Feed extruding and granulating device for livestock feed processing

A technology of extrusion granulation and feed processing, applied in the direction of raw material extrusion granulation, feed, application, etc., can solve the problems of insufficient dispersion of feed granules, low work efficiency, slow granulation speed, etc., and achieve good extrusion effect, The effect of high work efficiency and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with specific embodiment, the technical scheme of this patent is described in further detail:

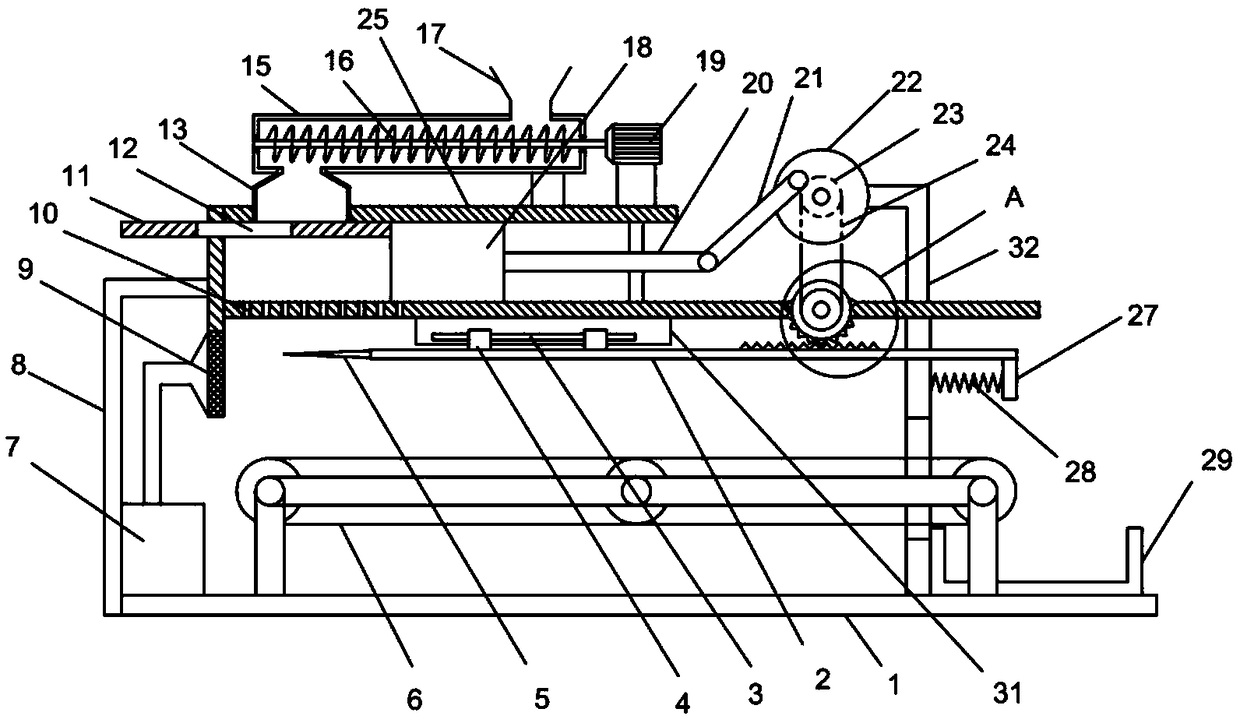

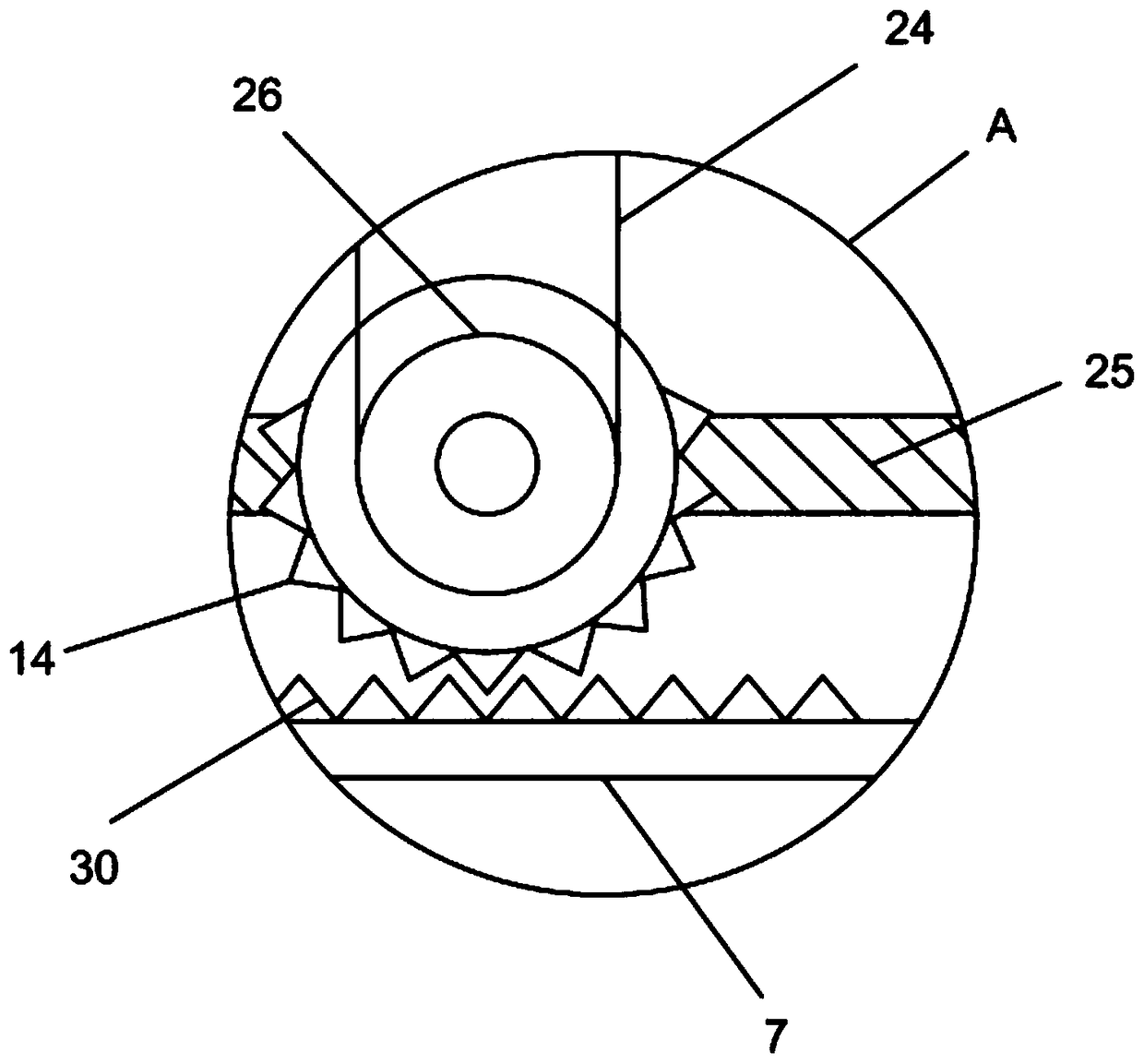

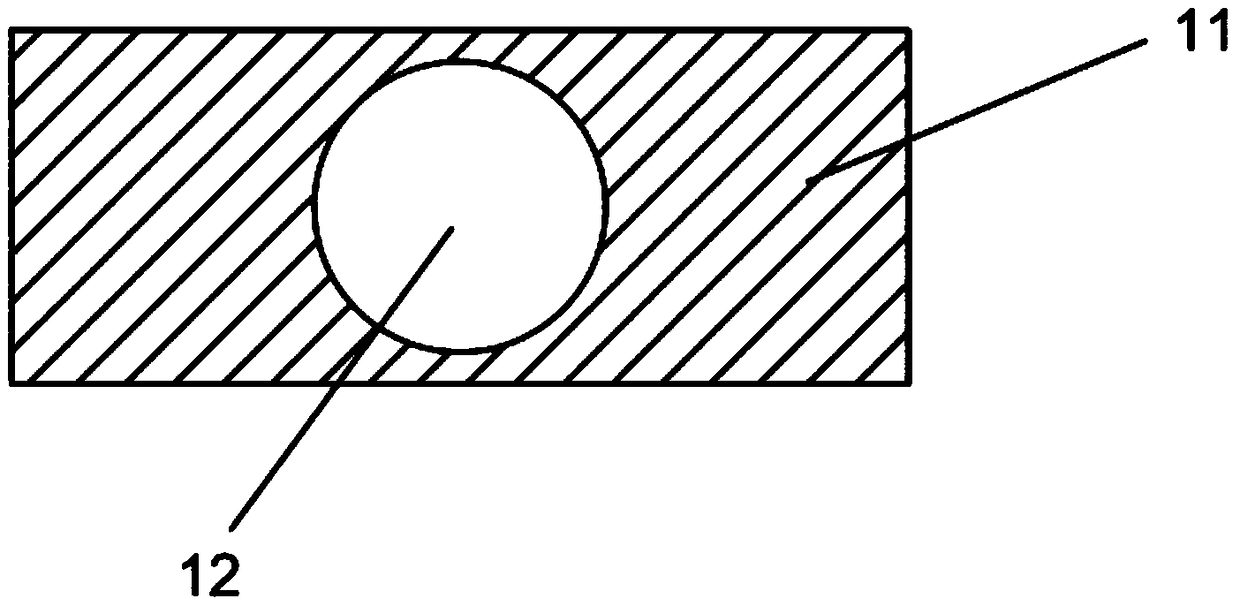

[0020] see Figure 1-3 , a feed extrusion granulation device for livestock feed processing, comprising a base plate 1, a support frame 8 is fixed vertically on the base plate 1, a limit extrusion cylinder 25 is fixedly installed on the support frame 8, a limit extrusion cylinder The horizontal sliding type in 25 is provided with a sliding block 18, and the upper left end of the sliding block 18 is horizontally and fixedly installed with a sliding plate 11 whose upper surface abuts against the inner side wall of the limit extrusion cylinder 25, and a feeder is provided vertically on the sliding plate 11. Channel 12; the limit extrusion cylinder 25 is horizontally fixed with a conveying cover 15, and the horizontal rotation of the conveying cover 15 is provided with a screw conveying shaft 16, and the limit extrusion cylinder 25 is fixedly installed with an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com