Gasification and high-temperature tar removal and dust removal integrated technology of biomass circulating fluidized bed

A circulating fluidized bed, biomass technology, applied in gasification process, petroleum industry, manufacture of combustible gas, etc., can solve the problems of large processing scale, low energy consumption and high thermal efficiency of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

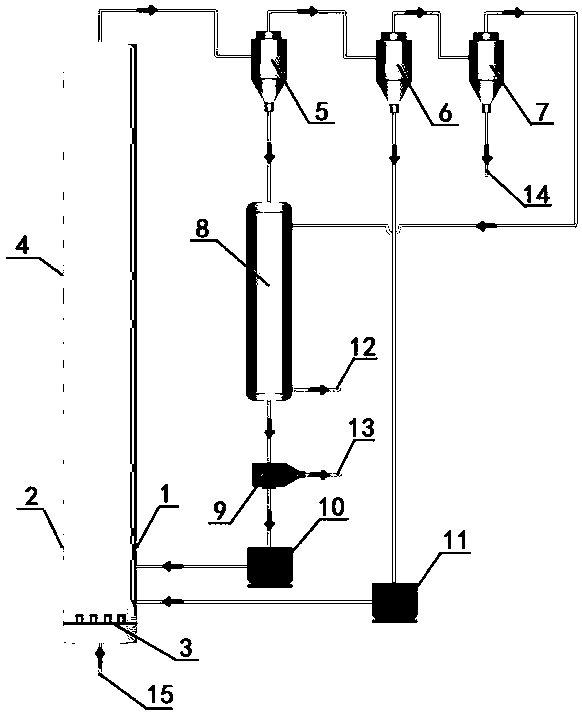

[0014] In an embodiment, the biomass particles and heat carrier less than 5mm are sent into the bottom of the circulating fluidized bed (4) through the biomass particle inlet (1) and the supplementary heat carrier inlet (2) respectively, at 750--900°C. Pyrolysis, combustion and gasification reactions, the residual semi-coke and heat carrier are carried up to the top of the circulating fluidized bed (4) at high speed with the generated gas, and then undergo four-stage gas-solid separation; the first-stage gas-solid separator (5) separates The large particle carrier and semi-coke, as the high-temperature catalytic cracking catalyst of the gas and the filter material for filtering dust, enter the moving bed high-temperature filter (8), and then enter the ultra-fine ash separator (9) to separate the ultra-fine ash and pass through a The first-stage feeder (10) returns to the bottom of the circulating fluidized bed (4) for gasification reaction, and the ultra-fine ash is discharged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com