Process for preparing compound catalytic material of nanometer molecular sieve and silica-sesquioxide

A technology of composite catalytic materials and nano-molecular sieves, which is applied in the direction of molecular sieve catalysts, physical/chemical process catalysts, and nano-structure manufacturing. It can solve the problems of nano-molecular sieve structure damage, large nano-molecular sieve particles, and long preparation time. Effects of improving catalytic performance and simplifying operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

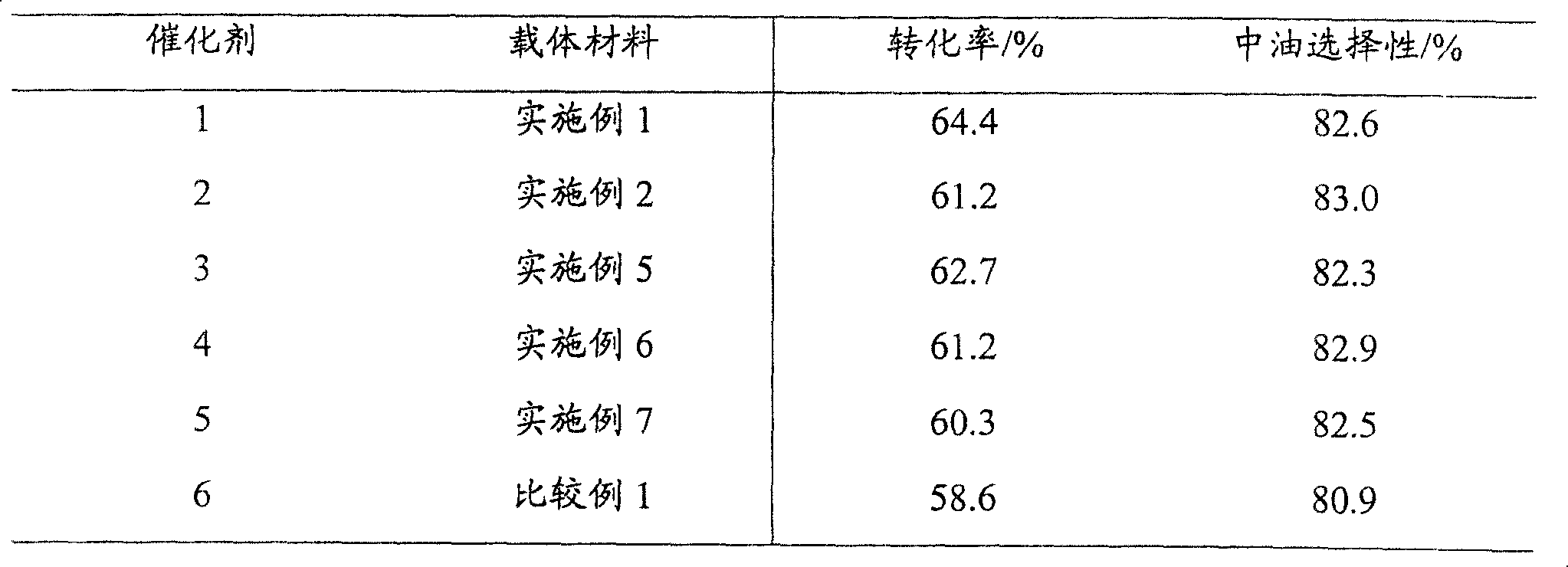

Examples

Embodiment 1

[0026] Example 1: Preparation method of nanometer Y-type molecular sieve / amorphous silicon-aluminum composite material.

[0027] Nano Y-type molecular sieves were prepared by directing agent method.

[0028] Directing agent preparation: use water glass as the silicon source and sodium metaaluminate as the aluminum source. Mix 150ml of water glass (modulus 3.0) with 200ml of water to obtain solution A; add 9.5g of sodium metaaluminate and 40g of sodium hydroxide to 200ml of water until completely dissolved to obtain solution B; Stir at ~20°C for 1 hour to prepare the molar ratio: 9Na 2 O:Al 2 o 3 : 8SiO 2 : 100H 2 A directing agent for O, aged for 6-48 hours for later use.

[0029] Preparation of nano Y-type molecular sieve: Dissolve 32g of sodium metaaluminate and 5g of sodium hydroxide in 400ml of water to obtain solution C; mix 300ml of water glass with 300ml, then add 50ml of Tween-20 to obtain solution D. Pour solution D into solution C to obtain sol E, and stir E a...

Embodiment 2

[0033] The preparation of the directing agent is the same as in Example 1.

[0034] The preparation of the nanometer Y-type molecular sieve is the same as in Example 1, except that the power of the microwave treatment is 600 W and the treatment time is 15 minutes to obtain the nanometer Y-type molecular sieve.

[0035] Transfer the Y-type molecular sieve containing mother liquor obtained above to a 500ml plastic beaker, add 144g sodium metaaluminate, and at 50°C, adjust the pH value of the system to 8.0 with hydrochloric acid to form a gel. Then filter, wash, Dry at 120° C. for 12 hours, and calcined at 500° C. for 4 hours to obtain a Y / ASA composite catalytic material, wherein the content of Y molecular sieve is 30 wt %. According to the XRD test, the SiO of Y molecular sieve 2 / Al 2 o 3 The ratio is 4.85, the unit cell constant a 0 It is 2.4735, the relative crystallinity is 36.8%, and the silicon-aluminum molar ratio of silicon-aluminum oxide is 1.1:1.

[0036] After A...

Embodiment 3

[0038] The preparation of the directing agent is the same as in Example 1.

[0039] The preparation of the nanometer Y-type molecular sieve is the same as in Example 1, except that the power of microwave treatment is 400W and the treatment time is 25 minutes to obtain the nanometer Y-type molecular sieve.

[0040] Transfer the Y-type molecular sieve containing mother liquor obtained above to a 500ml plastic beaker, add 72g of sodium metaaluminate, and at 50°C, adjust the pH of the system to 8.5 with sulfuric acid to form a gel. Then filter, wash, Dry at 120° C. for 12 hours, and calcined at 500° C. for 4 hours to obtain a Y / ASA composite catalytic material, wherein the content of Y molecular sieve is 15 wt%. According to the XRD test, the SiO of Y molecular sieve 2 / Al 2 o 3 The ratio is 4.85, the unit cell constant a 0 It is 2.4735, the relative crystallinity is 28.2%, and the silicon-aluminum molar ratio of silicon-aluminum oxide is 2.1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com