Preparation method of aluminium base zirconium tungstate particle composite material

A composite material, aluminum-based tungstic acid technology, applied in the field of aluminum-based materials, can solve the problems of affecting negative thermal expansion performance, particle content limitation, difficult to fully densify, etc., and achieve the effect of high bonding strength and high volume fraction ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] 1. ZrW 2 o 8 Preparation of powder Put 65g of zirconium oxychloride (ie: 0.2mol) in 200ml of deionized water and stir repeatedly, and another 106g of ammonium paratungstate (ie: 0.4mol) in 400ml of deionized water and repeatedly stir (ie: 0.2mol); Mix the zirconium oxychloride solution with the ammonium paratungstate solution prepared above under strong stirring conditions, add ammonia water and hydrochloric acid to adjust the pH value to 4.0; Clear liquid; after drying in a drying oven at 100°C, grind it finely, press it into a compact with a diameter of 25mm under a pressure of 100MPa, and place it in a sintering furnace at 600°C for 13 hours; then place it in a sintering furnace at 1200°C Reaction in the furnace for 3 hours; grinding for 40 minutes into powder.

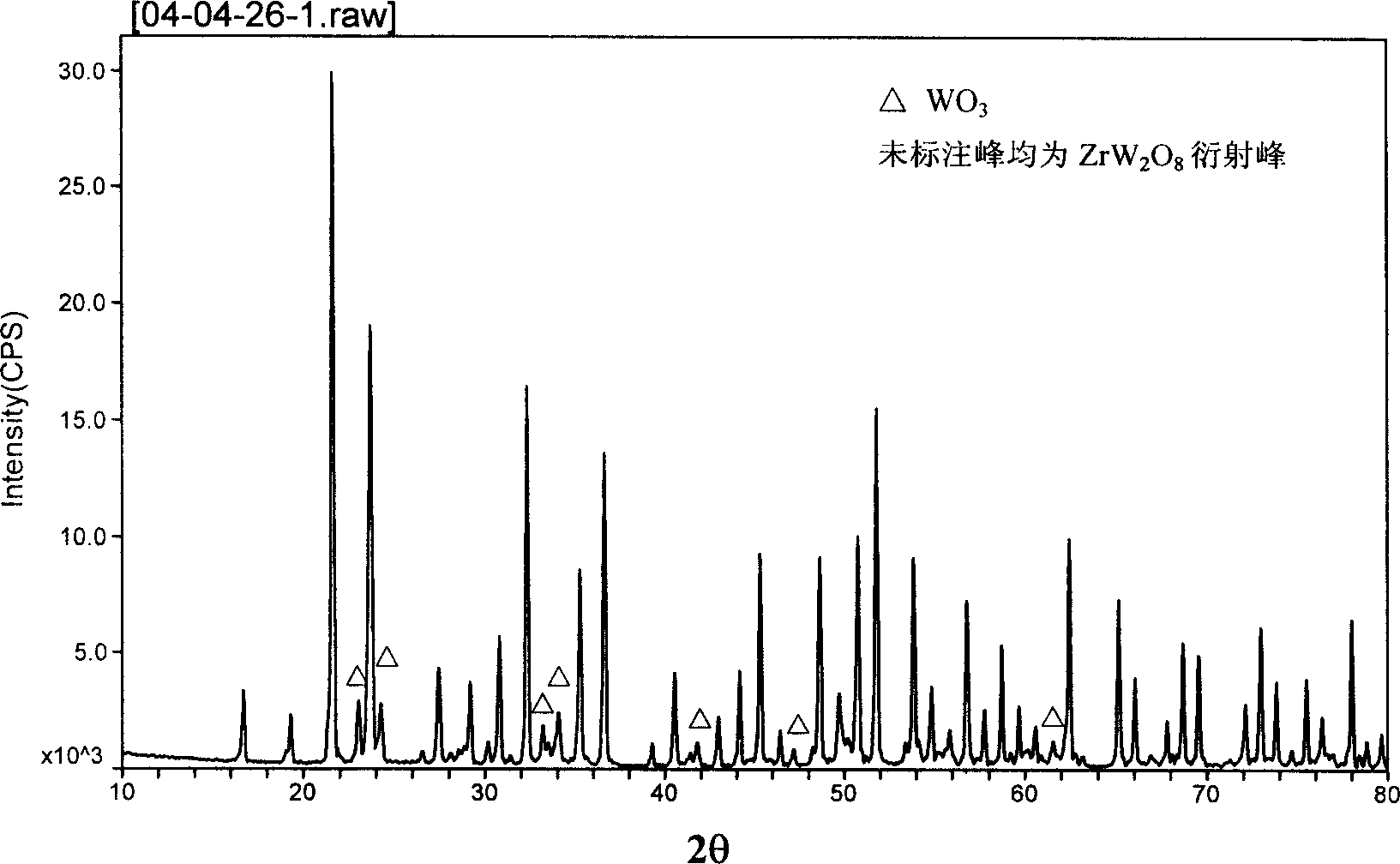

[0027] figure 1 It is the ZrW synthesized by the reaction of Example 1 2 o 8 X-ray diffraction pattern of the powder, except a very small amount of WO 3 In addition, it is basically a single phase ZrW ...

Embodiment 2

[0036] 1. ZrW 2 o 8 Preparation of powder Put 65g of zirconium oxychloride (ie: 0.2mol) in 200ml of deionized water and stir repeatedly, and another 106g of ammonium paratungstate (ie: 0.4mol) in 400ml of deionized water and repeatedly stir (ie: 0.2mol); Mix the zirconium oxychloride solution with the ammonium paratungstate solution prepared above under strong stirring conditions, add ammonia water and hydrochloric acid to adjust the pH value to 4.0; Clear liquid; after drying in a drying oven at 100°C, grind it finely, press it into a compact with a diameter of 25mm under a pressure of 100MPa, and place it in a sintering furnace at 600°C for 13 hours; then place it in a sintering furnace at 1200°C Reaction in the furnace for 3 hours; grinding into powder for 2 hours.

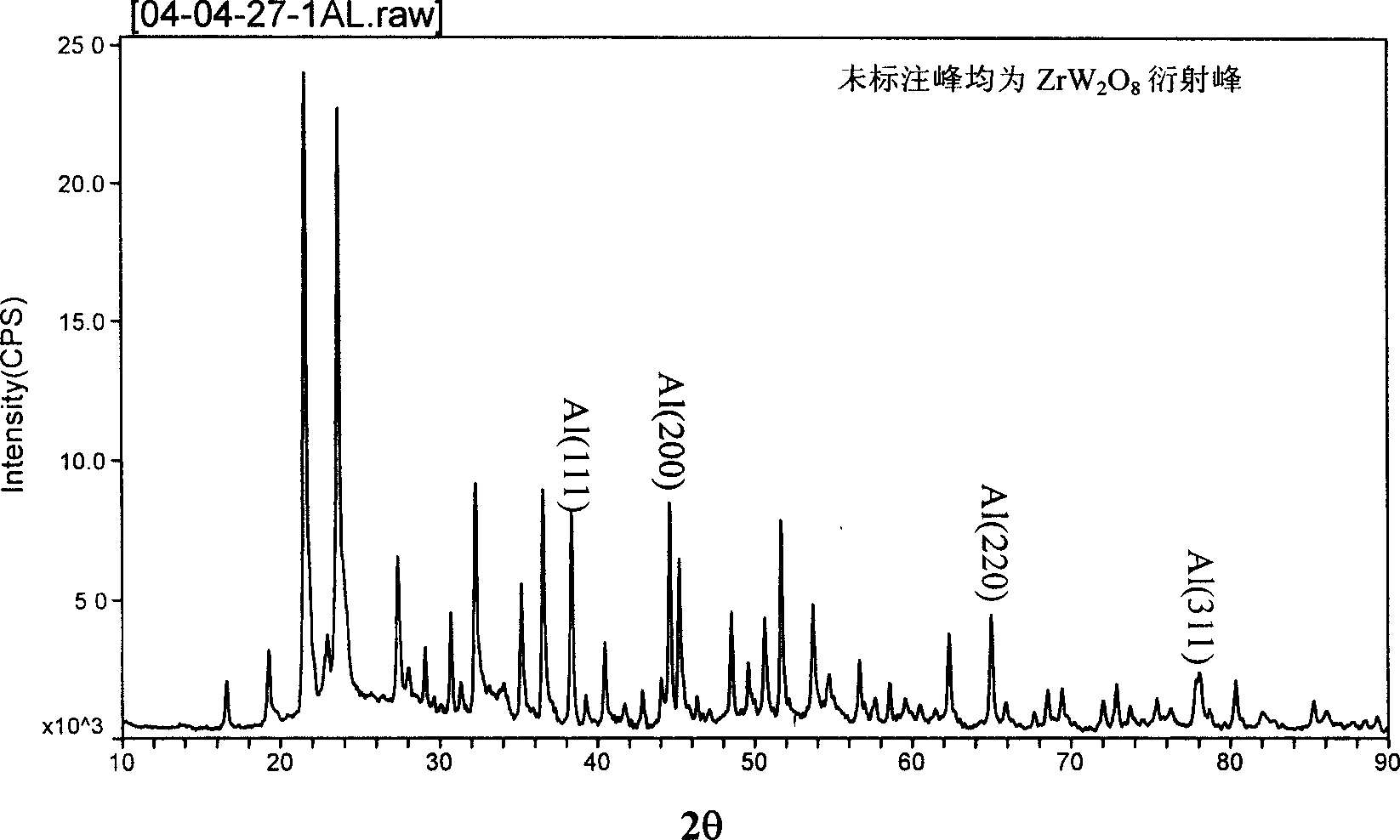

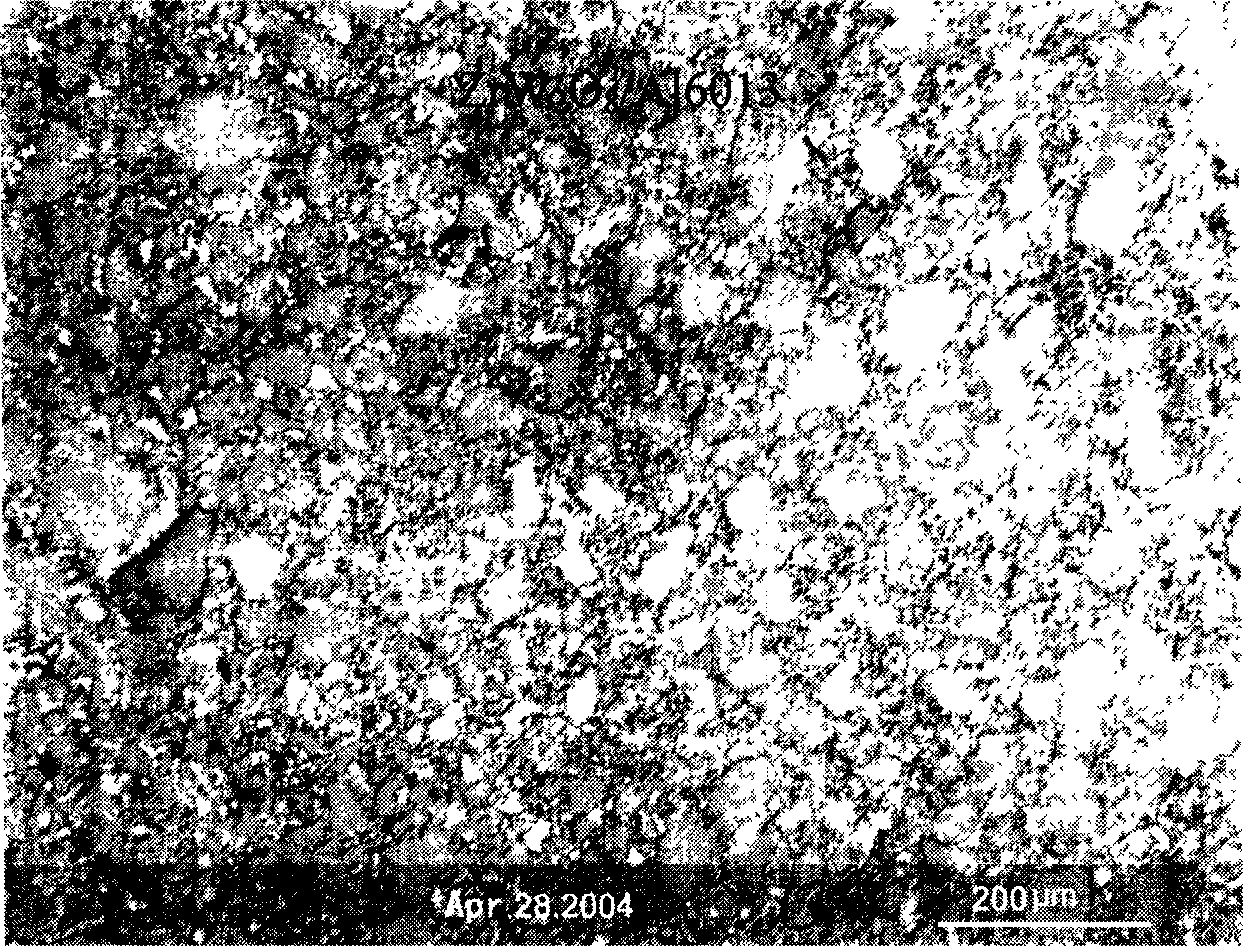

[0037] 2. ZrW 2 o 8 / Al6013 composite material will be prepared ZrW 2 o 8 The powder is compressed into a preform with a diameter of 45mm under a pressure of 377MPa, and placed in a heat-resistant steel (...

Embodiment 3

[0045] 1. ZrW 2 o 8 Preparation of powder: Put 55g of ammonium paratungstate (ie: 0.20mol) in a mortar and grind it finely, put it into a beaker, add nitric acid and stir, adjust the pH value to 1.0, after the ammonium paratungstate is completely dissolved, add ammonia water to make the pH value 7.0, stir When the solution is clear, nitric acid is added to adjust the pH value to 5.0.

[0046] Dissolve 33.17g of zirconium oxychloride (ie: 0.103mol), mix the zirconium oxychloride solution with the ammonium paratungstate solution prepared above under strong stirring conditions, and add nitric acid to keep the pH value at 4.0; continue stirring for 1 hour After standing still for several hours until the supernatant appears in the upper layer, suck out the supernatant; dry it in a drying oven at 100°C and grind it finely, press it into a compact with a diameter of 25mm under a pressure of 100MPa, and place it in a sintering chamber at 600°C React in the furnace for 13 hours, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear expansion coefficient | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com