PVC (Polyvinyl Chloride)/graphite alkene antistatic composite material and preparation method thereof

A composite material and antistatic masterbatch technology, applied in the field of PVC/graphene antistatic composite material and its preparation, to achieve excellent comprehensive performance, solve poor processing performance, and ensure the effect of electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

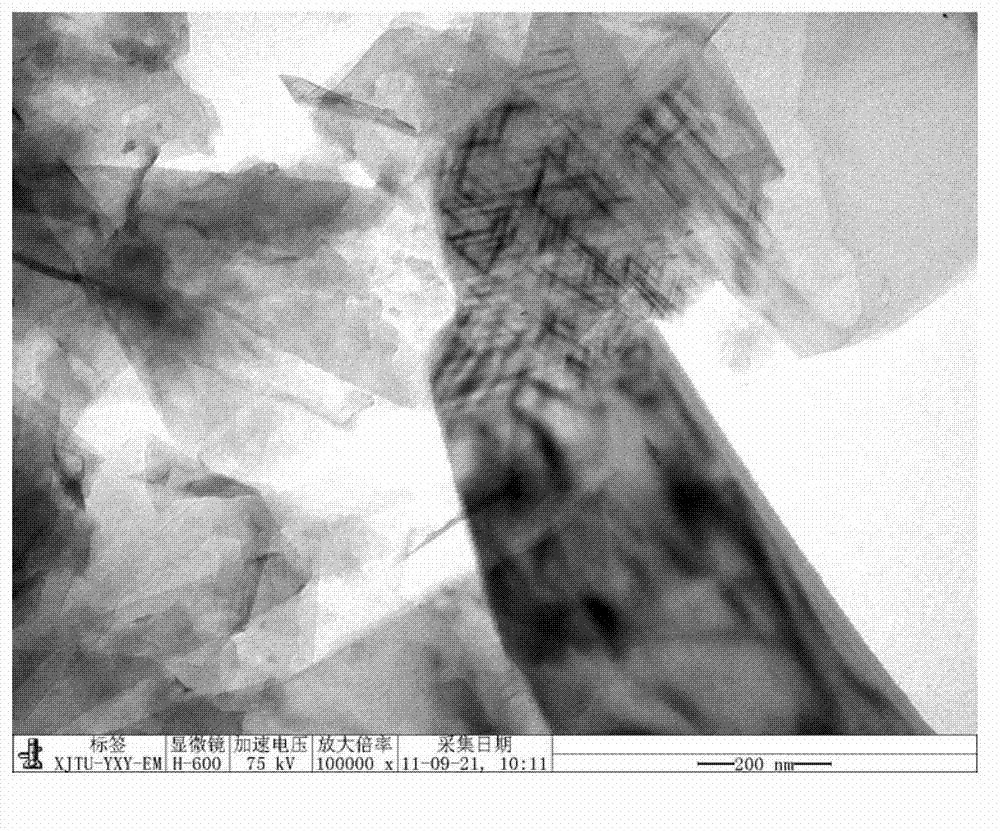

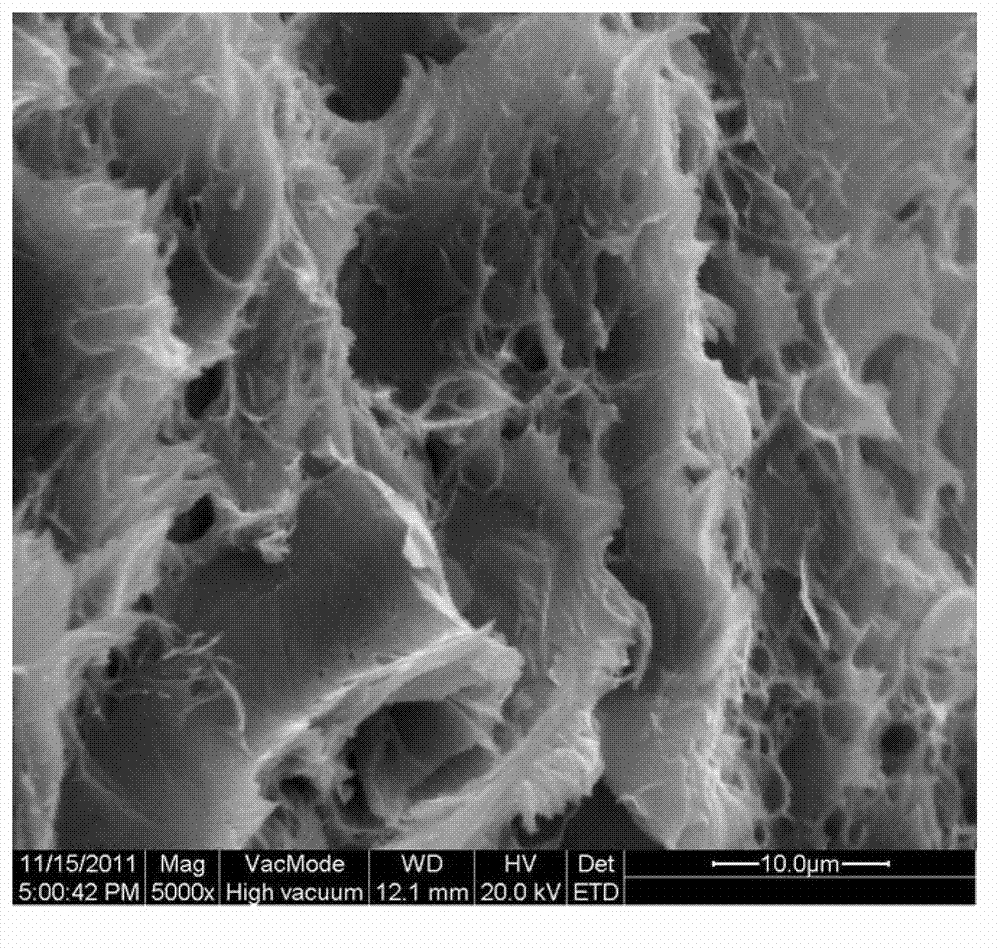

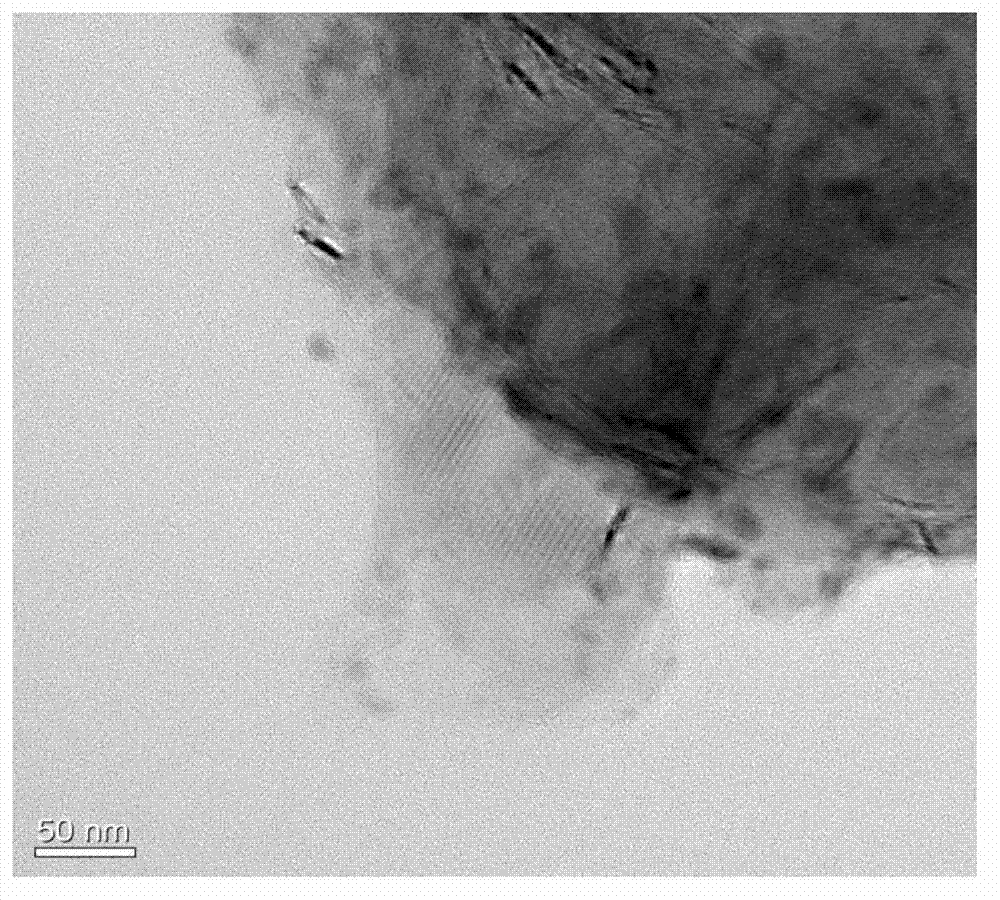

[0039]The PVC / graphene antistatic composite material of the present embodiment is characterized in that it is made of the following raw materials in weight percentage: 9.5% impact modifier, 4.5% conductive filler, 3.5% processing aid, and 82.5% matrix resin; The impact modifier is chlorinated polyethylene and a copolymer of methyl methacrylate and acrylate (mass ratio 8.9:0.6); the conductive filler is expanded graphite; the processing aid consists of a heat stabilizer It is mixed with lubricant according to the mass ratio of 2.9:0.6, wherein the heat stabilizer is N-phenylmaleamide radical lanthanum, and the lubricant is stearic acid and paraffin (mass ratio 1:1); the base resin It is polyvinyl chloride; the expanded graphite is made of expandable graphite (commercially available Kp25) with an expansion rate of 200-350 and expanded by microwave irradiation with a frequency of 2450MHz for 10s.

[0040] The preparation method of the PVC / graphene antistatic composite material of...

Embodiment 2

[0051] The PVC / graphene antistatic composite material of the present embodiment is characterized in that it is made of the following raw materials in weight percentage: 8% impact modifier, 3% conductive filler, 14% processing aid, and 75% matrix resin; The impact modifier is chlorinated polyethylene and a copolymer of methyl methacrylate and acrylate (mass ratio 7.6:0.4); the conductive filler is expanded graphite; the processing aid consists of a heat stabilizer , lubricant and plasticizer are mixed according to the mass ratio of 3.6:0.4:10, wherein the thermal stabilizer is N-phenylmaleamide lanthanum, and the lubricant is stearic acid and paraffin (mass ratio 1:1 ), the plasticizer is polyethylene adipate with a molecular weight of 2250; the matrix resin is polyvinyl chloride; the expanded graphite is composed of expandable graphite (commercially available Kp32) with an expansion ratio of 200 to 400. Made by 2450MHz microwave irradiation for 3s.

[0052] The preparation me...

Embodiment 3

[0062] The PVC / graphene antistatic composite material of the present embodiment is characterized in that it is made of the following raw materials in weight percentage: 5% impact modifier, 5% conductive filler, 5% processing aid, and 85% matrix resin; The impact modifier is chlorinated polyethylene and a copolymer of methyl methacrylate and acrylate (mass ratio 3:2); the conductive filler is expanded graphite; the processing aid consists of a heat stabilizer It is mixed with a lubricant at a mass ratio of 3:2, wherein the heat stabilizer is N-phenylmaleamide lanthanum, and the lubricant is stearic acid and paraffin (mass ratio 1:1); the base resin It is polyvinyl chloride; the expanded graphite is made of expandable graphite (commercially available Kp32) with an expansion rate of 200-400 and expanded by microwave irradiation with a frequency of 2450MHz for 15s.

[0063] The preparation method of the PVC / graphene antistatic composite material of the present embodiment is:

[0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com