Combined ejection prilling tower compound fertilizer prilling method

A technology of granulating tower and compound fertilizer, which is applied in the direction of urea compound fertilizer, nitrogen fertilizer, fertilizer form, etc., can solve the problems of complex structure of process equipment, high cost of facilities, low production capacity and cost-effectiveness, etc. Small and cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

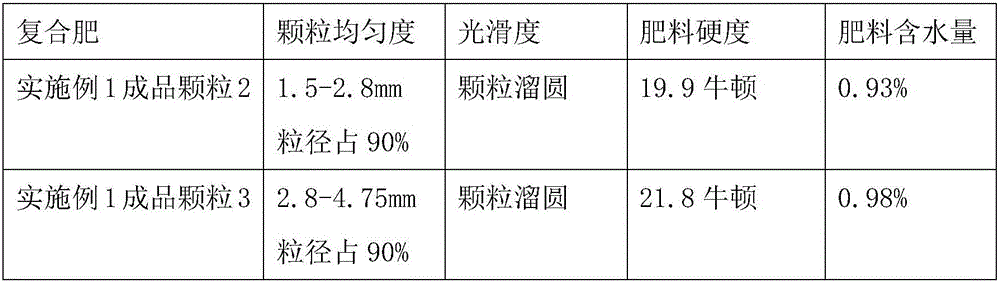

Examples

Embodiment 1

[0028] Step 1) Prepare nitrophosphate compound fertilizer, potash fertilizer and phosphate fertilizer into molten slurry according to conventional methods.

[0029] Step 2) Turn on the high-pressure blower to lead the high-pressure air into the ejector 1 .

[0030] Step 3) Prepare medium and trace elements, zeolite powder, bentonite, fertilizer and the like into small granular materials according to conventional methods.

[0031] Step 4) Ejector 1 introduces the molten slurry and small particles in step 1) into the mixing chamber at a weight ratio of 1:1 through the negative pressure generated during the slurry conveying process to form material liquid 1.

[0032] Step 5) The high-pressure gas in the injector 1 passes the feed liquid through the diffusion tube to form a gas-liquid mixture, and simultaneously sprays the gas-liquid mixture into the prilling tower 1 with the injection direction as the horizontal direction, and the volume ratio of gas and feed liquid is 10000:1 T...

Embodiment 2

[0038] Step 1) Prepare nitrophosphate compound fertilizer, potash fertilizer and phosphate fertilizer into molten slurry according to conventional methods.

[0039] Step 2) Turn on the high-pressure blower to lead the high-pressure air into the ejector 1 .

[0040] Step 3) Prepare medium and trace elements, zeolite powder, bentonite, fertilizer and the like into small granular materials according to conventional methods.

[0041] Step 4) Ejector 1 introduces the molten slurry and small particles in step 1) into the mixing chamber at a weight ratio of 1:1 through the negative pressure generated during the slurry conveying process to form material liquid 1.

[0042]Step 5) The high-pressure gas in the injector 1 passes the feed liquid through the diffusion tube to form a gas-liquid mixture, and at the same time sprays the gas-liquid mixture into the prilling tower 1 with the injection direction as the horizontal direction, and the volume ratio of gas and feed liquid is 10000:2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com