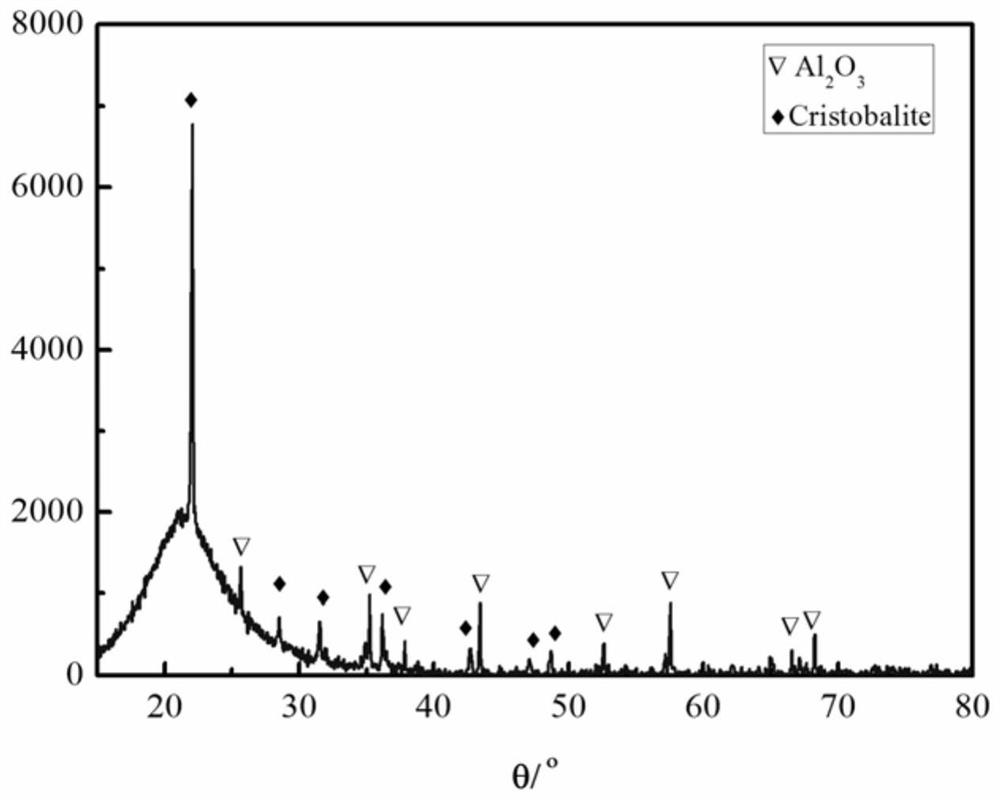

[0041] Use alumina powder with a purity of ≥99.9% and a particle size of 150-200 mesh as a filler, embed the ceramic core blank in the filler powder, raise the temperature to 500°C at a heating rate of 5°C / min and keep it for 5 hours, then heat it at 15°C Raise the temperature to 1220°C at a heating rate of / min, and keep it warm for 2 hours. After sintering the ceramic core, by analyzing the X-ray spectrum, it is calculated that the relative content of cristobalite in the ceramic core is about 10%, and the ceramic core continues to heat up to 1550°C , heat preservation for 1 hour, at this time the high temperature creep performance of the ceramic core...

Embodiment 2

[0045] Ceramic core composition: quartz glass (100 mesh to 200 mesh): 74%, cristobalite (1000 mesh to 3000 mesh): 6%, alumina (600 mesh to 1000 mesh): 20%; the quartz glass, square The purity of quartz and alumina is 99.9%; after adding plasticizer, press it into a plate-shaped ceramic core blank with a size of 12cm*1cm*0.4cm;

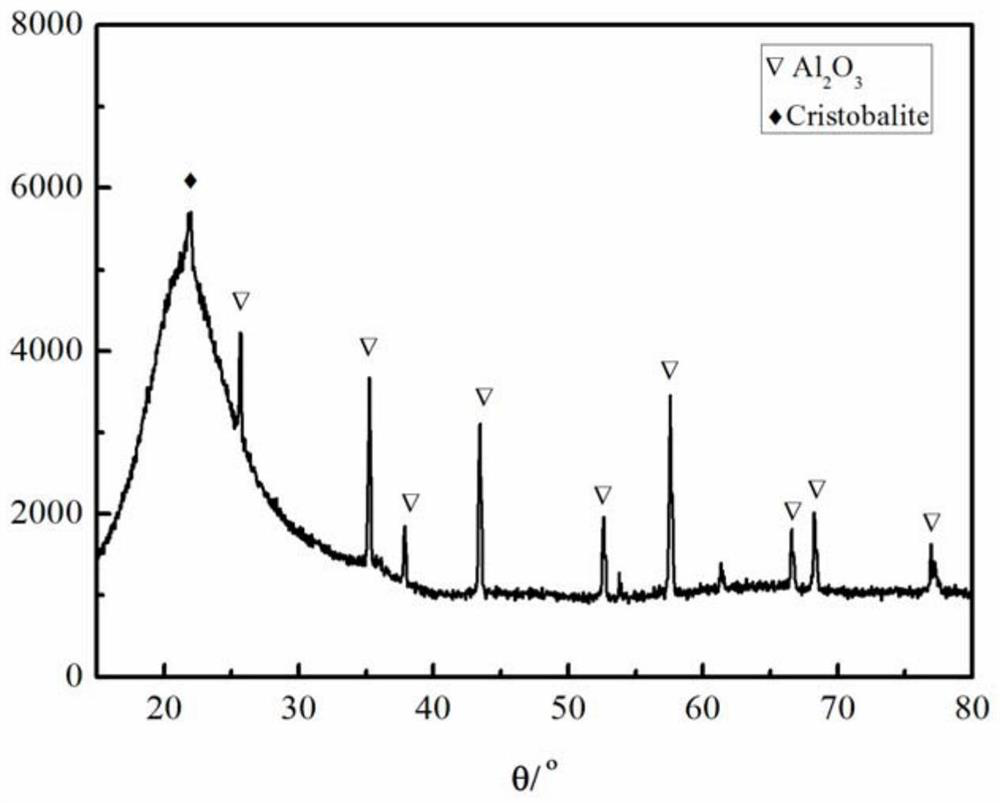

[0046]Use alumina powder with a purity of ≥99.9% and a particle size of 150-200 mesh as a filler, embed the ceramic core blank in the filler powder, raise the temperature to 500°C at a heating rate of 5°C / min and keep it for 5 hours, then heat it at 15°C Raise the temperature to 1220°C at a heating rate of / min, and keep it warm for 2 hours. After sintering the ceramic core, by analyzing the X-ray spectrum, calculate that the relative content of cristobalite in the ceramic core is about 15%, and continue to heat the ceramic core to 1550°C , heat preservation for 1 hour, at this time the high temperature creep performance of the ceramic core was measure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com