Compound fertilizer granulation assembly system

An assembly system and compound fertilizer technology, applied in the direction of fertilization device, fertilizer form, fertilizer mixture, etc., can solve the problems of low automation, low production quality, and weak system, and achieve high automation, low production cost, strong systemic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

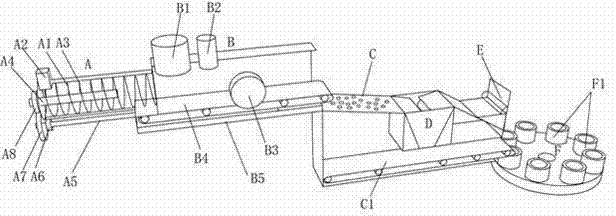

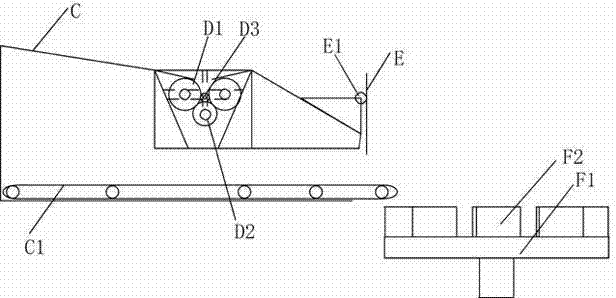

[0034] Such as Figure 1-2 As shown, the compound fertilizer granulation assembly system consists of 6 sets of devices, which are granulation device A, drying device B, screen C, pulverizer D, lifting baffle E and rotary charging device F. The granulation device A includes a drum A1, the top of the drum A1 is provided with a feed port A2, the middle of the drum A2 is provided with a worm conveyor A3, and the drum A1 is also provided with a rotary nozzle A4 at the same center as the worm conveyor. There is a drive rod A5 at the bottom of the drum A1, and the drive rod A5 is equipped with a drum driving wheel A6 and a rotating nozzle driving wheel A7. The rotating drum driving wheel A6 drives the rotating drum A1 to rotate, and the rotating nozzle driving wheel A7 drives the rotating nozzle. The rotary nozzle driven wheel A8 on A4 realizes driving the rotary nozzle A4;

[0035] The drying device B includes a conveyor belt B4 for receiving the material of the worm conveyor A3. T...

Embodiment 2

[0043] In this embodiment, the difference from Embodiment 1 is that the conveyor belt B4 can be a conveyor belt with mesh, which can facilitate the function of water entering the reservoir B5, and the rest of the working principles are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com