Small plastic part cooling cylinder

A plastic component and small-scale technology, applied in the field of plastic product production, can solve problems such as unsatisfactory, time-consuming, and reduced production efficiency, and achieve the effects of avoiding energy waste, improving cooling efficiency, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

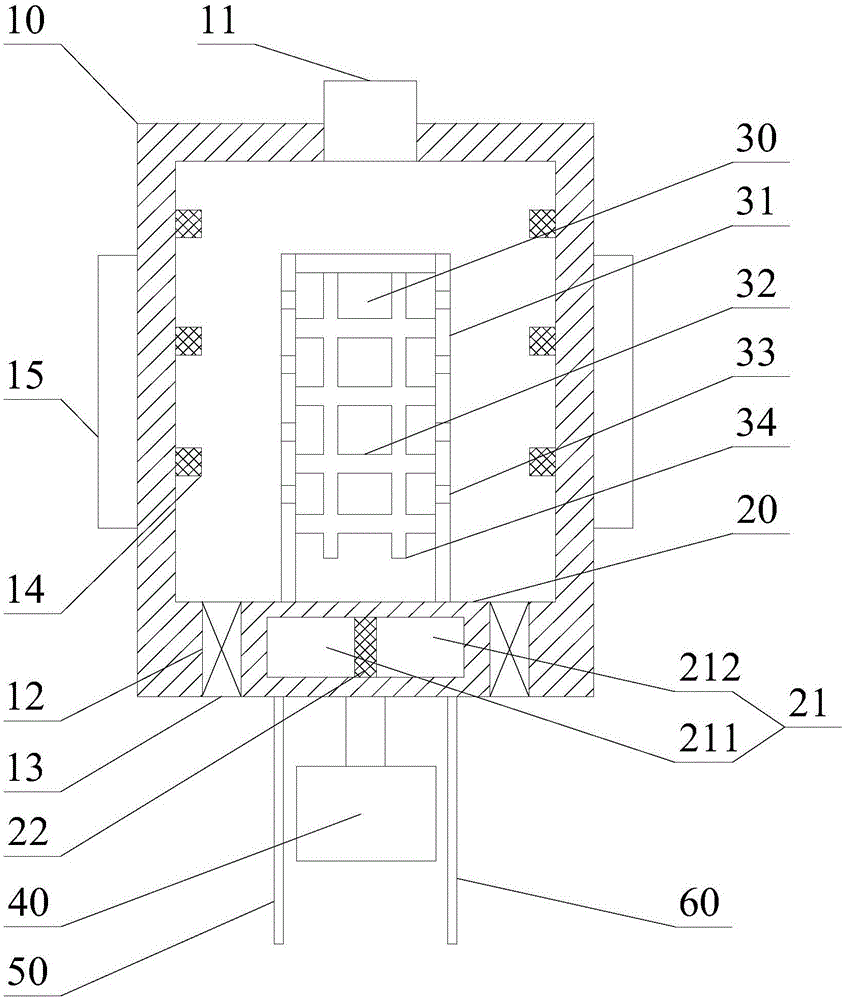

[0035] Such as figure 1 As shown, the cooling cylinder for small plastic parts includes a housing cylinder 10, a rotating disk 20, a cooling net 30, a rotating motor 40, a water inlet hose 50 and a water return hose 60;

[0036] The cooling network 30 includes two vertical water pipes 31 arranged in parallel, and a plurality of horizontal water pipes 32 parallel to the two vertical water pipes; the vertical water pipes 31 are provided with a plurality of on-off valves 33; The on-off valve 33 is located between two adjacent horizontal water pipes 32;

[0037] The top of the containing cylinder 10 is provided with an inlet 11; the bottom of the containing cylinder 10 is provided with a circular through hole 12; the rotating disk 20 is rotatably arranged in the circular through hole 12 through a bearing 13;

[0038] A water collection space 21 is opened in the rotating disk 20; the water inlet hose 50 and the return water hose 60 communicate with the water collecting space 21; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com