A kind of gold potassium citrate production technology

A gold potassium citrate, production process technology, applied in the field of gold plating, can solve the problems of easy viscous and hardening of the system, unstable pH, insufficient crystallization, etc., and achieve the effects of stable pH value, improved quality, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

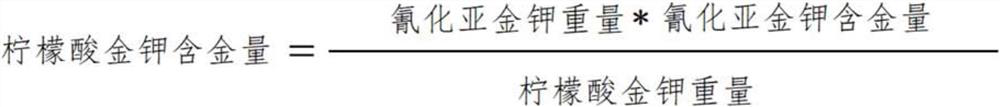

Method used

Image

Examples

Embodiment 1

[0048] 1. Preparation of Potassium Dihydrogen Citrate

[0049] (1) Raw material pulverization: take citric acid and potassium citrate as raw materials, and pulverize the above two kinds of raw materials to 40 mesh respectively, and place them in sealed containers respectively after pulverizing to prevent moisture absorption. Citric acid and citric acid used as raw materials meet the analytical purity standard of national standard reagent grade. (2) Batching: Get the powder of the above two raw materials and carry out batching according to a predetermined ratio, citric acid is 2100g, potassium citrate is 1620g, and the weight ratio of the two is 1.296:1, that is, the molar ratio of the two is 2:1, wherein The calculated weights of citric acid and potassium citrate are water-containing weights. (3) Mixing of raw materials: mix the above two raw materials uniformly immediately after batching according to the above ratio, and the mixing time is 10 minutes. (4) Mixing with water:...

Embodiment 2

[0053] Prepare gold potassium citrate according to the production process of embodiment 1, difference is: the step (5) of preparing potassium dihydrogen citrate carries out in the heating reaction in the mode of steam bath, after experiment steam bath 15 minutes, raw material temperature is at 80 At about ℃, stir and mix with a plastic rod for 5 minutes. Wherein, adding water accounting for 0.5% of the raw material weight during the stirring process makes the material soften and facilitate stirring. Other processing steps are all identical with embodiment 1.

[0054] In step 1, 3398 g of potassium dihydrogen citrate was finally obtained, with a yield of 98.5% and a purity of 99%. In the step 2, 4239g of gold potassium citrate is finally obtained, the yield is 99.5%, the gold content is 46.6%, and the pH value of the product is 3.5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com