Large-scale ink-jet printing method for three-dimensional metamaterial array

A technology of inkjet printing and metamaterials, applied in printing devices, printing, etc., to achieve the effects of high graphics preparation efficiency, avoid damage, and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

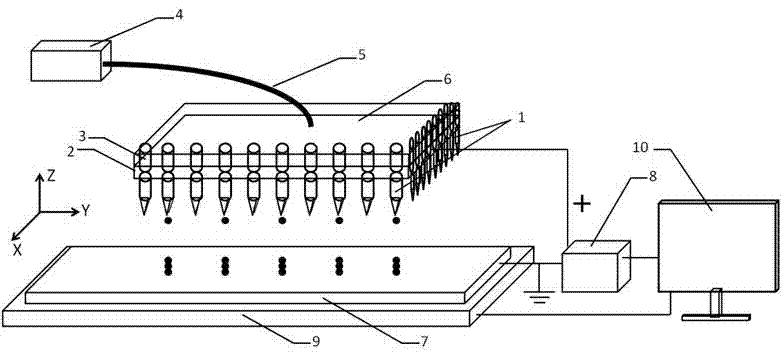

[0042] The printing device used in this embodiment is as image 3 As shown, it includes a nozzle 1 , an electrode layer 2 , an ink cartridge 3 , a syringe pump 4 , a gas pipe 5 , a gas distribution device 6 , a substrate 7 , a power source 8 , a motorized stage 9 and a computer 10 .

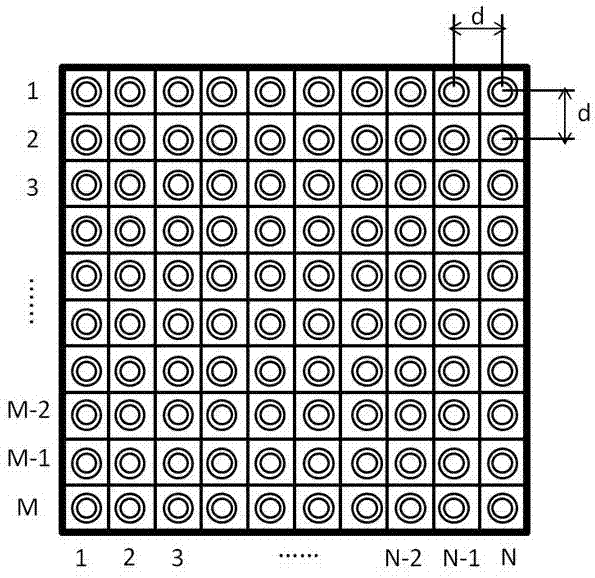

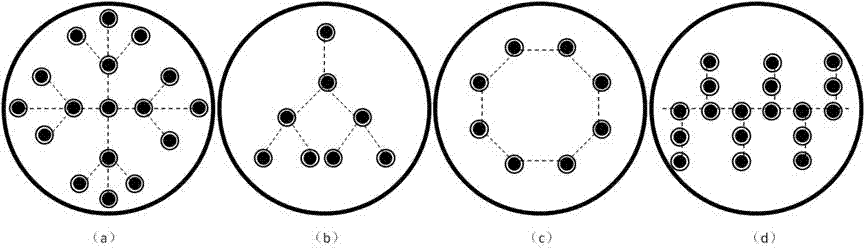

[0043] Among them, the nozzle structure has been specially designed, including such as figure 1 Universal applicators as shown, and as figure 2 The difference of the special nozzle shown is the nozzle array: the general nozzle contains M×N nozzles (1) array, while the nozzle array of the special nozzle has formed the required topology. In both cases, the nozzles are connected to the electrode layer (2), and the corresponding position of each nozzle in the electrode layer is connected to a separate ink cartridge (3), which is filled with ink for inkjet printing. The nozzles adopt the principle of electrodynamic fluid inkjet printing, and are insulated from each other with a distance of d , in...

Embodiment 2

[0051] Applied to the printing of a variety of three-dimensional topological structure graphics arrays, using a general-purpose nozzle, the inkjet of each nozzle can be controlled individually. If the substrate does not move, a single nozzle repeatedly prints on the previous ink dot to obtain a single three-dimensional nanowire. The diameter of the nanowire is the ink dot size. The software program is set to apply voltage to multiple nozzles, and the working nozzle arrays form a specific pattern together, and the required three-dimensional metamaterial array unit is directly printed. Using a special nozzle, the matching three-dimensional metamaterial array graphics unit can be directly printed. Move the substrate and print on another area of the substrate to get another unit. The operation is performed several times to obtain a large-area periodic structure.

Embodiment 3

[0053] Complex graphics unit printing. 1. Nanowires of different sizes: The size of nanowires includes diameter and height (length). Each nozzle can work independently. By adjusting printing parameters, nanowires of different sizes can be obtained. The nozzles of one graphics unit work at the same time, and the size of each nanowire in the array unit can be controlled. 2. Inclined, curved, and helical nanowire arrays: During inkjet printing, move the stage at a fixed speed along one of the x or y axes to obtain nanowires inclined at a certain angle (moving along the positive direction of the x axis, the nanometer The wire tilts towards the negative direction of the x-axis; when moving along the negative direction of the x-axis, the nanowire tilts towards the positive direction of the x-axis; when moving along the positive direction of the y-axis, the nanowire tilts toward the negative direction of the y-axis; when moving along the negative direction of the y-axis, the nanowire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com