Continuous flow aerobic granular sludge reaction device provided with stirring paddle internal components and method

An aerobic granular sludge and reaction device technology, which is applied in the methods of granulating raw materials, sludge treatment, biological treatment devices, etc., can solve the problems of hydraulic shear force disorder and uncontrollable hydraulic scouring, and achieve effective treatment , Good working performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

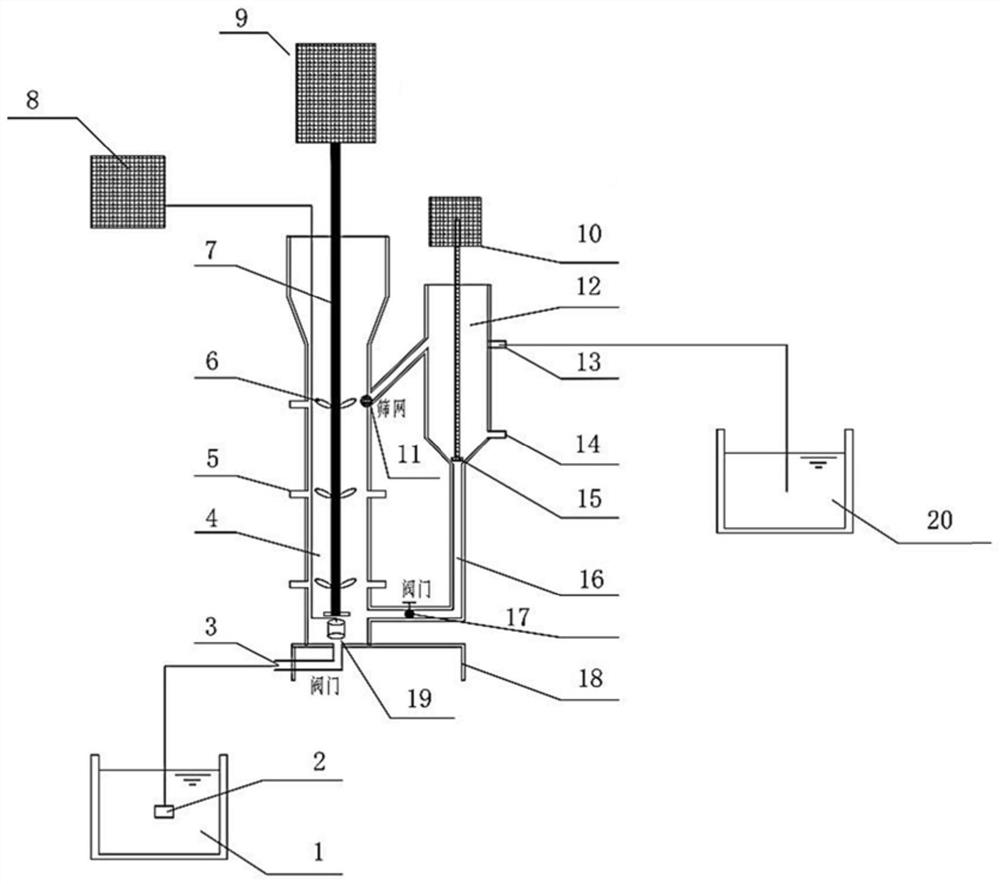

[0040] In this embodiment, the structure of the continuous flow aerobic granular sludge reaction device adopted is as above, and will not be repeated here. The specific parameters involved are as follows: the aerobic bioreactor 4 adopts a cylindrical hollow plexiglass cylinder with an effective volume of 3L, an effective height of 50cm in the cylinder, an inner diameter of 10cm, and a height-to-diameter ratio of 5:1; the precipitation reactor 12 The effective volume is 1L, the upper part is cylindrical, the lower part is tapered conical shape, the effective height is 20cm, the inner diameter is 10cm, and the cone height is 5cm. The inoculated sludge was taken from the return sludge of a domestic sewage treatment plant, and the concentration of the inoculated sludge was 4000 mg / L; the organic wastewater was prepared urban domestic sewage.

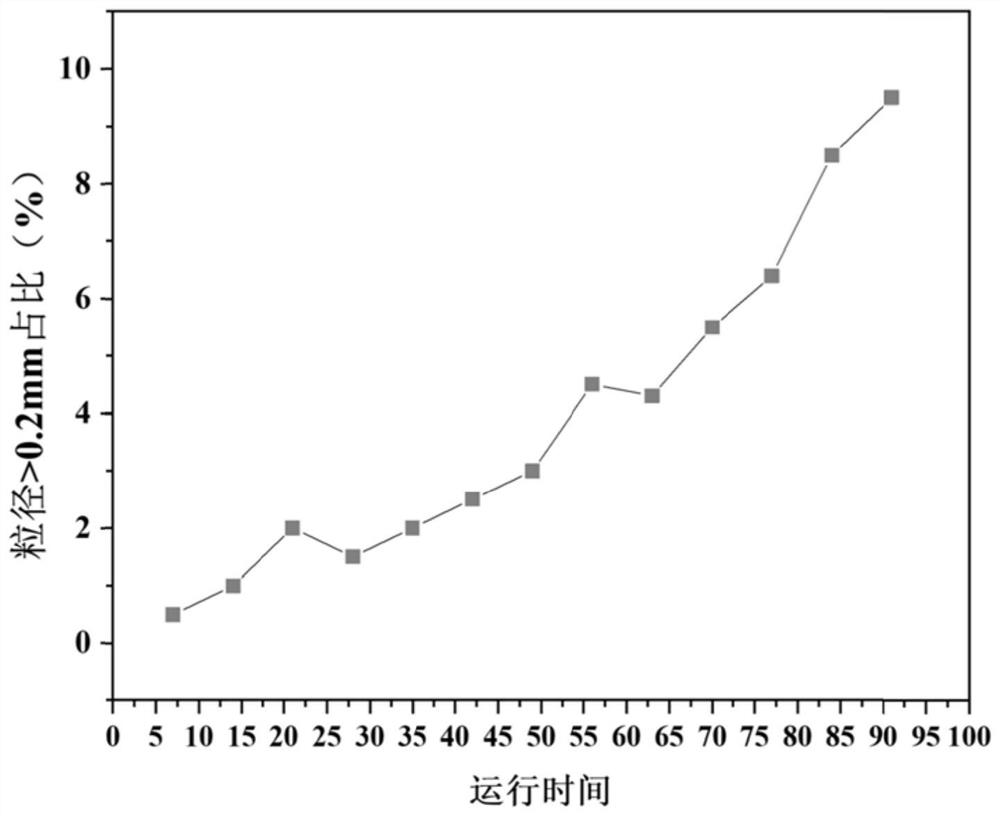

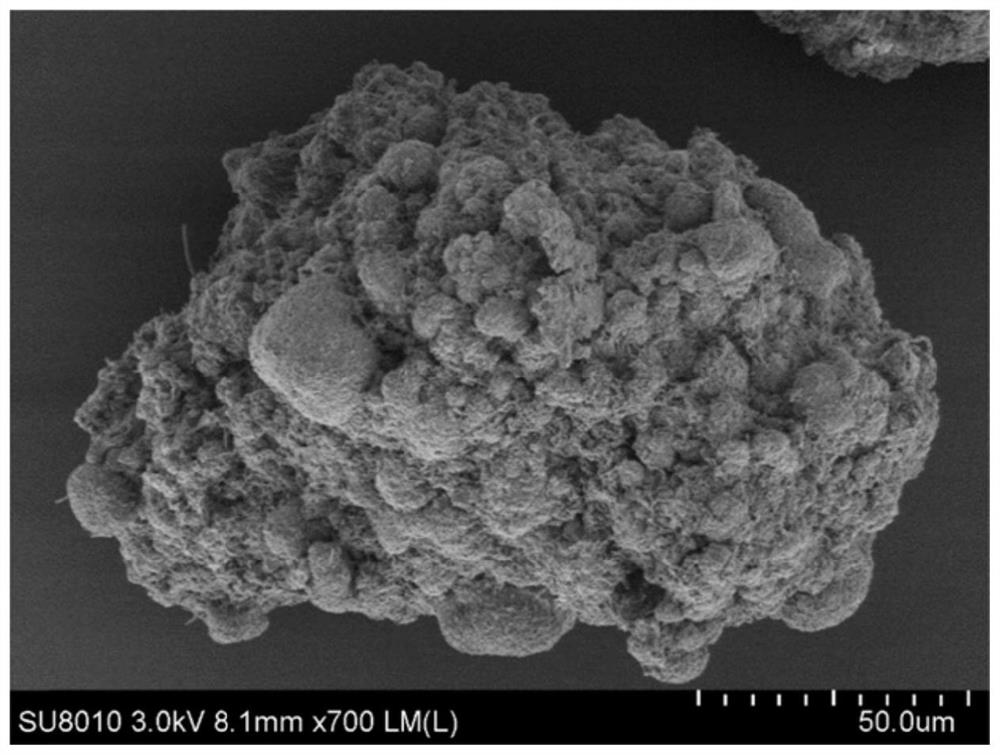

[0041] The operation process of using the above-mentioned continuous flow aerobic granular sludge reactor to treat urban sewage and cultiva...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com