Method for producing optical laminate

A technology for optical laminates and manufacturing methods, which is applied to chemical instruments and methods, optics, optical components, etc., can solve the problems of reduced transparency of thermoplastic resin substrates, and achieve full crystallization and high-efficiency crystallization effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0104] As the thermoplastic resin substrate, amorphous polyethylene terephthalate (IPA-copolymerized PET) having a thickness of 100 μm, a crystallization index of 0 to 0.1, and 5 mol % of isophthalic acid units having a Tg of 75° C. was copolymerized was used. Corona treatment (58W / m 2 / min). Prepare acetoacetyl-modified PVA (manufactured by Nippon Synthetic Chemical Industry Co., Ltd., trade name: GOHSEFIMER Z200) at a ratio of 1:9, average polymerization degree: 1200, saponification degree: 98.5 mol% or more, acetoacetylation degree: 5 %) and PVA (average degree of polymerization: 4200, saponification degree: 99.2 mole %) PVA-based resin, and relative to this PVA-based resin of 100 parts by weight, add 13 parts by weight of potassium iodide, prepared PVA-based resin aqueous solution (PVA Resin-like concentration: 5.5% by weight). This aqueous solution was applied to the corona-treated surface of the resin substrate so that the film thickness after drying was 13 μm, and dri...

Embodiment 2

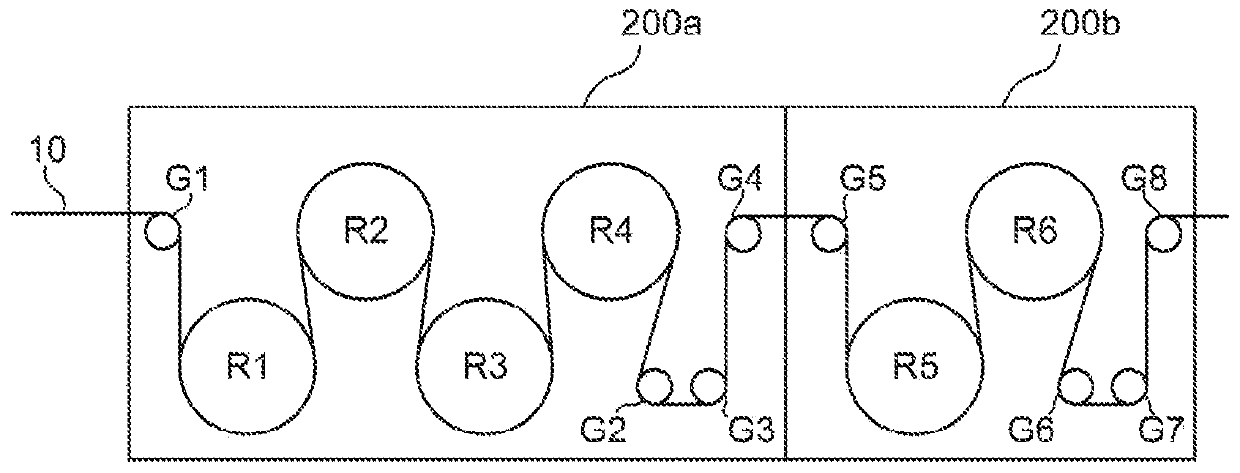

[0114] Turn off the temperature adjustment of the first roller R1 from the upstream side, set the temperature of the rollers R2 to R4 to 90°C, and set the contact time between the laminate and the heating rollers R2 to R4 to 3 seconds (total: 9 seconds minutes), the contact time with the heating rollers R5 to R6 is set to 3 seconds (total: 6 seconds), and the hot air is sent in such a way that the atmosphere temperature in the second crystallization treatment oven becomes 100°C. An optical laminate was produced in the same manner as in Example 1 except the above.

Embodiment 3

[0116] The temperature of R5 was set to 105°C, and the hot air was blown so that the atmospheric temperature in the first crystallization oven was 95°C, and the atmosphere temperature in the second crystallization oven was 95°C. The optical laminated body was produced similarly to Example 1 except having blown hot air at 100 degreeC.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com