Potassium nitrate compound fertilizer and preparation process thereof

A compound fertilizer and preparation process technology, applied in the directions of nitrate fertilizer, urea compound fertilizer, ammonium orthophosphate fertilizer, etc., can solve the problems of inability to meet market demand, low compound fertilizer yield, etc. The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

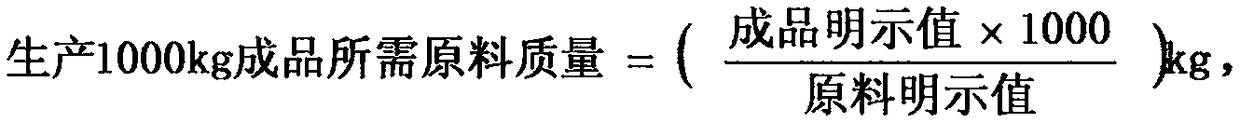

Method used

Image

Examples

Embodiment 1

[0019] The potassium nitrate compound fertilizer of the present invention comprises the following components in parts by weight: 35 parts of urea, 25 parts of monoammonium phosphate, 35 parts of potassium nitrate, 2.5 parts of ammonium bicarbonate, and 2.5 parts of calcium sulfate.

[0020] The potassium nitrate compound fertilizer preparation process comprises the steps:

[0021] (1) pulverizing: the urea that is 35 parts by weight, the monoammonium phosphate of 25 parts, the potassium nitrate of 35 parts, the ammonium bicarbonate of 2.5 parts and the calcium sulfate of 2.5 parts are pulverized through pulverizer;

[0022] (2) Stirring: the mixed pulverized material obtained in step (1) is sent into the stirring tank through the material conveyor belt for stirring, and the stirring time is 2 minutes, and the mixed material is stirred into the granulator after being evenly stirred;

[0023] (3) feed steam in the granulator in step (2), the water vapor pressure is about 9-12, t...

Embodiment 2

[0028] The potassium nitrate compound fertilizer of the present invention comprises the following components in parts by weight: 38 parts of urea, 23 parts of monoammonium phosphate, 34 parts of potassium nitrate, 2.4 parts of ammonium bicarbonate, and 2.6 parts of calcium sulfate.

[0029] The potassium nitrate compound fertilizer preparation process comprises the steps:

[0030] (1) pulverizing: the urea that is 38 parts by weight, the monoammonium phosphate of 23 parts, the potassium nitrate of 34 parts, the ammonium bicarbonate of 2.4 parts and the calcium sulfate of 2.6 parts are pulverized through pulverizer;

[0031] (2) Stirring: the mixed and pulverized material obtained in step (1) is sent into the millstone mixing tank through the material conveyor belt for stirring, and the stirring time is 3 minutes, and the mixed material is passed into the granulator after being evenly stirred;

[0032] (3) feed steam in the granulator in step (2), the water vapor pressure is ab...

Embodiment 3

[0037] The potassium nitrate compound fertilizer of the present invention comprises the following components in parts by weight: 40.5 parts of urea, 22.5 parts of monoammonium phosphate, 32.2 parts of potassium nitrate, 2.4 parts of ammonium bicarbonate, and 2.4 parts of calcium sulfate.

[0038] The potassium nitrate compound fertilizer preparation process comprises the steps:

[0039] (1) pulverizing: the urea that is 40.5 parts by weight, the monoammonium phosphate of 22.5 parts, the potassium nitrate of 32.2 parts, the ammonium bicarbonate of 2.4 parts and the calcium sulfate of 2.4 parts are pulverized through pulverizer;

[0040] (2) Stirring: the mixed pulverized material obtained in step (1) is sent into the millstone mixing tank through the material conveyor belt for stirring, and the stirring time is 4 minutes, and the mixed material is passed into the granulator after the mixed material is evenly stirred;

[0041] (3) feed steam in the granulator in step (2), the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com