Adjustable granulation device for modified plastic production and processing

A granulating device and an adjustable technology, which is applied in the field of adjustable granulating devices for the production and processing of modified plastics, can solve the problems of reducing production and processing efficiency, inconvenient operation and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

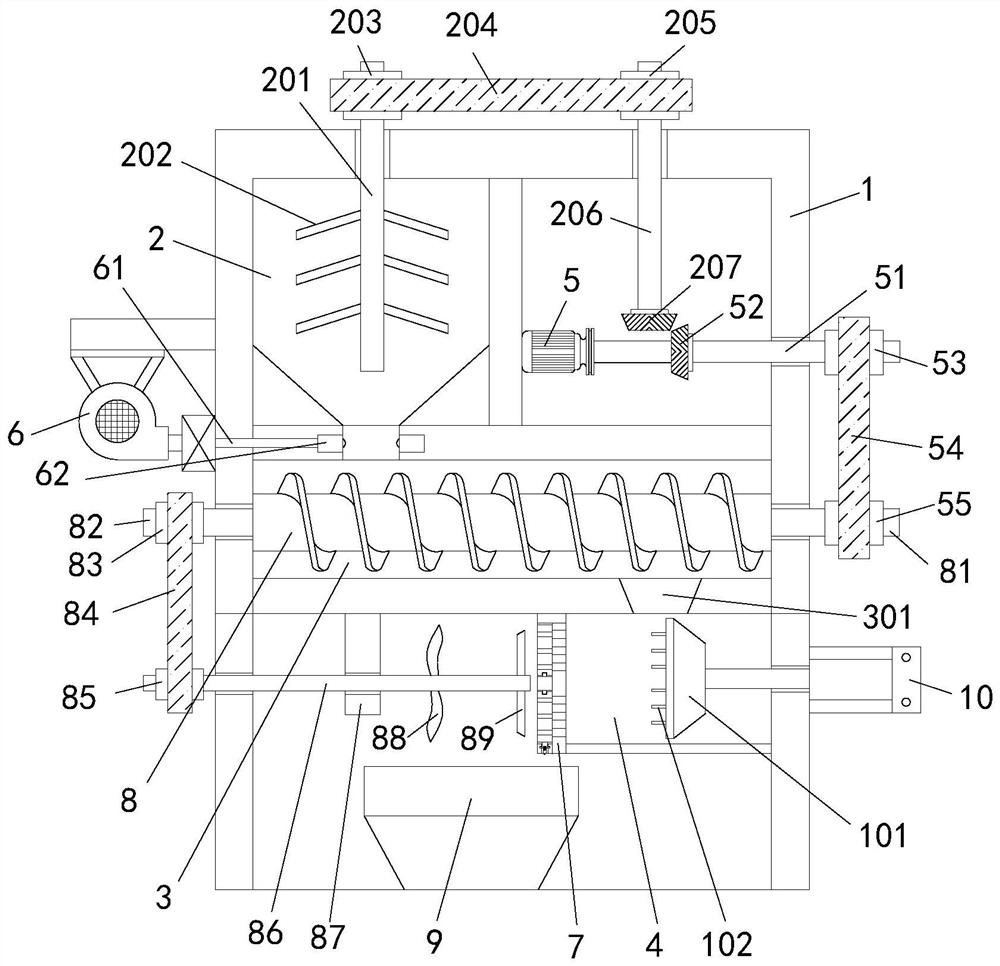

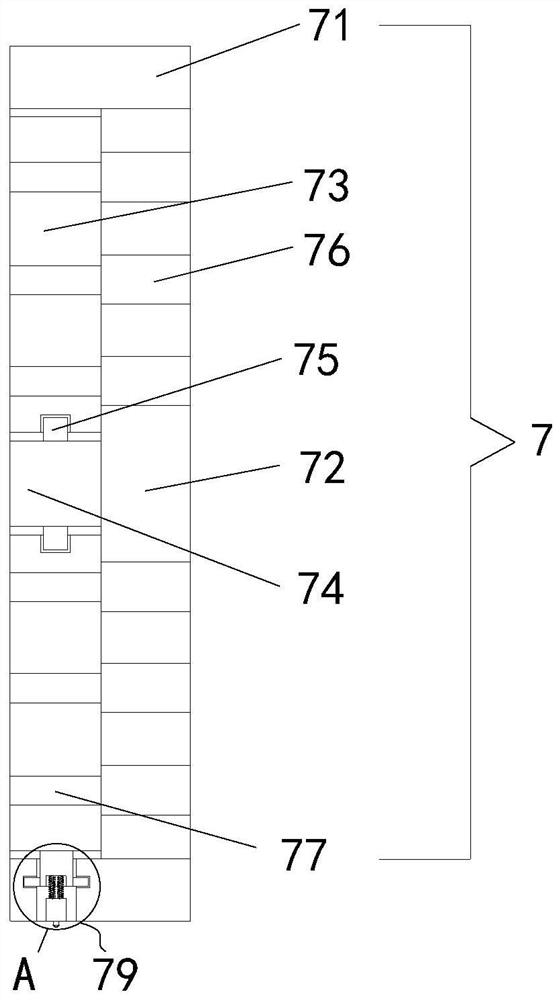

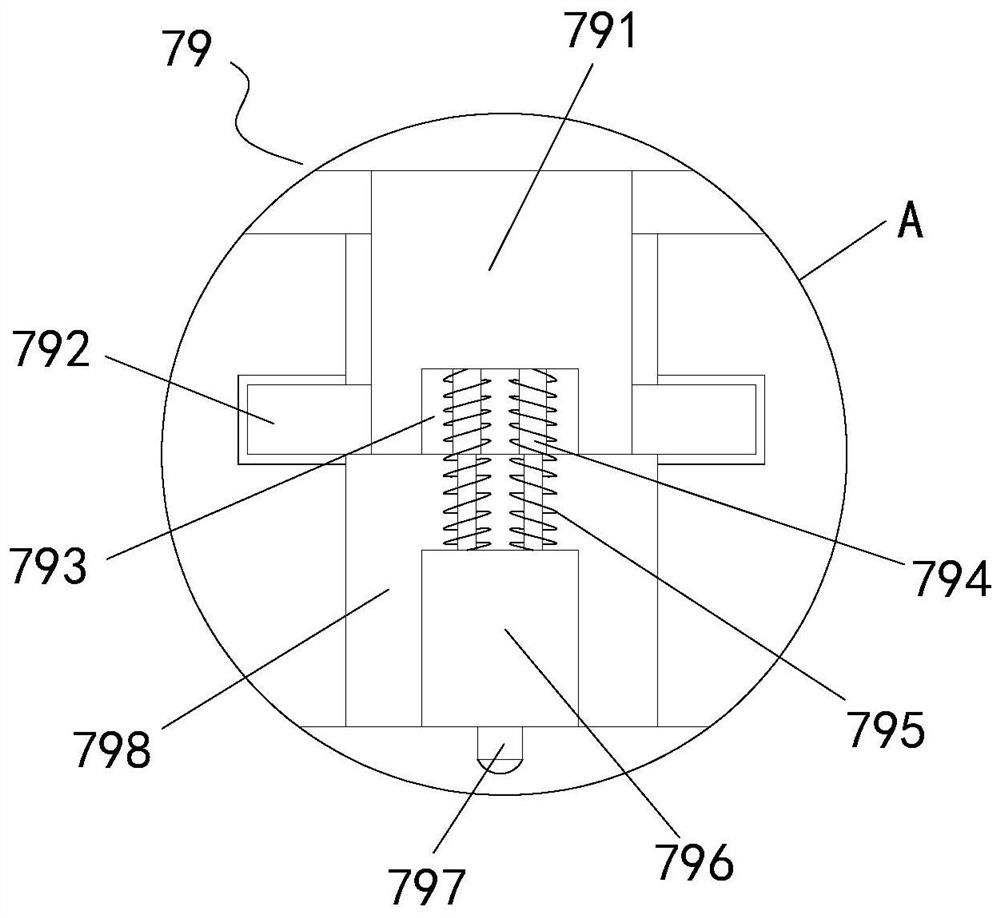

[0041] refer to Figure 1-8 , an adjustable granulation device for the production and processing of modified plastics, comprising a body shell 1, a stirring chamber 2, a screw feeding chamber 3 and a granulation chamber 4, and the mixing chamber 2, the screw feeding chamber 3 and the granulation chamber 4 are set In the body shell 1, and connected sequentially from top to bottom, the side wall of the mixing chamber 2 is provided with a heating assembly, which heats the mixing chamber 2, and the screw feeding chamber 3 is horizontally provided with a screw rod 8, and the screw rod 8 The first main shaft 81 and the second main shaft 82 are respectively provided at both ends of the shaft. The screw feeding chamber 3 and the granulation chamber 4 are connected through the discharge port 301; Stir and mix, and then go through the screw conveying in the screw feeding chamber 3, and enter the granulation chamber 4 through the discharge port 301 for extrusion and granulation;

[0042...

Embodiment 2

[0053] refer to Figure 1-8 , The difference between this embodiment and Embodiment 1 is that the mixing chamber 2 and the screw feeding chamber 3 are communicated through the feeding nozzle, and the outside of the feeding nozzle is provided with an annular air duct 62, and the annular air duct 62 is directed towards the feeding The side wall of the nozzle is surrounded by several groups of air outlets 63, and one side of the outer wall of the annular air duct 62 is connected with a cold air pipe 61, and the outwardly extending end of the cold air pipe 61 is provided with a cooling fan 6, and the cooling fan 6 is started, and the cold air passes through the cooling air The tube 61, the annular air duct 62, and the air outlet 63 are arranged at the feeding nozzle, so that the fused material can be heated and fused for preliminary cooling treatment, and the subsequent processing efficiency can be improved.

[0054] Refer to Example 1 for other undescribed structures.

[0055] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com