Glaze and method for forming glaze layer

A glaze layer and glaze technology, applied in the field of building materials and decoration materials, can solve the problems of limited natural rock mass, unsuitable for decoration, limited application of natural stone, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

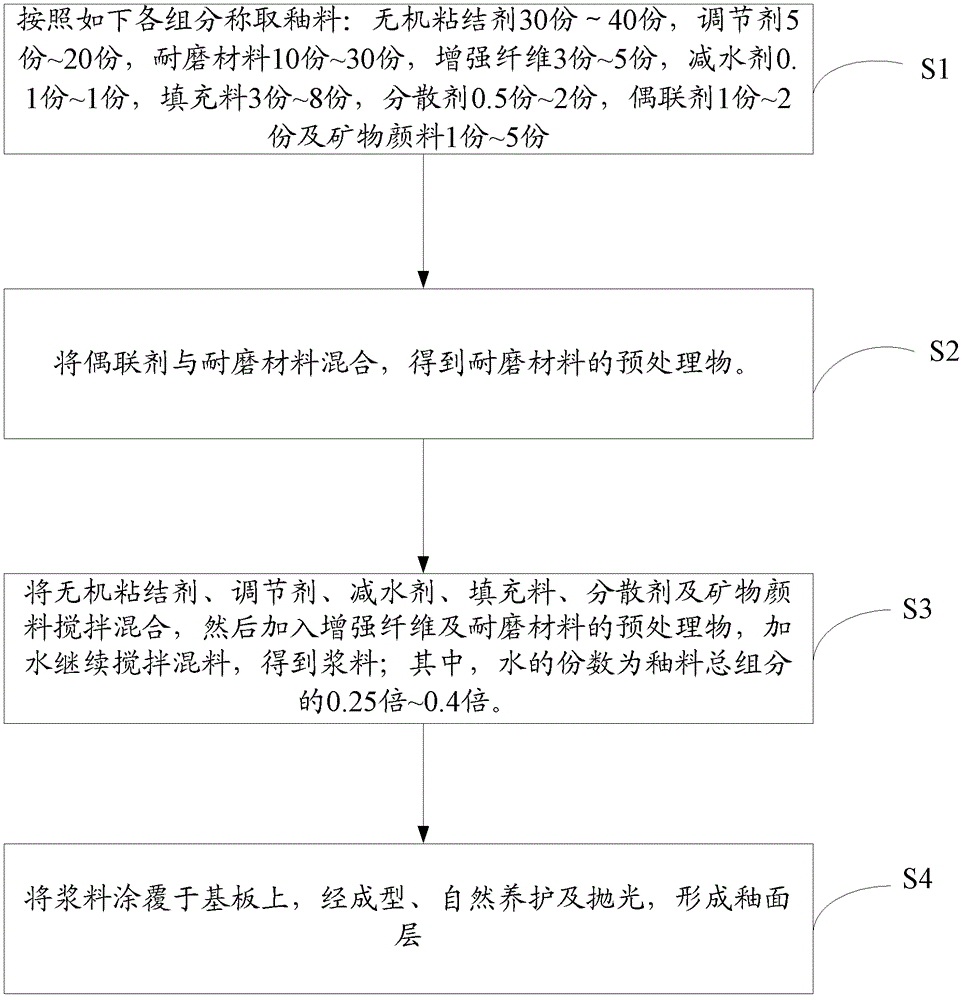

Method used

Image

Examples

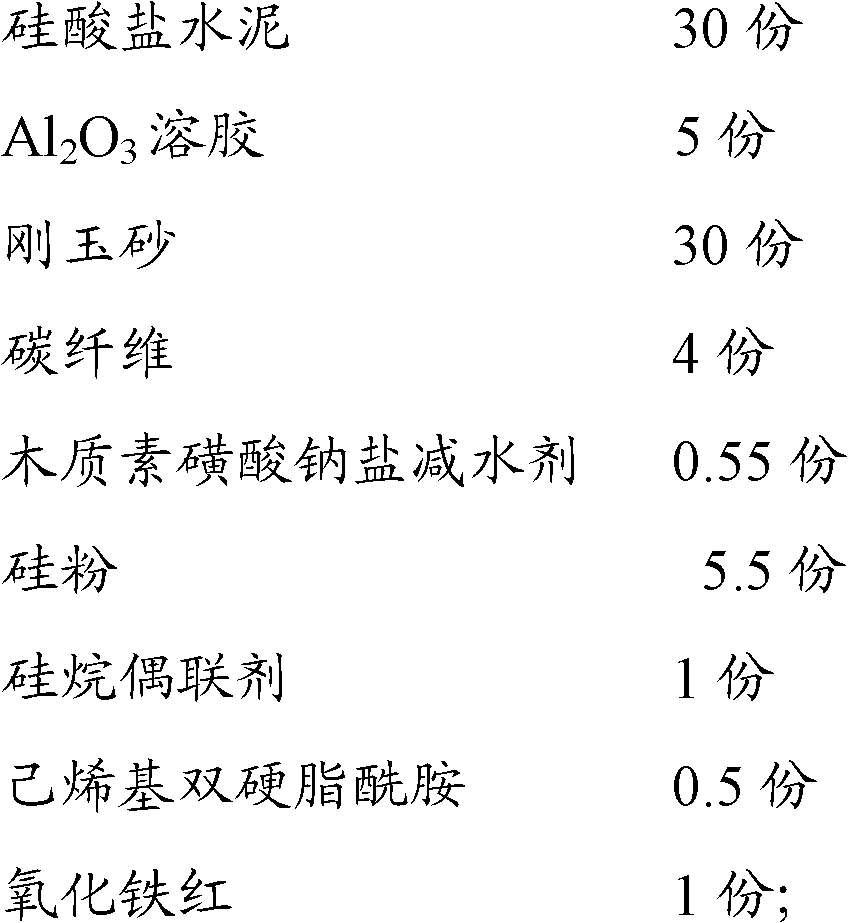

Embodiment 1

[0043] Glaze:

[0044]

[0045] Weigh each component, first mix and stir the silane coupling agent and corundum sand for 10 minutes to obtain the pretreated product of corundum sand; then, mix Portland cement, Al 2 o 3 Sol, lignosulfonic acid sodium salt superplasticizer, silicon powder, hexenyl bisstearamide and iron oxide red were stirred and mixed for 5 minutes, then added carbon fiber and corundum sand pretreatment, adding 0.25 times the total glaze composition Using a mixer to stir the mixture for 5 minutes to obtain a slurry; apply the slurry to a cement fiber board, shape it with a vibrating compressor, and after the surface is polished and initially set, the mold will be removed after 24 hours of natural curing at room temperature , and then continue the natural curing for 120 hours, and finally use a polishing machine to polish the surface of the glaze layer to form a glaze layer on the cement fiber board. The glaze layer of this embodiment is red, soft in color,...

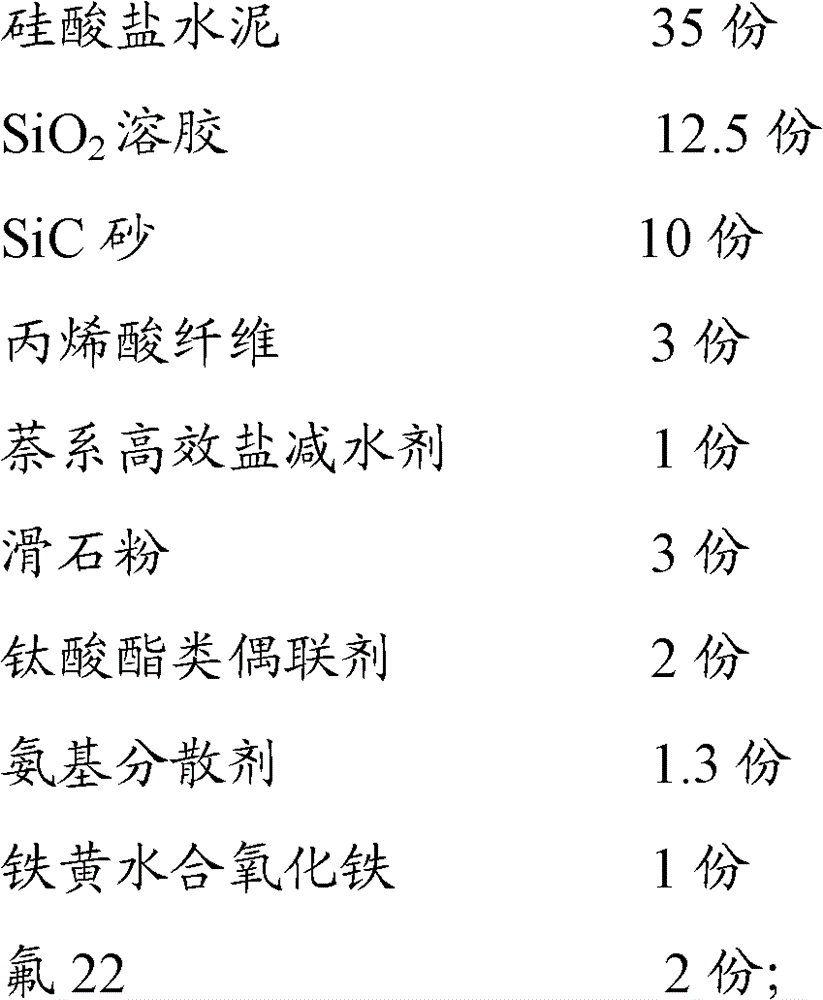

Embodiment 2

[0047] Glaze:

[0048]

[0049] Weigh each component, first mix and stir the titanate coupling agent and SiC sand for 20 minutes to obtain the pretreated product of SiC sand; then, mix Portland cement, SiO 2 Sol, naphthalene series high-efficiency salt superplasticizer, talc powder, amino dispersant (model: CM86, Banger Trading Co., Ltd., Shunde District, Foshan City), iron yellow hydrated iron oxide and fluorine 22 and stir and mix for 8 minutes, then add acrylic fiber and SiC Sand pretreatment, add 0.3 times of water to the total composition of the glaze, use a mixer to mix the mixture for 8 minutes to obtain a slurry; apply the slurry on a concrete slab, and use a vibrating compressor to form, the surface is smooth and initial After coagulation, remove the mold after natural curing at room temperature for 36 hours, and then continue natural curing for 100 hours. Finally, use a polishing machine to polish the surface of the glazed layer to form a glazed layer on the concr...

Embodiment 3

[0051] Glaze:

[0052]

[0053]

[0054] Weigh each group, mix and stir the aluminate coupling agent and quartz sand for 30 minutes to obtain the pretreated product of quartz sand; then, mix Portland cement, ZrO 2 Sol, aliphatic superplasticizer, calcium carbonate powder, monoglyceride stearate, amino dispersant (model: CM86, Banger Trading Co., Ltd., Shunde District, Foshan City), carbon black and fluorine 22 were stirred and mixed for 10 minutes, and then added The pretreated product of PVA fiber and quartz sand is added with water 0.35 times the total composition of the glaze, mixed with a mixer for 10 minutes to obtain a slurry; the slurry is coated on a silicon-calcium board, and formed by a vibrating compressor , after the surface is polished and initially set, the mold is removed after natural curing at room temperature for 24 hours, and then the natural curing is continued for 120 hours. Finally, the surface of the glaze layer is polished by a polishing machine t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com