Plastic particle cooling device

A technology of cooling device and plastic granules, which is applied in the field of plastic production, can solve the problems of reduced production efficiency, unsatisfactory, and time-consuming problems, and achieve the effects of improving cooling efficiency, making full use of it, and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

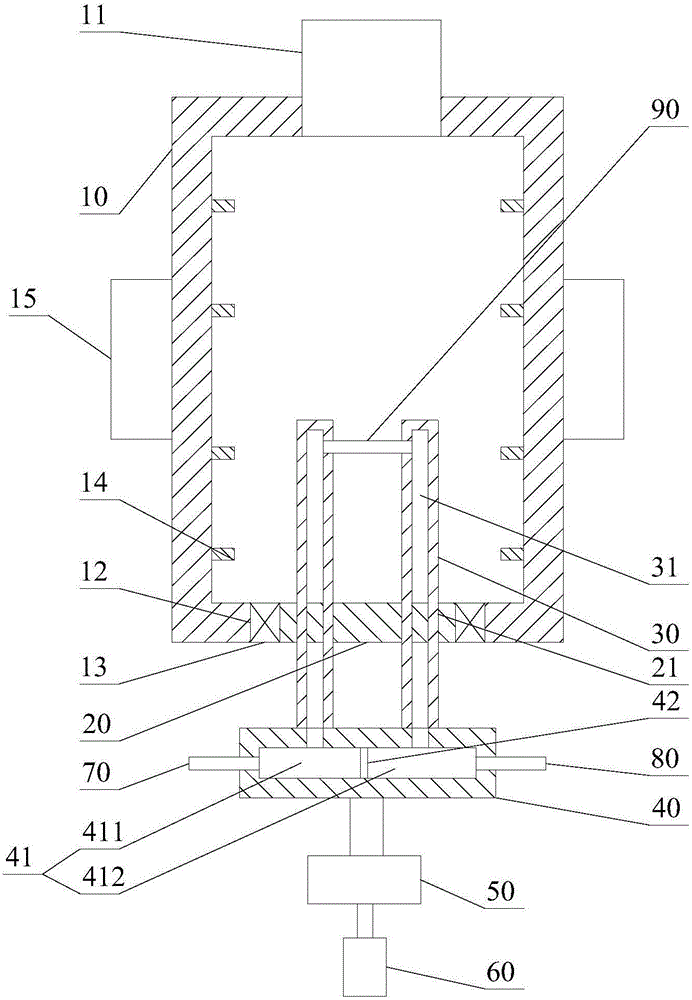

[0033] Such as figure 1 As shown, the cooling device for plastic particles includes a housing cylinder 10, a rotating disk 20, a cooling column 30, a base plate 40, a rotating motor 50, a lifting hydraulic cylinder 60, an inlet hose 70 and a return hose 80;

[0034] The top of the containing cylinder 10 is provided with an inlet 11; the bottom of the containing cylinder 10 is provided with a circular through hole 12; the rotating disk 20 is rotatably arranged in the circular through hole 12 through a bearing 13;

[0035] The rotating disk 20 is provided with a plurality of vertically extending sliding through holes 21; the upper end of the cooling column 30 can slide through the sliding through holes 21 and enter the containing cylinder 10; the lower end of the cooling column 30 Connected to the base plate 40; the cooling column 30 is provided with a cooling water receiving cavity 31; the cooling water receiving cavity 31 is opened on the lower end surface of the cooling colum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com