A hot film covering device for thin metal sheets and a processing method thereof

A technology of thin metal plates and processing methods, applied in chemical instruments and methods, lamination devices, lamination auxiliary operations, etc., can solve problems such as unsuitable aluminum plate coating, achieve process control, stable operation, and reduce site occupation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

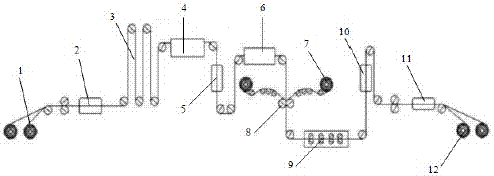

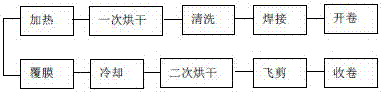

[0037] Such as figure 1 and figure 2 As shown, the metal sheet thermal coating equipment provided by the present invention includes a double uncoiler 1, an automatic welding machine 2, a sewing machine, an uncoiler looper 3, a tension control system, a deviation correction control system, a cleaning and film forming process section, 1 #Drying box 5, heating unit 6, lamination system, cooling unit 9, 2# drying box 10, flying shear equipment 11, double winder 12 and other components. Among them, the uncoiler, automatic welding machine 2, sewing machine, uncoiling looper 3, tension control system, deviation correction control system, flying shear equipment 11, and winder are composed of functions to ensure the smooth operation and conversion of steel strip or aluminum strip, And keep running at the center of the unit, which belongs to general tech...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com