Method for preparing food grade potassium dihydrogen phosphate by using industrial wet-process purified phosphoric acid

A technology of potassium dihydrogen phosphate and wet purification, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., to achieve high purity, improved purity, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

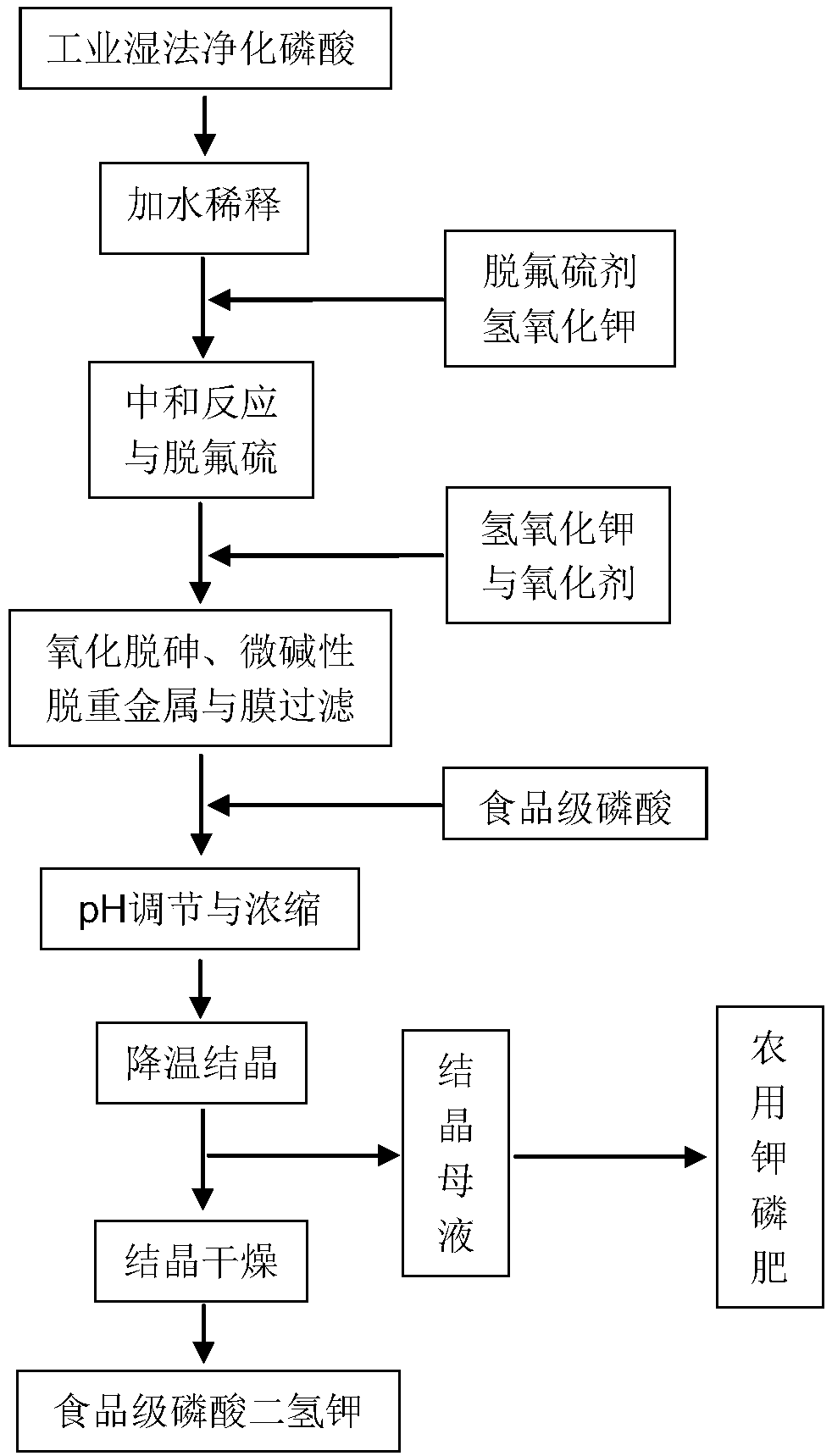

Image

Examples

Embodiment 1

[0035] A kind of method utilizing industrial wet purification phosphoric acid to manufacture food-grade potassium dihydrogen phosphate, its steps are:

[0036] (1) Add water to dilute and take qualified products conforming to HG / T4069-2008 "Industrial Wet Purification of Phosphoric Acid" and industrial wet purification phosphoric acid with a mass percentage concentration of 85% in an acid-resistant container. The reverse osmosis pure water with a multiple of 1.12 times was continuously stirred for 0.5 hour to obtain an industrial wet purification phosphoric acid dilution solution with a concentration of 40% by mass. During the whole process of controlling this step, the stirring speed is 100 rpm.

[0037] (2) Neutralization reaction and sulfur removal step (1) Put 1.5 kg of industrial wet purification phosphoric acid diluent with 40% concentration in mass percent into an acid-resistant container, and add barium carbonate with a mass fraction of 0.2% in the condition of constan...

Embodiment 2

[0044] A kind of method utilizing industrial wet purification phosphoric acid to manufacture food-grade potassium dihydrogen phosphate, its steps are:

[0045] (1) Add water to dilute and take the qualified products that meet the requirements of HG / T 4069-2008 "Industrial Wet Purification of Phosphoric Acid" and the industrial wet purification phosphoric acid with a mass percentage concentration of 85% in an acid-resistant container. The reverse osmosis pure water with a mass multiple of 0.98 times was stirred for 1.0 hour to obtain an industrial wet purification phosphoric acid dilution with a mass percent concentration of 43%. During the whole process of controlling this step, the stirring speed is 100 rpm.

[0046] (2) Neutralization reaction and sulfur removal step (1) Take 9.83 kg of industrial wet-purified phosphoric acid dilution solution with a mass percentage concentration of 43% in an acid-resistant container, and add 0.3% of its mass fraction of carbonic acid under ...

Embodiment 3

[0053] A kind of method utilizing industrial wet purification phosphoric acid to manufacture food-grade potassium dihydrogen phosphate, its steps are:

[0054] (1) Add water to dilute and take the qualified products that meet the requirements of HG / T 4069-2008 "Industrial Wet Purification of Phosphoric Acid" and the industrial wet purification phosphoric acid with a mass percentage concentration of 85% in an acid-resistant container. The reverse osmosis pure water with a mass multiple of 1.30 times was continuously stirred for 0.5 hour to obtain an industrial wet purification phosphoric acid dilution solution with a mass percentage concentration of 37%. During the whole process of controlling this step, the stirring speed is 100 rpm.

[0055] (2) Neutralization reaction and sulfur removal step (1) 3.5 kg of industrial wet purification phosphoric acid diluent with a mass percentage concentration of 37% is placed in an acid-resistant container, and barium carbonate with a mass f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com