Method and device for realizing uniform heating by utilizing frequency modulation of a single solid-state source

A technology of uniform heating and solid-state source, applied in microwave heating and other directions, can solve the problems of high heating cost and complex structure, and achieve the effects of low cost, good heating uniformity and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

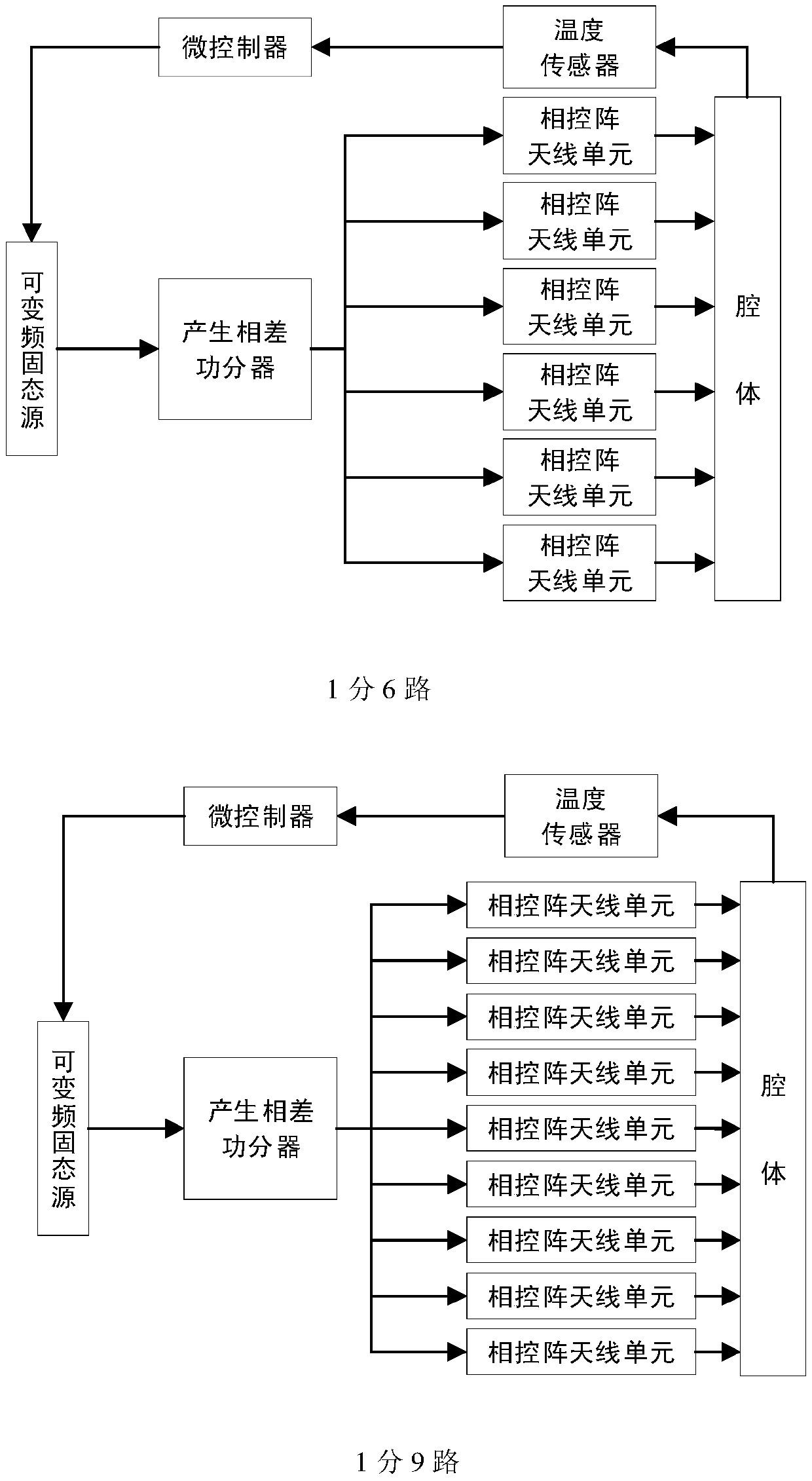

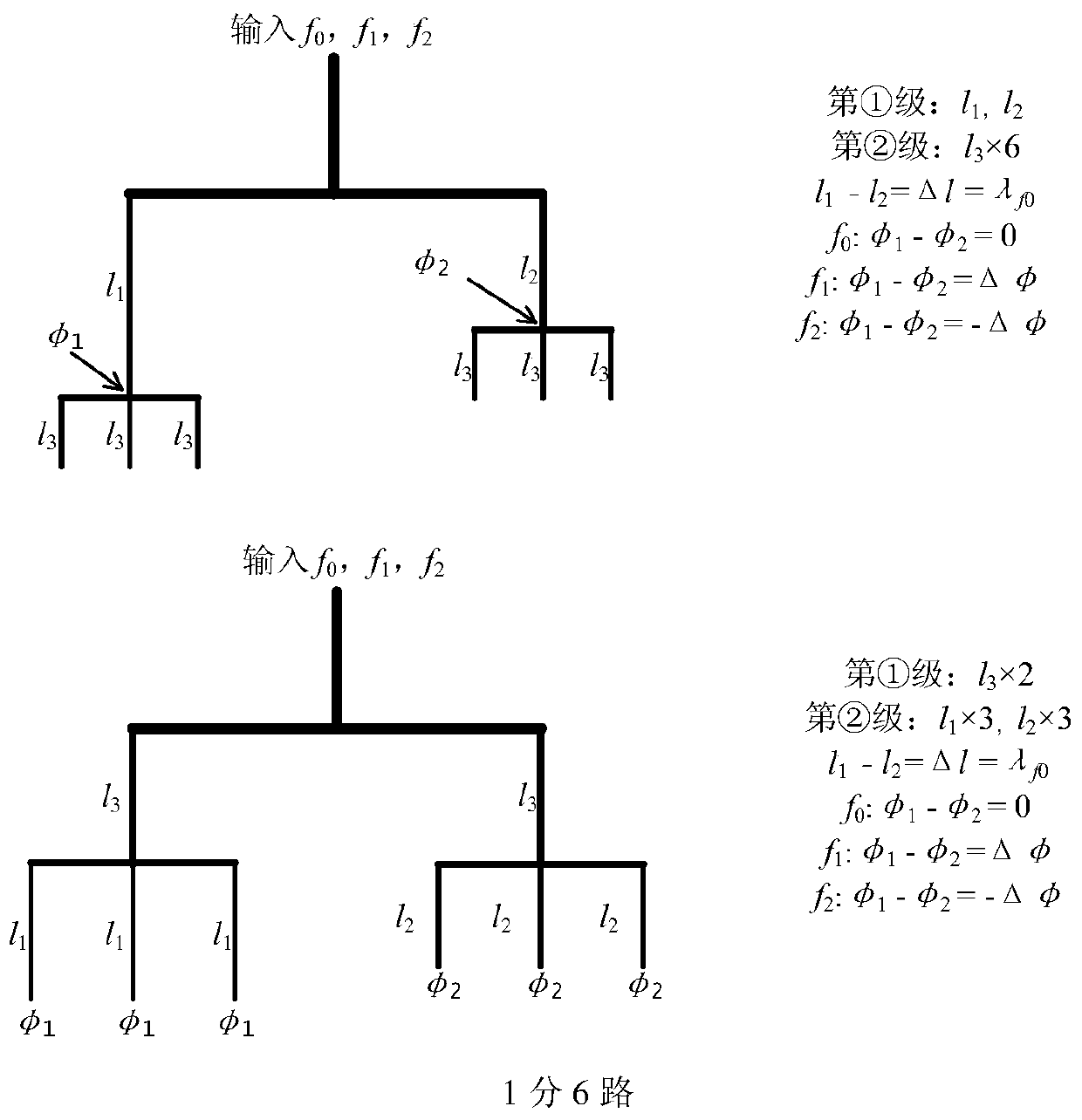

[0035]The antenna radiation device and the temperature feedback device are arranged in the heating chamber 8; the single solid-state source 4 is connected to the antenna radiation device through the power divider 3; the microcontroller 6 is connected to the single solid-state source 4 and the temperature feedback device; the power divider 3 is 1 point 6-way power divider, including power divider 3 stage ① and power divider 3 stage ②; the power divider 3 includes dividing electromagnetic energy into 2 groups × 3 paths and 2 groups of electromagnetic energy phase difference both Or 0 microstrip circuit or other microwave devices with the same function. Among them, the length difference of the 2-way microstrip circuit in the first stage of the power divider 3 is l 1 -l 2 = Δl is set to the center frequency f 0 Propagation wavelength λ in the medium f0 , or wavelength λ f0 The integer multiple antenna radiation device is a 2×3 array antenna composed of 6 microstrip patch ant...

specific Embodiment 2

[0042] (one)

[0043] The antenna radiation device and the temperature feedback device are arranged in the heating chamber 8; the single solid-state source 4 is connected to the antenna radiation device through the power divider 3; the microcontroller 6 is connected to the single solid-state source 4 and the temperature feedback device; The device 3 is two groups of microwave devices; they are 1-9-way power splitters, including the first stage of the power splitter 3 and the second stage of the power splitter 3; the power splitter 3 divides the electromagnetic energy into 3 groups × 3 roads And the phase difference of the three groups of electromagnetic energy is or 0 microstrip circuits. The single solid-state source 4 frequencies output electromagnetic wave energy of different powers and frequencies at different times to the stage ① of the power divider 3. Due to the length difference Δl of the microstrip circuit, the phase difference of the electromagnetic wave output by ...

specific Embodiment 3

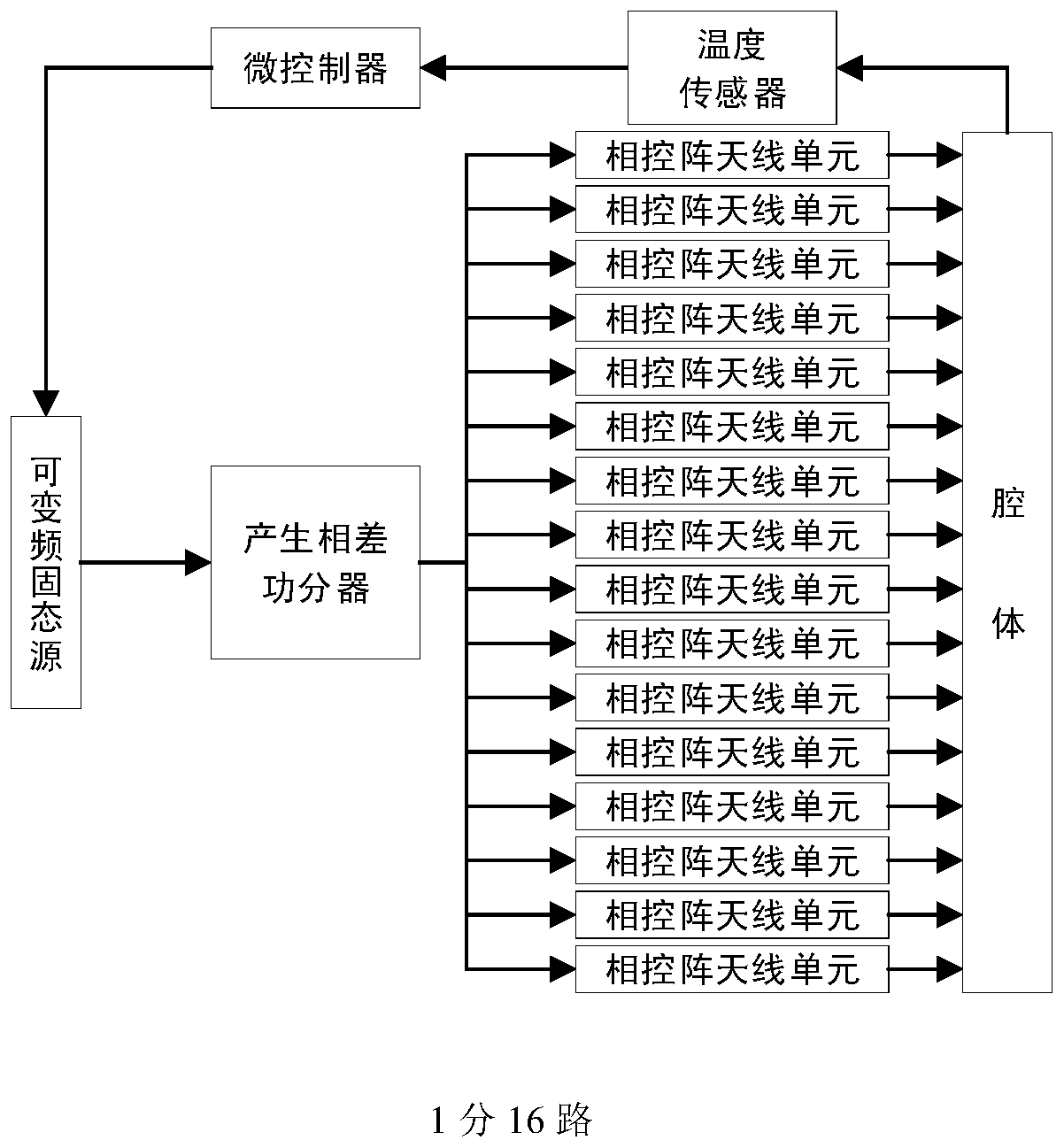

[0058] The antenna radiation device and the temperature feedback device are arranged in the heating chamber 8; the solid-state source is connected to the antenna radiation device through the power divider 3; the microcontroller 6 is connected to the solid-state source and the temperature feedback device; in this embodiment, the power divider 3 is 1 Divide 16-way power divider 3, including power divider 3 stage ① and power divider 3 stage ②; power divider 3 divides the electromagnetic energy into 4 groups × 4 paths, and the phase difference of the electromagnetic energy of the 4 groups is equal to Or 0 microstrip circuit or other microwave devices with the same function. The solid-state source outputs electromagnetic wave energy of different powers and frequencies to the stage ① of the power divider 3 at different times. Due to the length difference Δl of the microstrip circuit, the phase difference of the electromagnetic wave output by the stage ① of the power divider 3 is diff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com