Method for producing food grade potassium chloride

A production method and technology of potassium chloride, applied in the field of production technology of food-grade potassium chloride, can solve the problems of inconvenient production and use, wide particle size distribution, easy hardening, etc., and achieve high production efficiency, reduced production process, and low content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

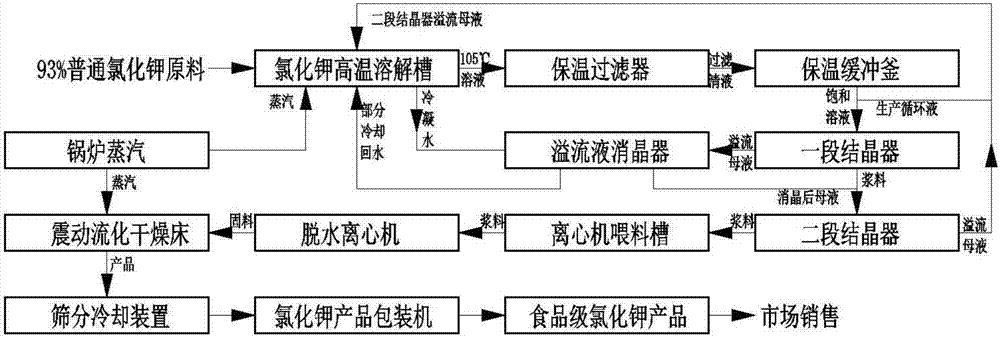

[0025] see attached figure 1 , the process of two-stage continuous crystallization of food-grade potassium chloride of the present invention mainly includes processes such as high-temperature dissolution, filtration and purification, continuous crystallization, dehydration separation, and drying, which are implemented in the following steps:

[0026] High-temperature dissolution process: put 95-115Kg of 93% potassium chloride raw material into 1m 3 In the potassium chloride solution, heat and dissolve under stirring, and prepare a saturated potassium chloride solution at 100-102°C;

[0027] Filtration and purification process: when the temperature of the solution rises to 103-105°C, filter the solution while it is hot to obtain a clear hot saturated solution of potassium chloride, which is stored in a buffer tank with heat preservation function for later use;

[0028] Continuous crystallization process: continuously pump hot saturated potassium chloride solution into the cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com