Treatment method for blast furnace melting slag

A processing method and slag melting technology, which is applied in the field of blast furnace slag processing, can solve the problems of inability to process liquid blast furnace slag, slag glass rate less than 80%, and spiral blade failure, so as to save liquid rotary connection equipment, Ease of maintenance and continuous operation, and the effect of effective waste heat recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A blast furnace slag with an average thermal conductivity of 0.75W / (m·K) is processed.

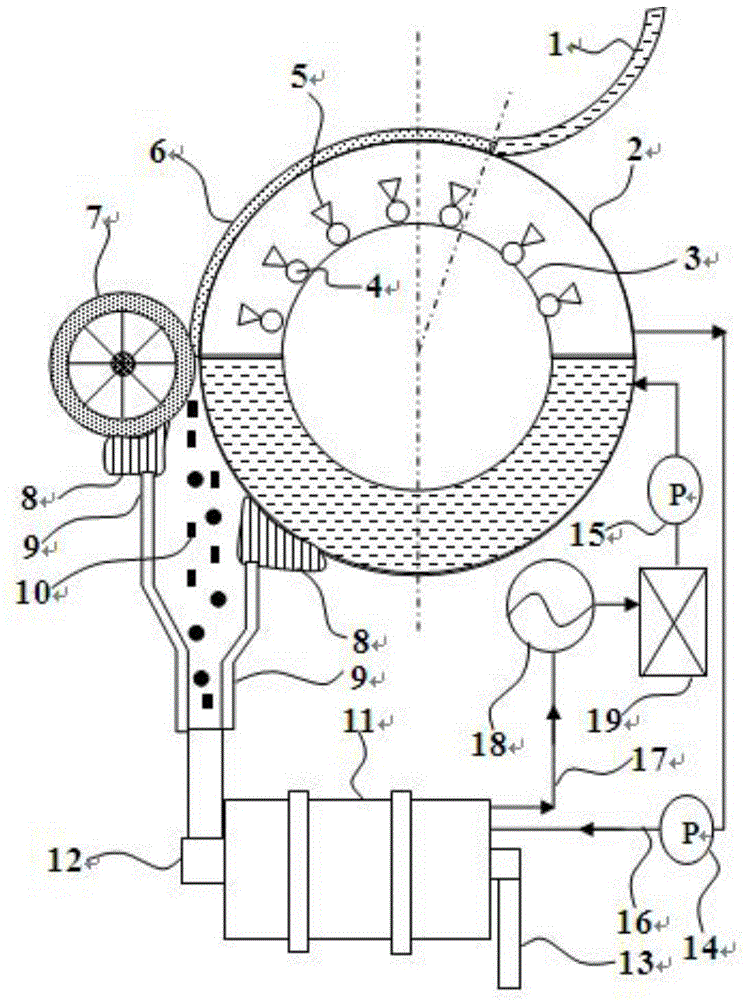

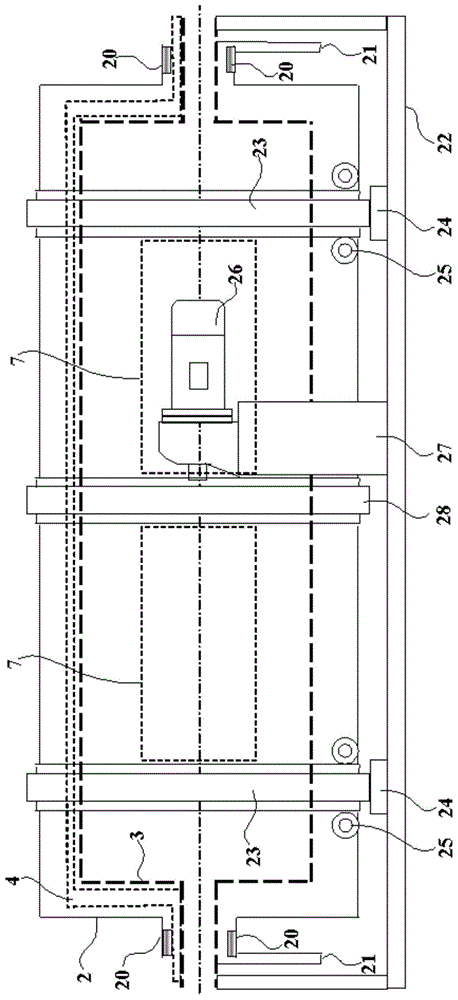

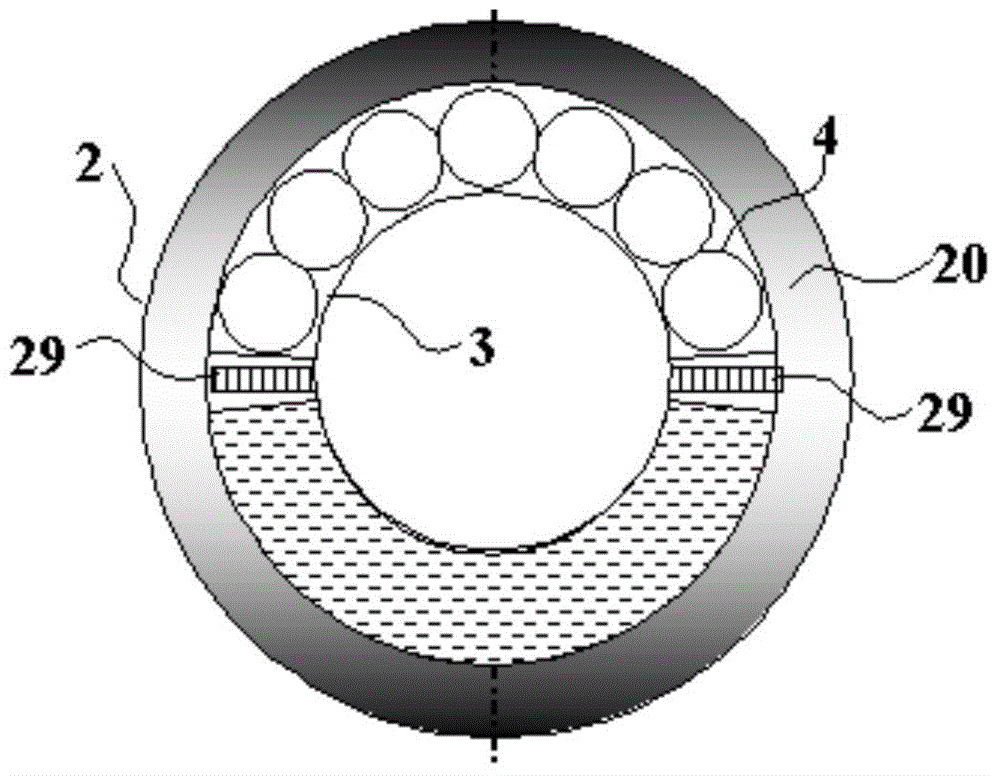

[0049] The outer diameter of the inner-cooled single drum is 1000mm, the thickness is 10mm, and the speed is 3.5 rpm; the outer diameter of the inner-cooled single drum is 300mm, the thickness is 5mm, and the gap between the inner cylinder and the outer cylinder is 350mm; The outer diameter of the drum is 400mm, the wall thickness is 50mm, the speed is 20 rpm, and the outer surface is roughened; a certain type of square water mist nozzle is used, the nozzle aperture is 15mm, the water inlet pressure is 3bar, the spray angle is 60°, and the flow rate is 4.5L / min, the distance between the nozzle opening and the inner surface of the outer cylinder is 250mm, there are 5 cooling water pipes, and each pipe is equipped with 22 nozzles, such as figure 1 As shown, the arrangement is denser on the side of the slag layer to ensure the formation of continuous water mist on the inner surface of ...

Embodiment 2

[0052] A blast furnace slag with an average thermal conductivity of 0.2W / (m·K) is processed.

[0053] The outer diameter of the inner cooling single drum is 3000mm, the thickness is 20mm, and the speed is 1.9 rpm; the outer diameter of the inner cooling single drum is 1400mm, the thickness is 15mm, and the gap between the inner cylinder and the outer cylinder is 800mm; The outer diameter of the drum is 1000mm, the wall thickness is 100mm, the speed is 15 rpm, and the outer surface is engraved with grooves with a width of 0.5mm and a depth of 1mm every 2mm along the axial direction; a certain type of solid rectangular water mist nozzle is used, and the nozzle aperture is 25mm , the water inlet pressure is 1bar, the spray angle is 90° on the long side and 60° on the short side, the flow rate is 5.8L / min, the distance between the nozzle opening and the inner surface of the outer cylinder is 300mm, and there are 8 cooling water pipes arranged at equal intervals. Equipped with 18 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com