Method for extracting aluminum potassium product from associated alum quarry tailings

A technology of ore tailings and alunite, applied in the field of resources, can solve the problem of less development and utilization of associated alunite ore tailings, achieve preliminary separation and improve the effect of leaching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

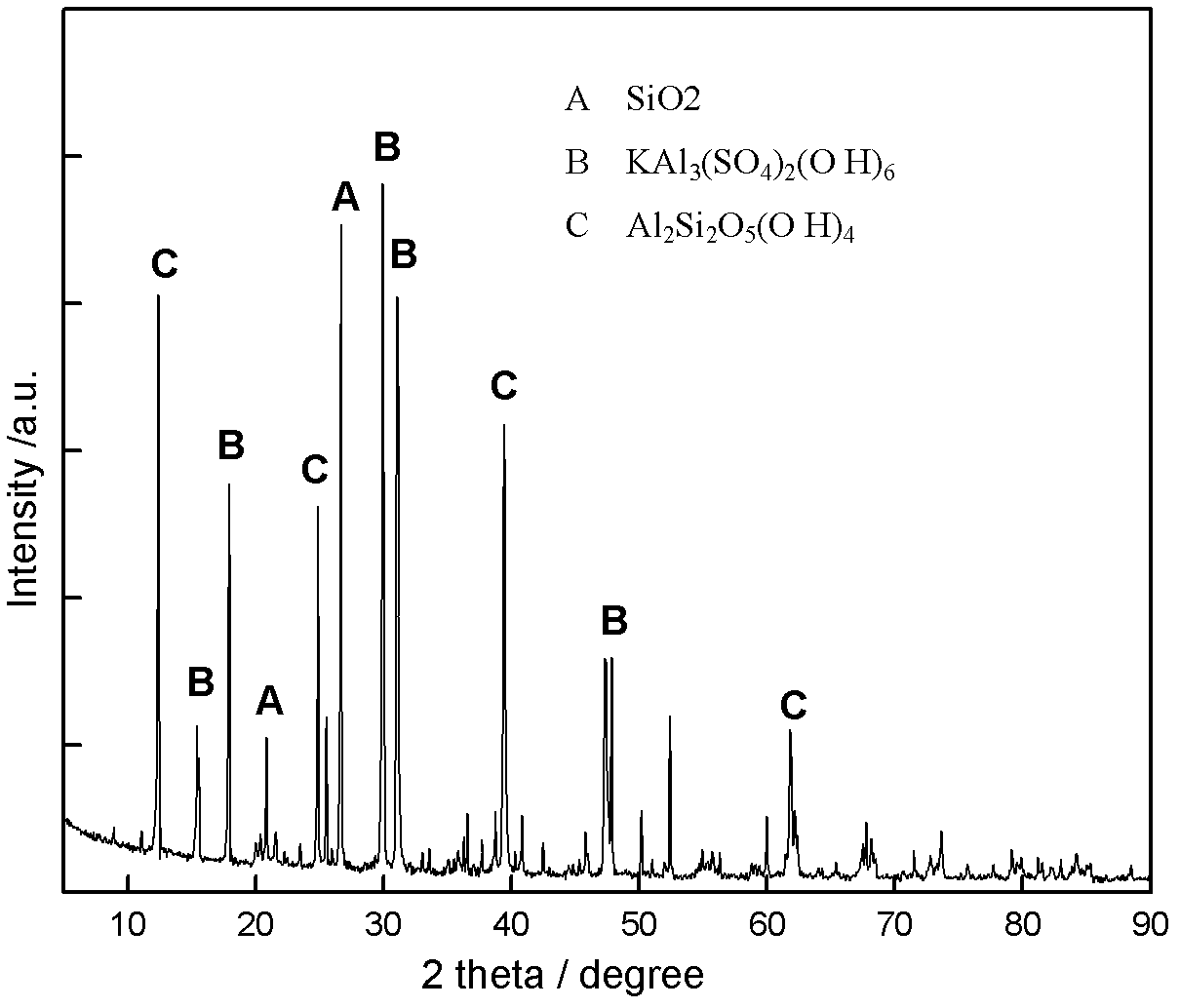

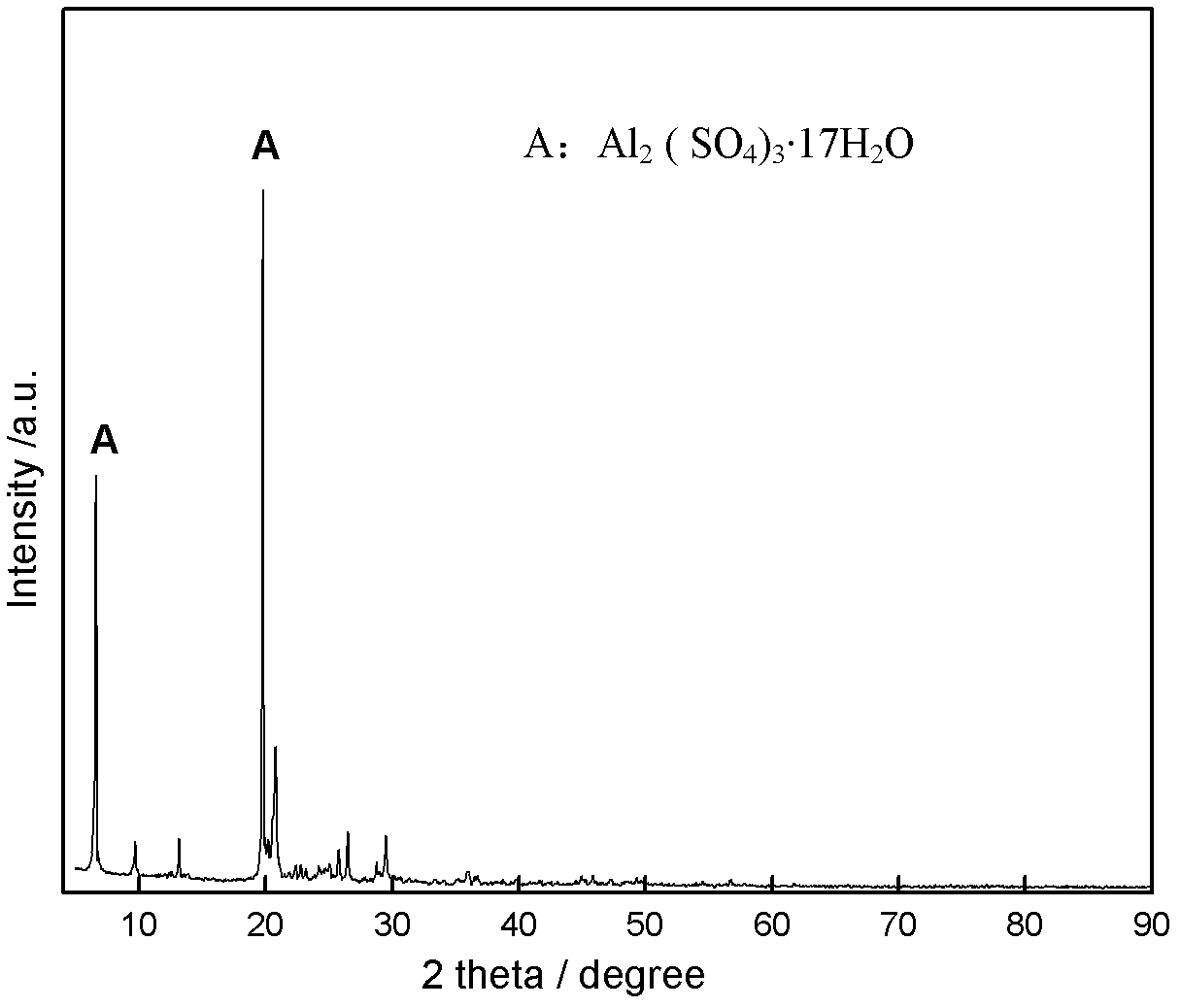

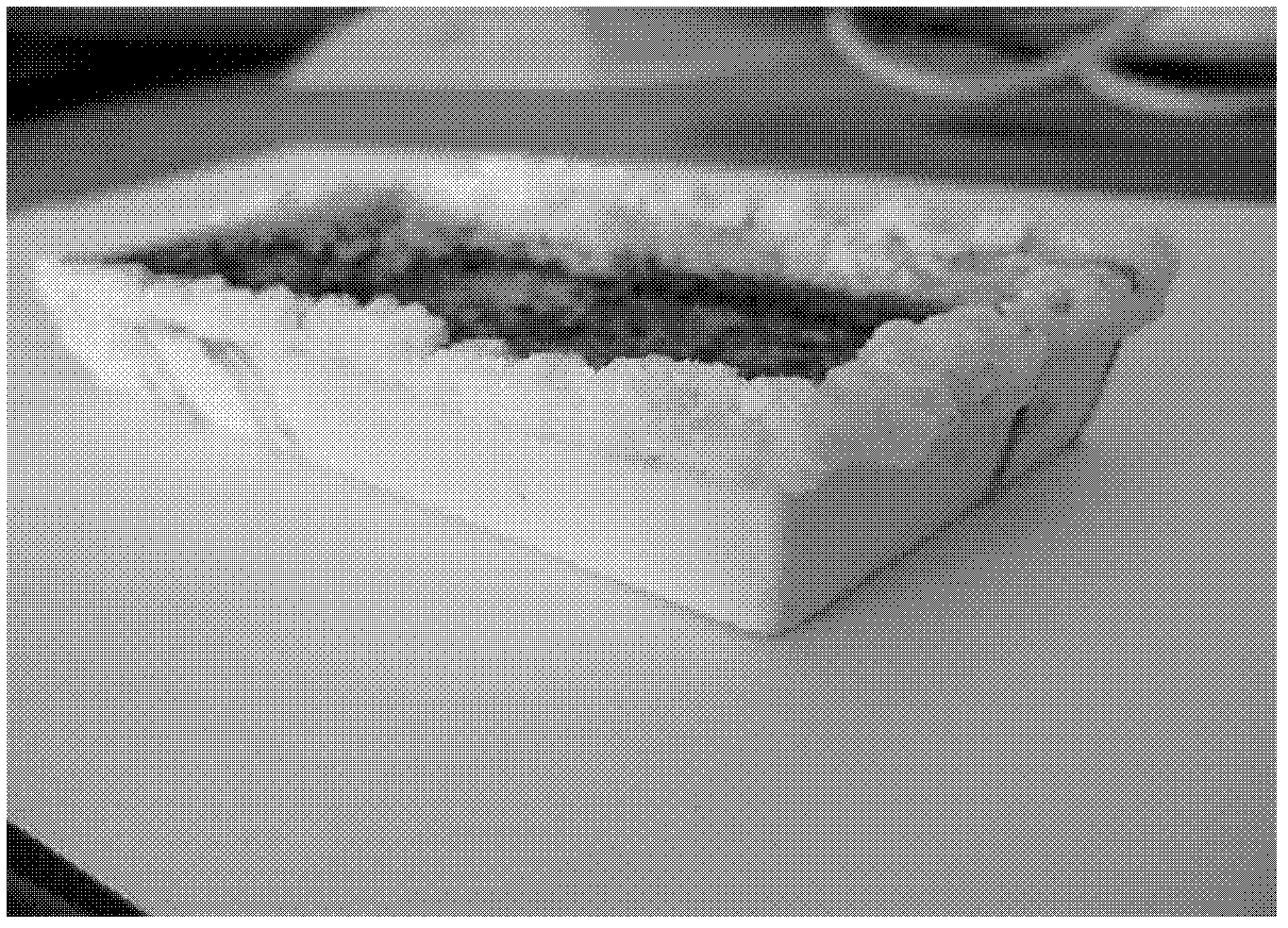

[0028] The associated alunite tailings were mixed with 20% sulfuric acid solution at a liquid-to-solid ratio of 2:1, and put into a muffle furnace for roasting at 300°C for 3 hours. After taking it out and cooling it down to room temperature naturally, add the deionized water required for the liquid-solid ratio of 1:1 with the ore sample before roasting, and let it stand for crystallization for 36 hours. The obtained crystal (its XRD spectrogram, physical photo and XRF analysis results are shown in figure 2 , image 3 and Table 1) After collection, the remaining slag was mixed with deionized water at a liquid-solid ratio of 8:1, stirred in a water bath at 90°C for 3 hours, and filtered. Pour the filtrate obtained after the acid melting-water immersion treatment into the crystallizer, let it stand for crystallization at room temperature for 24 hours, and take out the crystal (the XRD spectrum, physical photo and XRF analysis results are respectively shown in Figure 4 , Fi...

Embodiment 2

[0030] With example 1, change 20% sulfuric acid solution into 30% sulfuric acid solution, also can obtain three kinds of crystals similar to embodiment 1 in three steps. At the same time, the leaching rates of Al and K were slightly increased.

Embodiment 3

[0032] Same as Example 1, the acid melt roasting temperature is reduced from 300 DEG C to 280 DEG C, compared with Embodiment 1, the first crystallization weight reduces by 10%, and there is no significant difference in the second and third crystallization weights. At the same time, the leaching rate of Al remains unchanged, while the leaching rate of K decreases slightly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com