Patents

Literature

42results about How to "Maximize removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

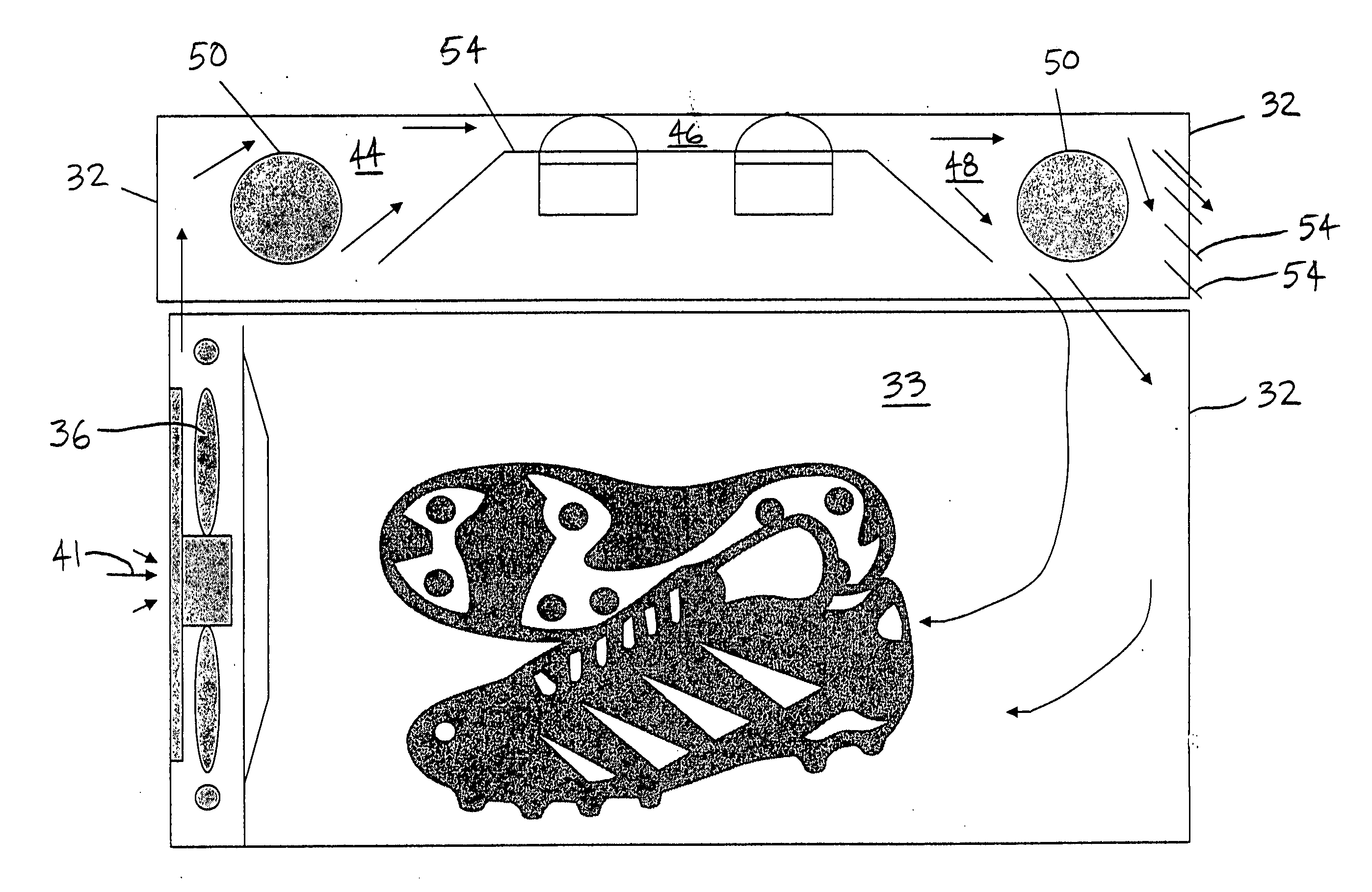

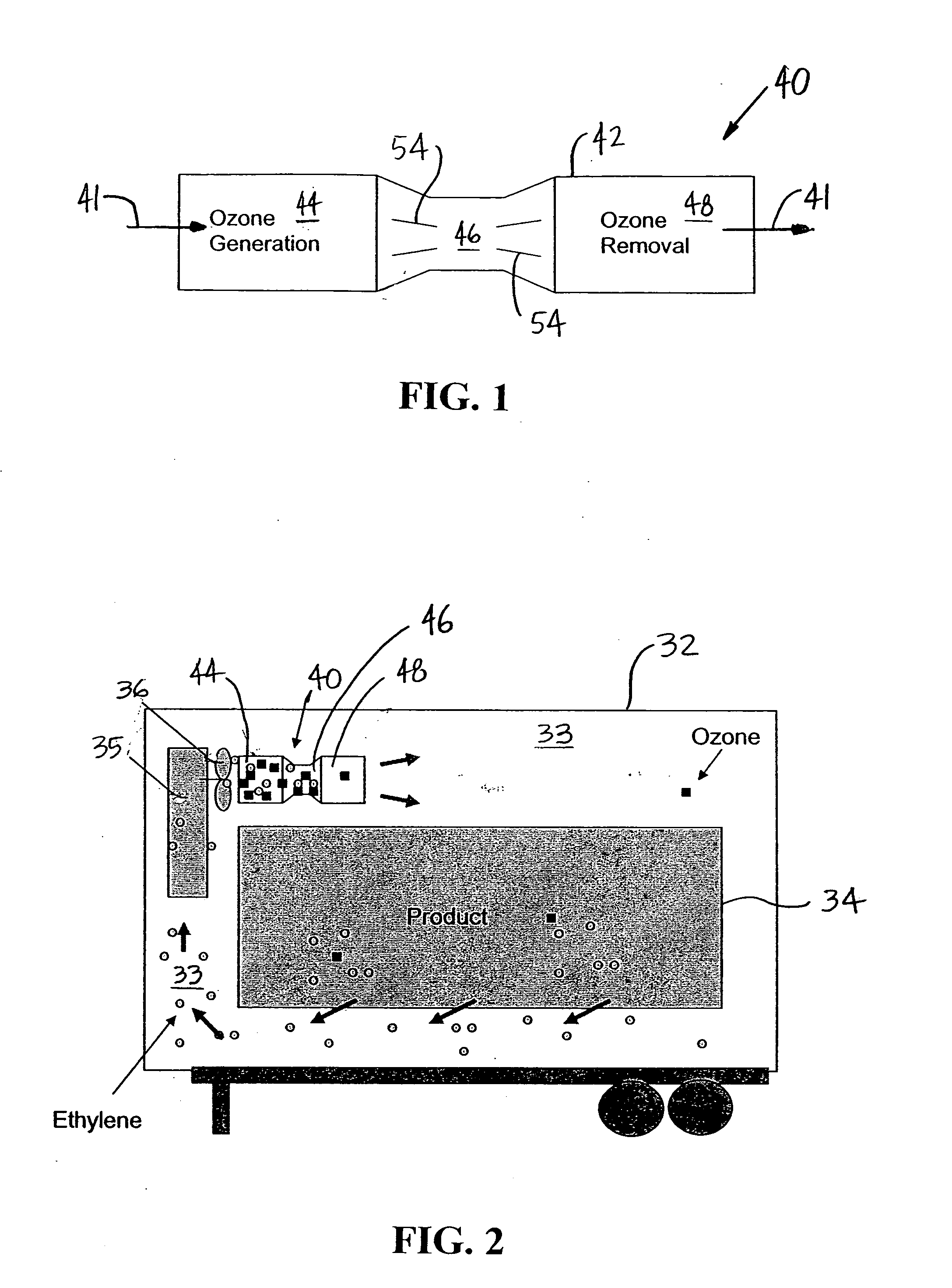

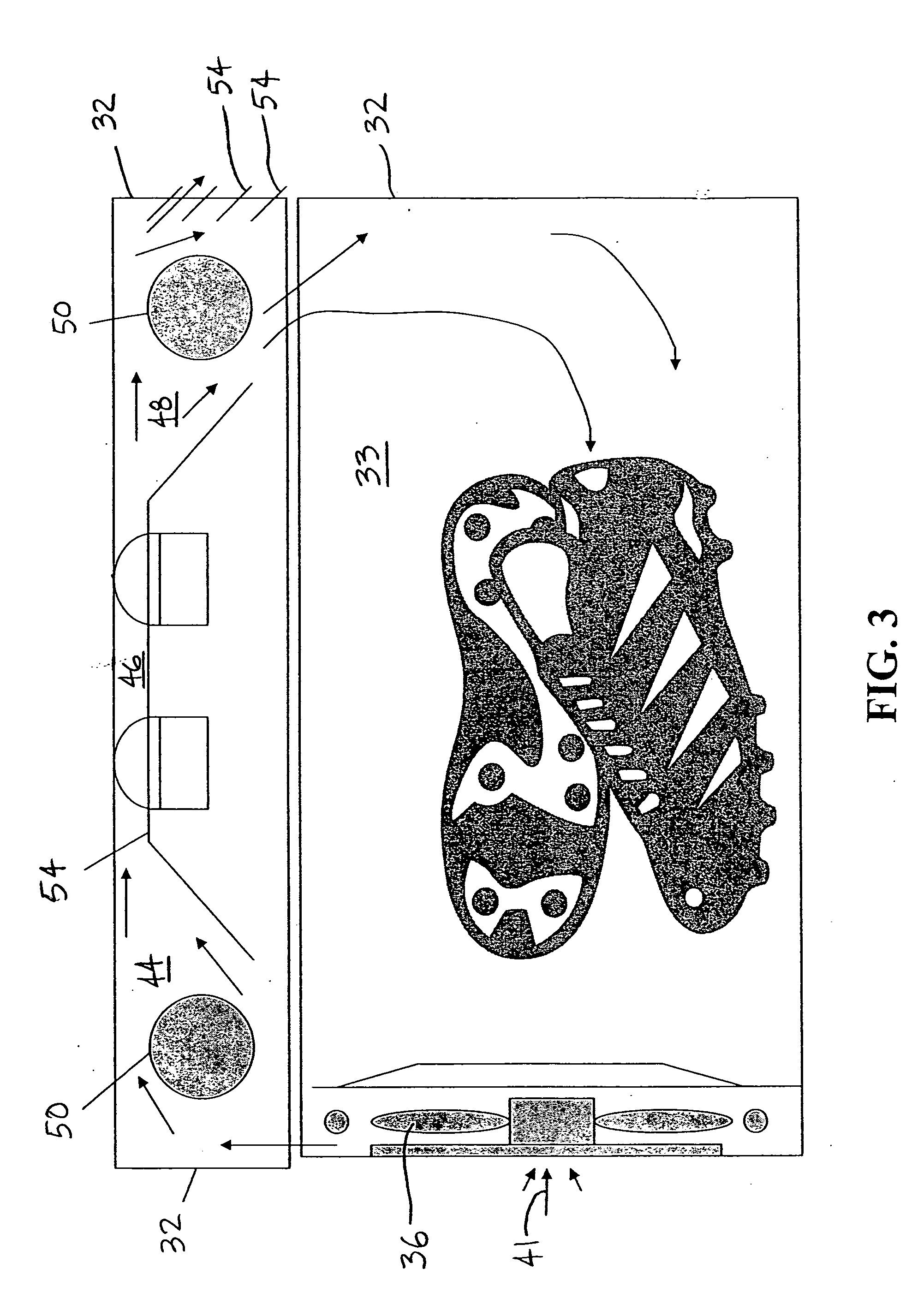

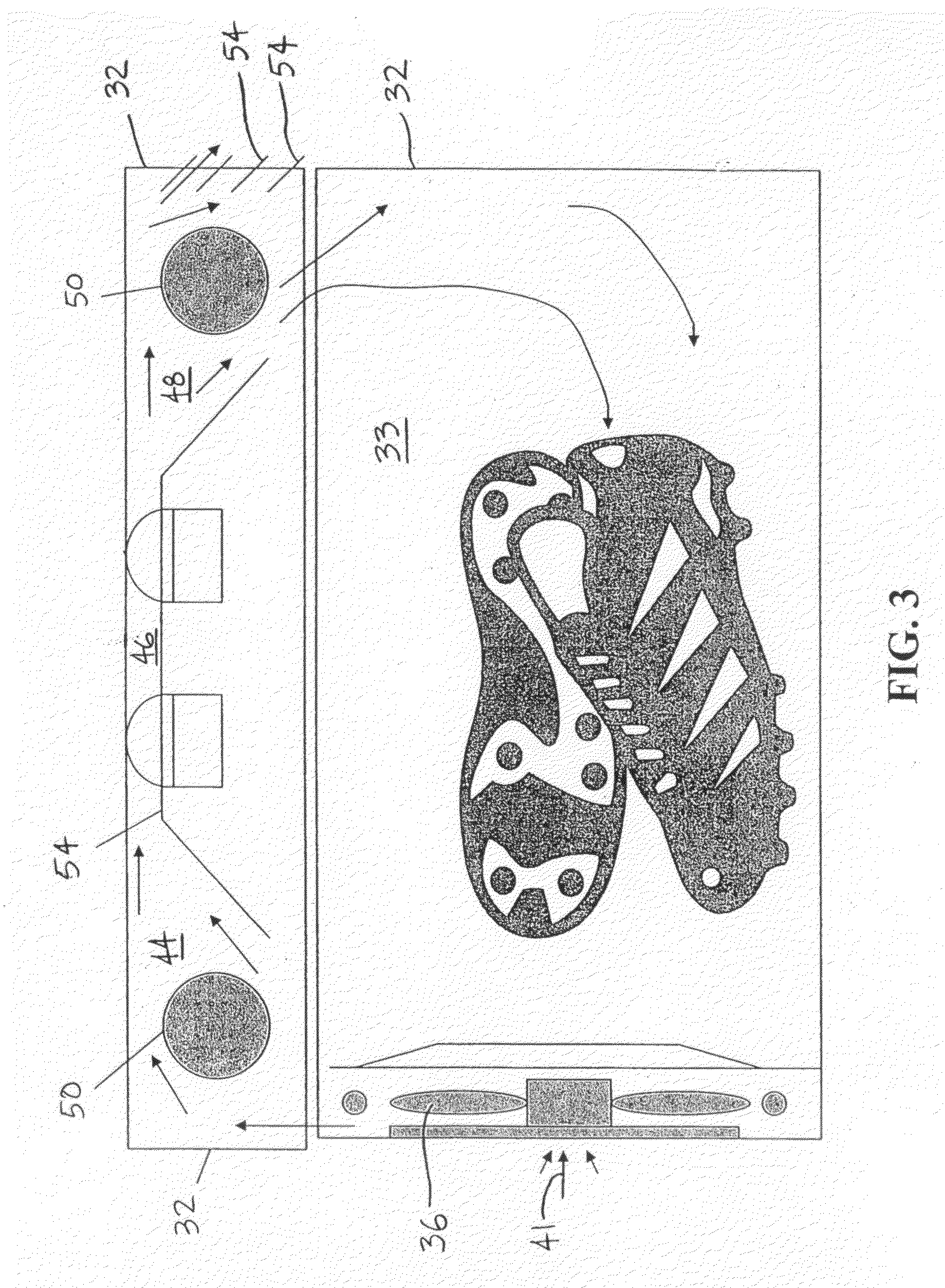

Apparatus and method for treating impurities in air and materials

InactiveUS20080118395A1Easy to cleanMaximize useMechanical apparatusGas treatmentEngineeringFruits and vegetables

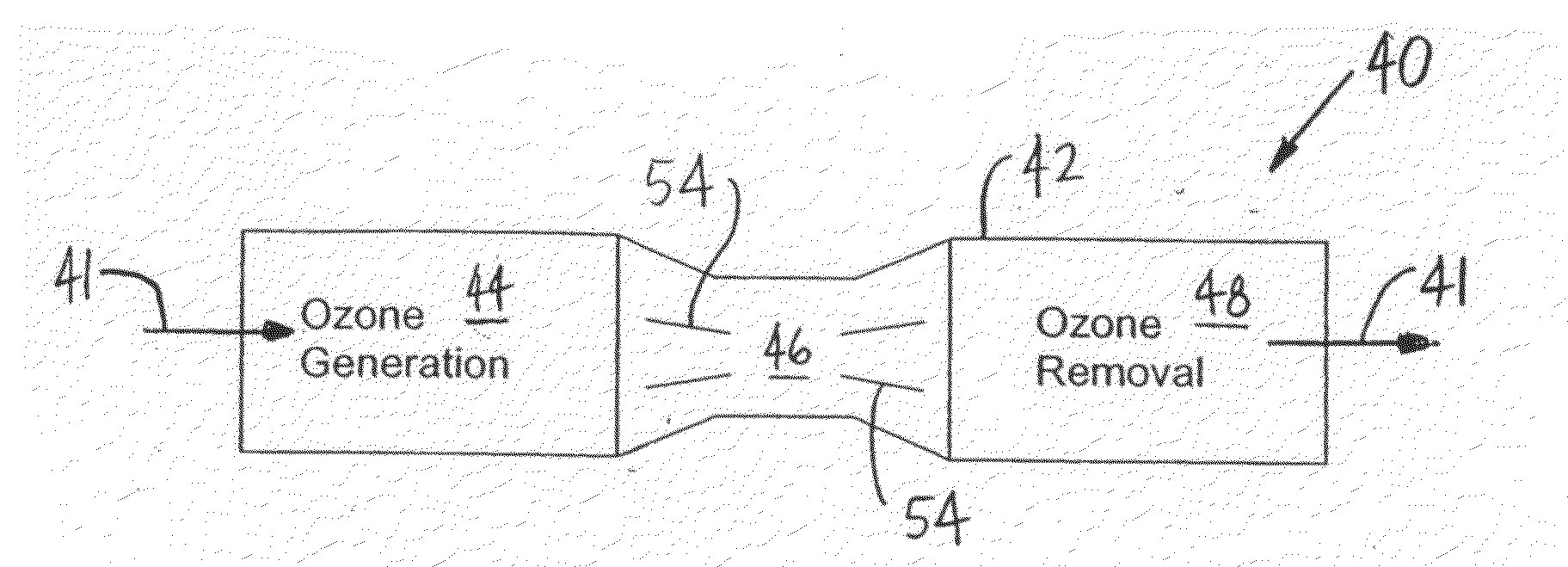

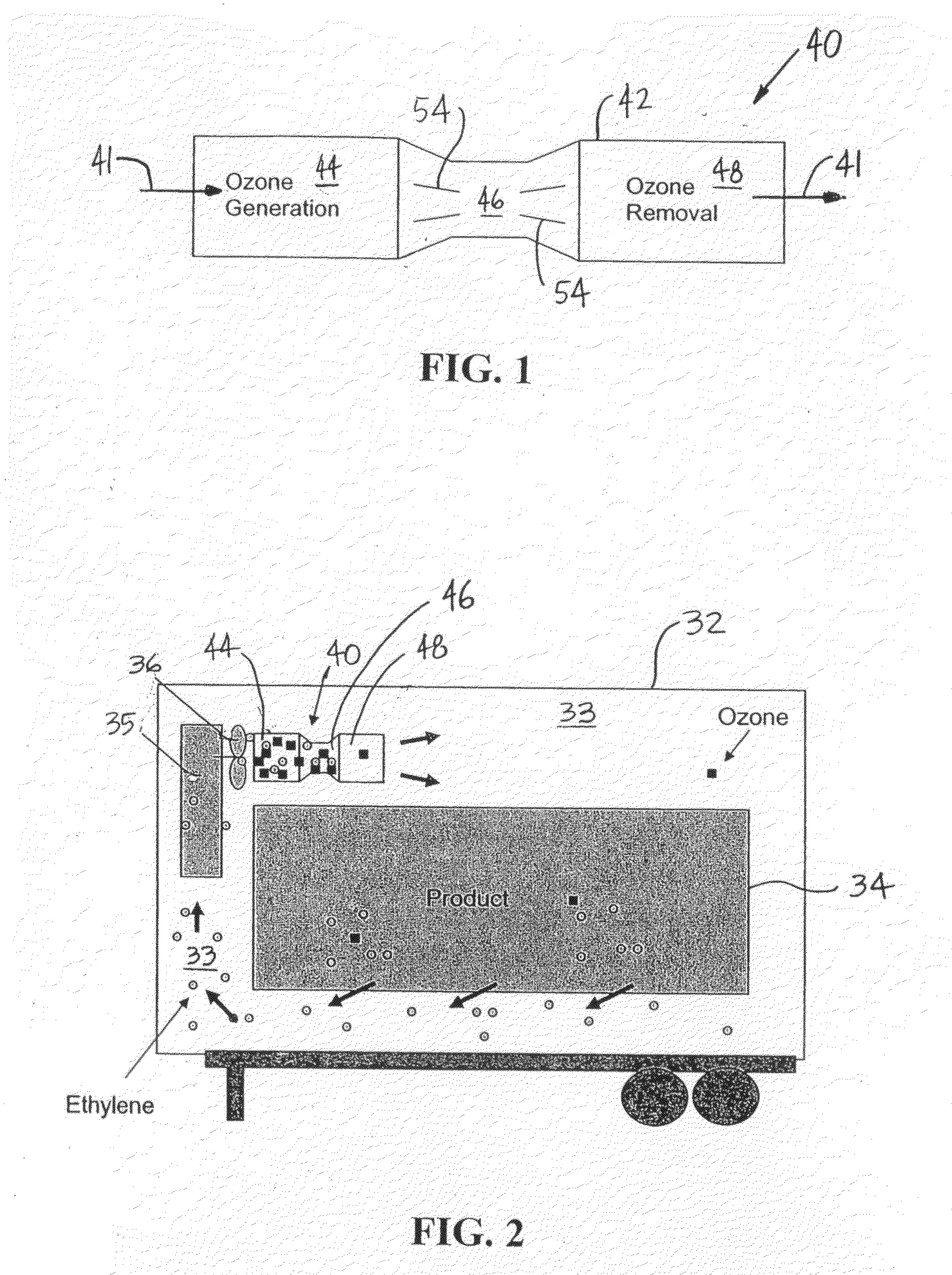

An apparatus and method for sanitizing, decontaminating, deodorizing, conditioning, drying, treating, cleaning, modifying and / or otherwise improving an atmosphere within a container. The container can be a bag or other housing for equipment, food and / or suitable material. Ozone is generated within an atmosphere that is exposed to the materials. The generated ozone is mixed with the atmosphere. At least a portion of the generated ozone is then removed from the mixed atmosphere. The apparatus and method of this invention can be used to treat contaminated sports equipment and the like, as well as to treat food storage atmospheres, such as those exposed to fresh fruits and vegetables.

Owner:BENEDEK KAREN

Method for regenerating activated carbon

InactiveCN105582904AMaximize removalReduce recycling costsOther chemical processesDispersed particle separationActivated carbonOrganic solvent

The invention relates to a method for regenerating activated carbon. The method is characterized in that the method comprises the steps of mixing a regeneration solvent having a solution temperature of 50-120 DEG C and waste activated carbon in a volume ratio of 3:1-1:3 and soaking for 10-60min; carrying out solid-liquid separation on the soaked mixture; washing the separated activated carbon to be treated with water in a volume ratio of the activated carbon to be treated to water of 1:2-1:5; and activating the washed pre-treated activated carbon with microwaves, wherein the regeneration solvent is composed of 1-10% of alkaline substance, 65-95% of organic solvent and 1-25% of water by mass percentage. The method can remove organic substances and inorganic substances adsorbed on the surface and in the micropores of the activated carbon to the maximum extent, the regenerates can be circularly utilized, the regeneration speed of the activated carbon and the quality of the regenerated carbon are improved, the regeneration cost of the activated carbon is reduced and the regeneration efficiency and the regeneration quality of the activated carbon are improved.

Owner:广州微碳科技有限公司

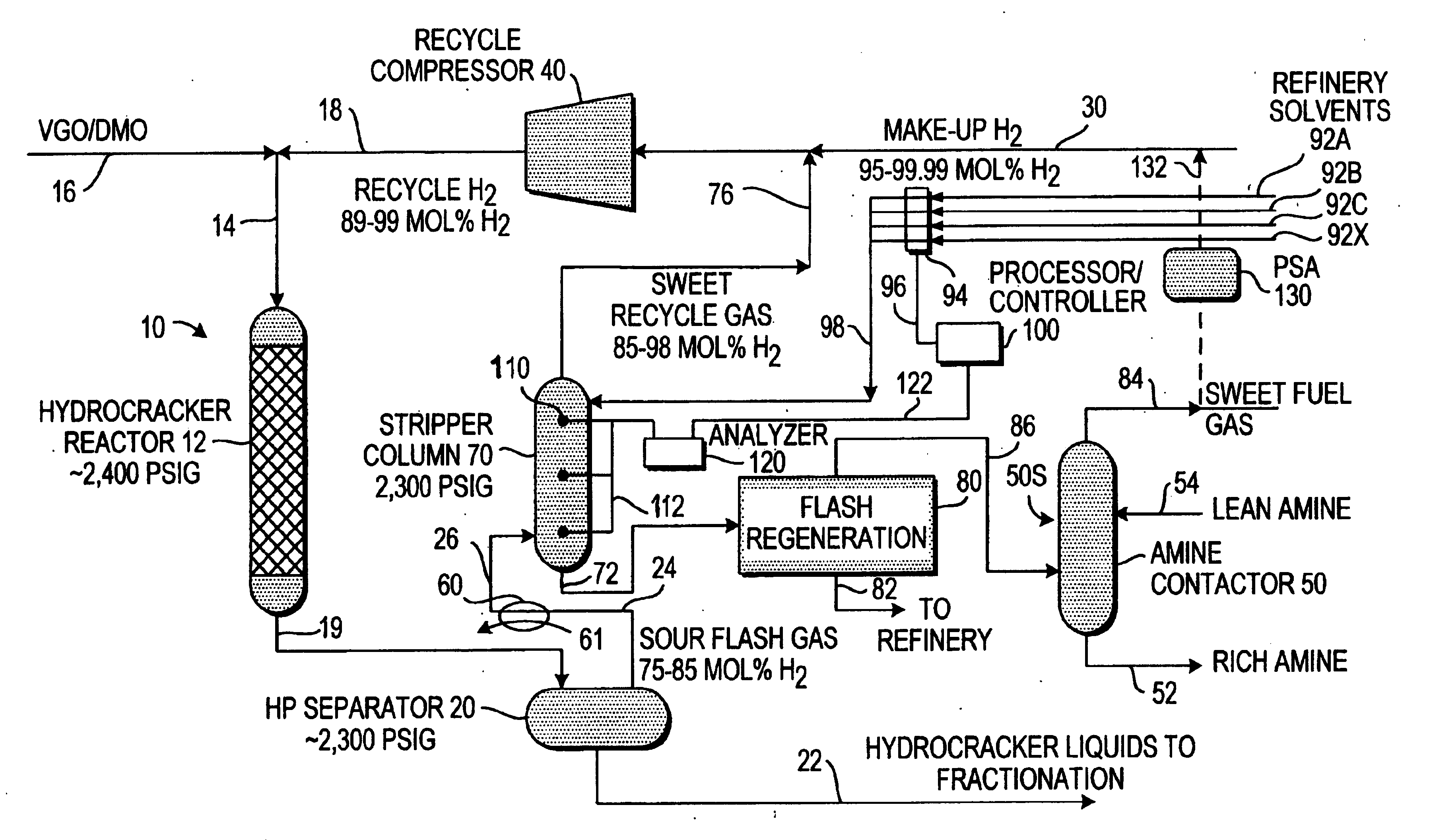

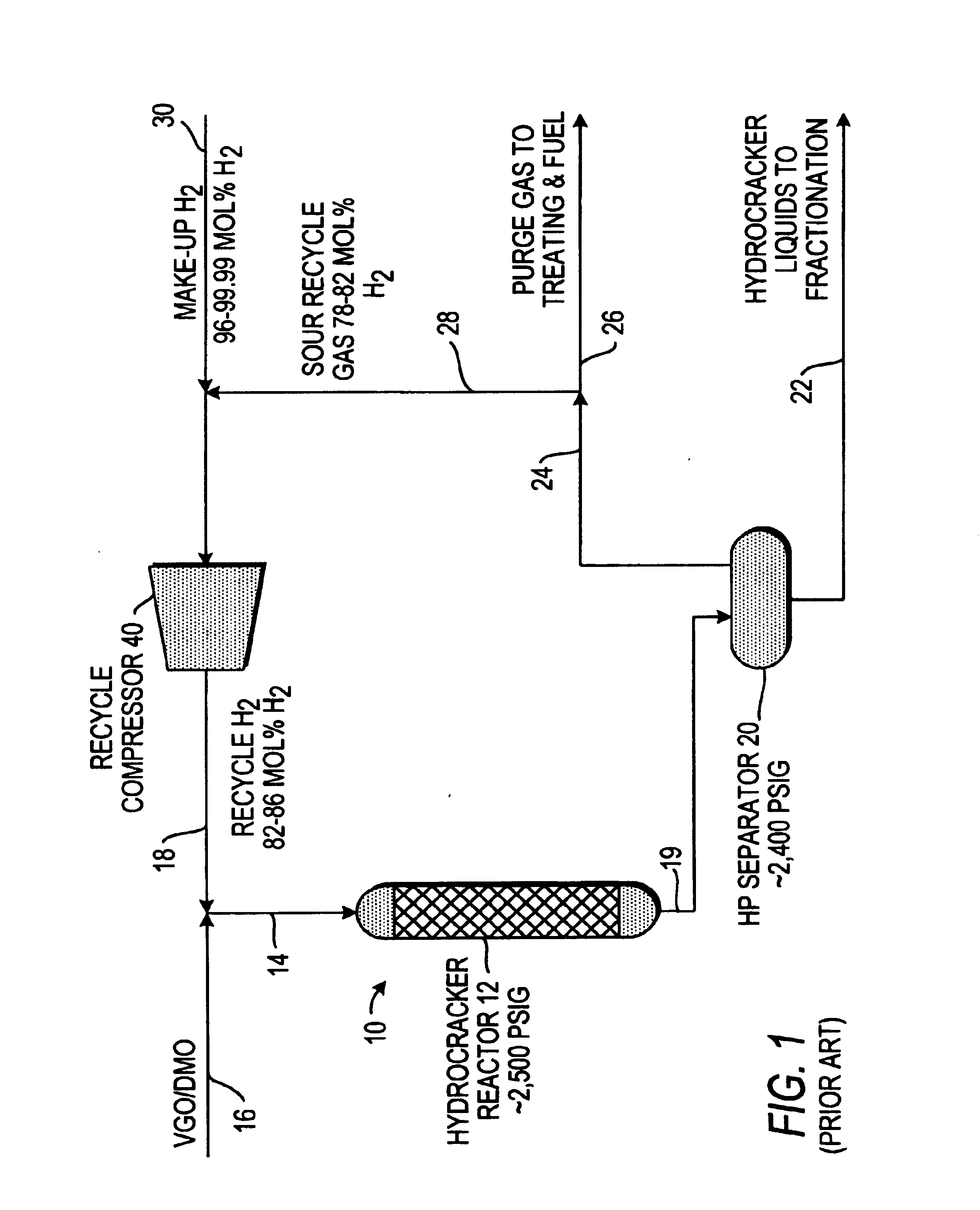

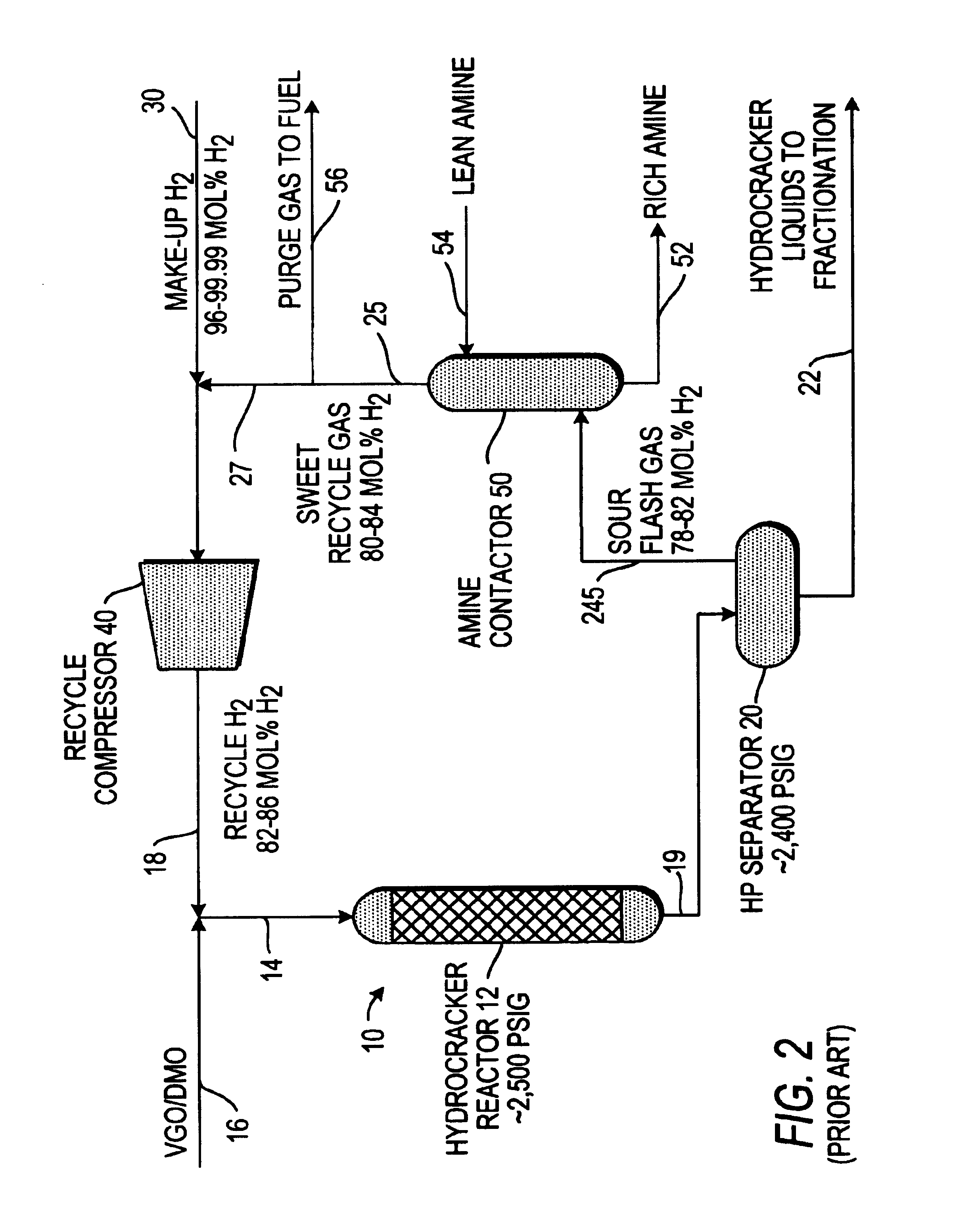

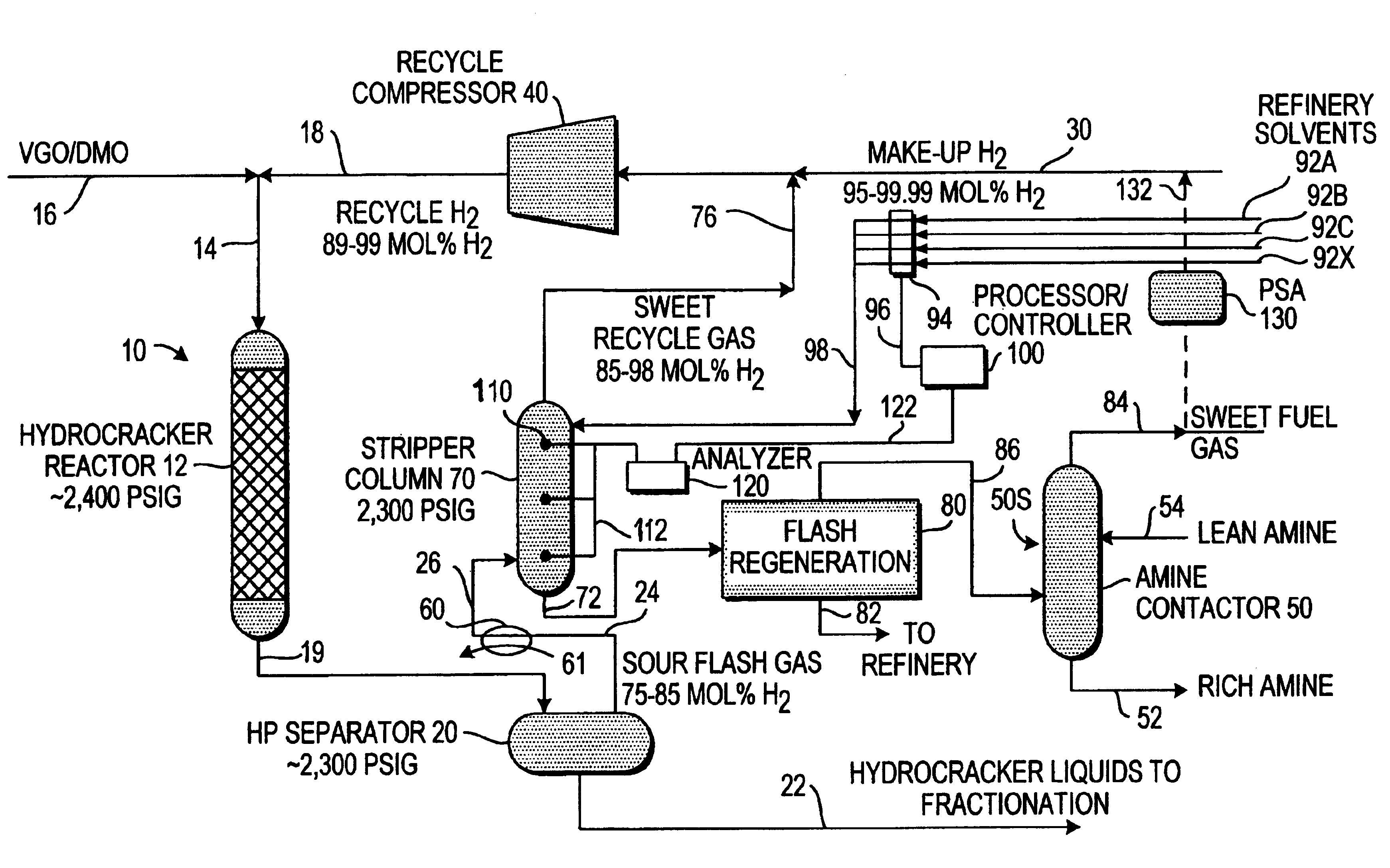

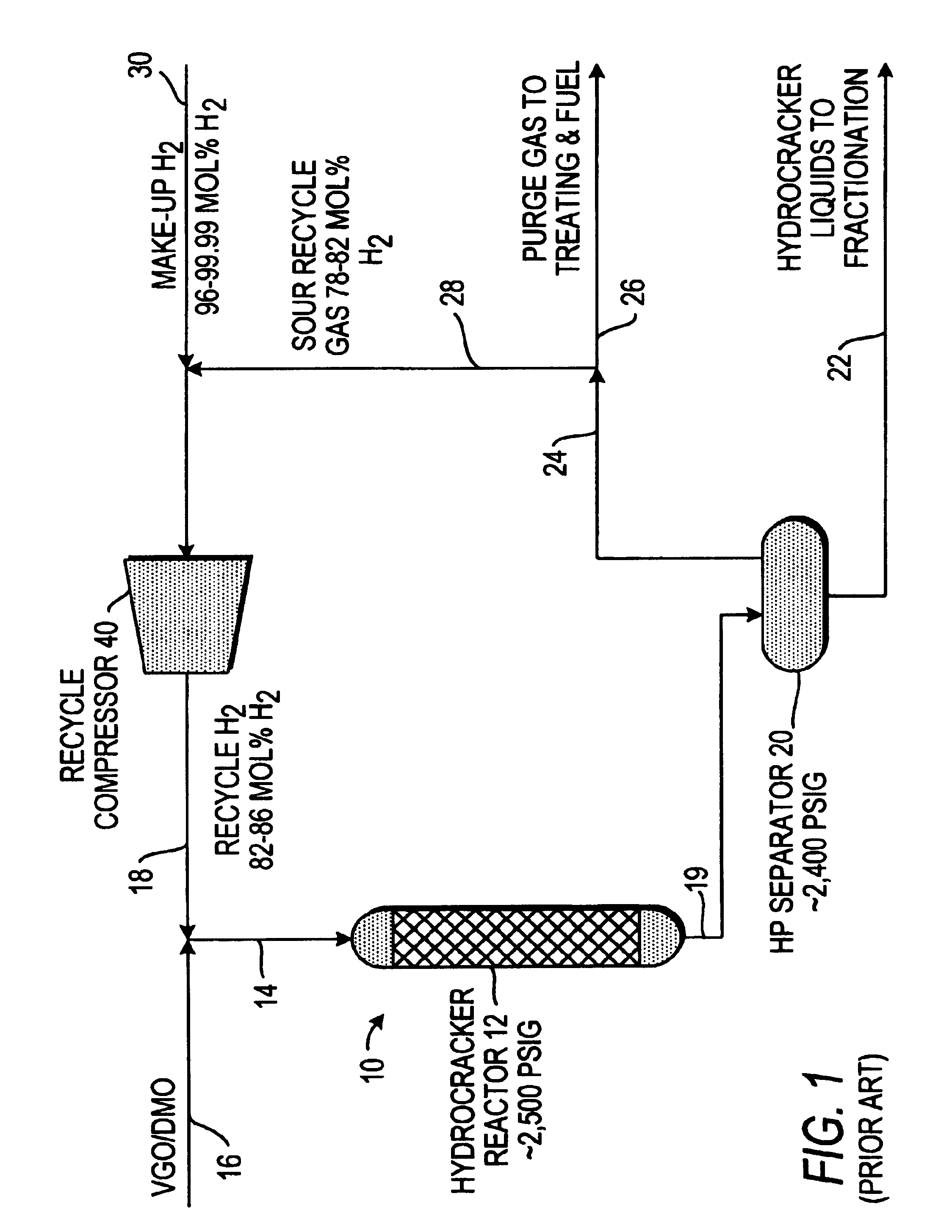

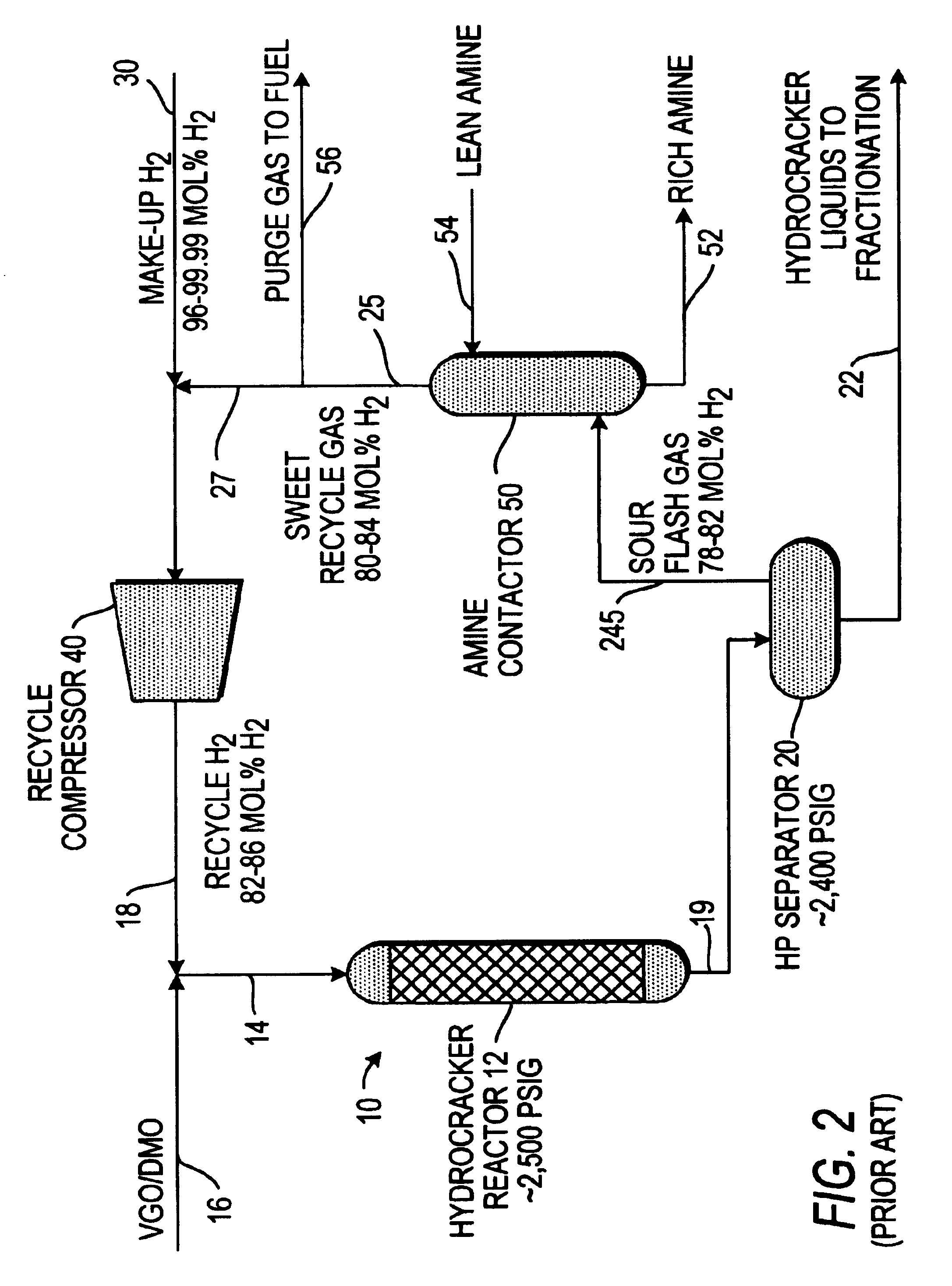

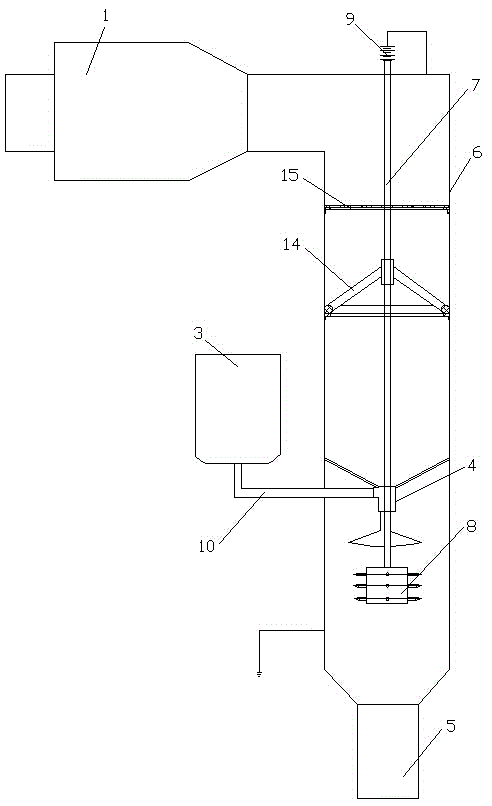

Enhanced hydrogen recovery for hydroprocessing units

ActiveUS20050188841A1Increase the concentration of hydrogenEfficiency and economy in operationSolidificationLiquefactionHydrogenControl system

A process for the recovery of high purity hydrogen for recycling to a hydroprocessing or similar unit located in an integrated refinery facility includes sampling and providing analytical information on the make-up of the hydrogen-containing feedstream entering the bottom of a stripping column and the composition of the hydrogen recycle stream at, and / or approaching the top of the stripping column to a computer-directed control system in real time for the purpose of controlling the selection and the volumetric flow rate of one or more “refinery solvents” into the column to maximize the removal of non-hydrogen gases from the feedstream and to thereby maximize the percentage of hydrogen in the recycle gas stream. The “refinery solvent” used in the stripping column is any one or more compounds that are generated as product or by-product streams in the integrated refinery facility that are readily available for diversion in the required quantities for use a solvent to absorb or strip one or more compounds from the hydrogen-containing feedstream at the integrated refinery facility. The refinery solvent is preferable subsequently flashed to remove separated compounds and returned to its original product stream.

Owner:SAUDI ARABIAN OIL CO

Reaction type VOCs absorbent

InactiveCN106563346AMaximize removalEfficient and fast dissolutionGas treatmentDispersed particle separationSodium metasilicatePotassium

The invention discloses a reaction type VOCs absorbent. The reaction type VOCs absorbent comprises the following components by mass percent: 92% to 97% of water, 0.2% to 1% of a surfactant, 0.5% to 1% of inorganic salt and 0.2% to 1% of an organic matter decomposing agent, wherein the surfactant is at least one in castor oil sodium sulfonate, sodium sulpho methyl stearate, Tween 20, Tween 80, alkyl glycoside, sodium citrate and sodium dodecyl benzene sulfonate; inorganic salt is at least one in sodium carbonate, potassium carbonate, sodium metasilicate, sodium chloride, potassium chloride and ammonium chloride; and the organic matter decomposing agent is at least one in cysteine hydrochloride, arginine, lysine, histidine, 2-imidazolidone, acethydrazide and adipic dihydrazide. The reaction type VOCs absorbent has the advantages that multiple components in VOCs can be treated at the same time, the removing efficiency for volatile organic matters is high, the organic matter decomposing agent in the components of the absorbent can degrade organic exhaust gas into CO2 and water or other micromolecules, the raw materials are wide in source, the cost is low, and follow-up treatment is simple.

Owner:千藤(南京)环保科技有限公司

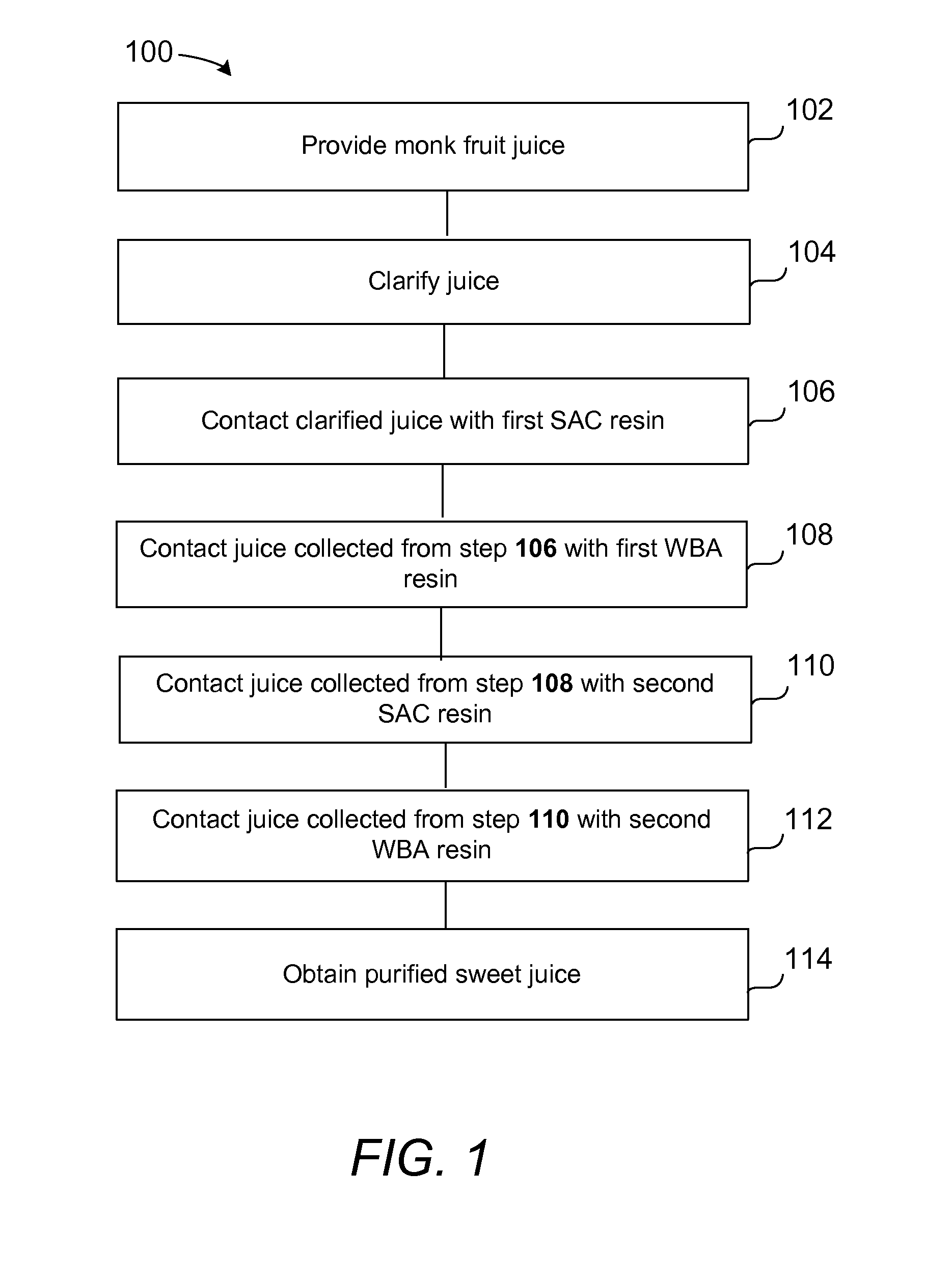

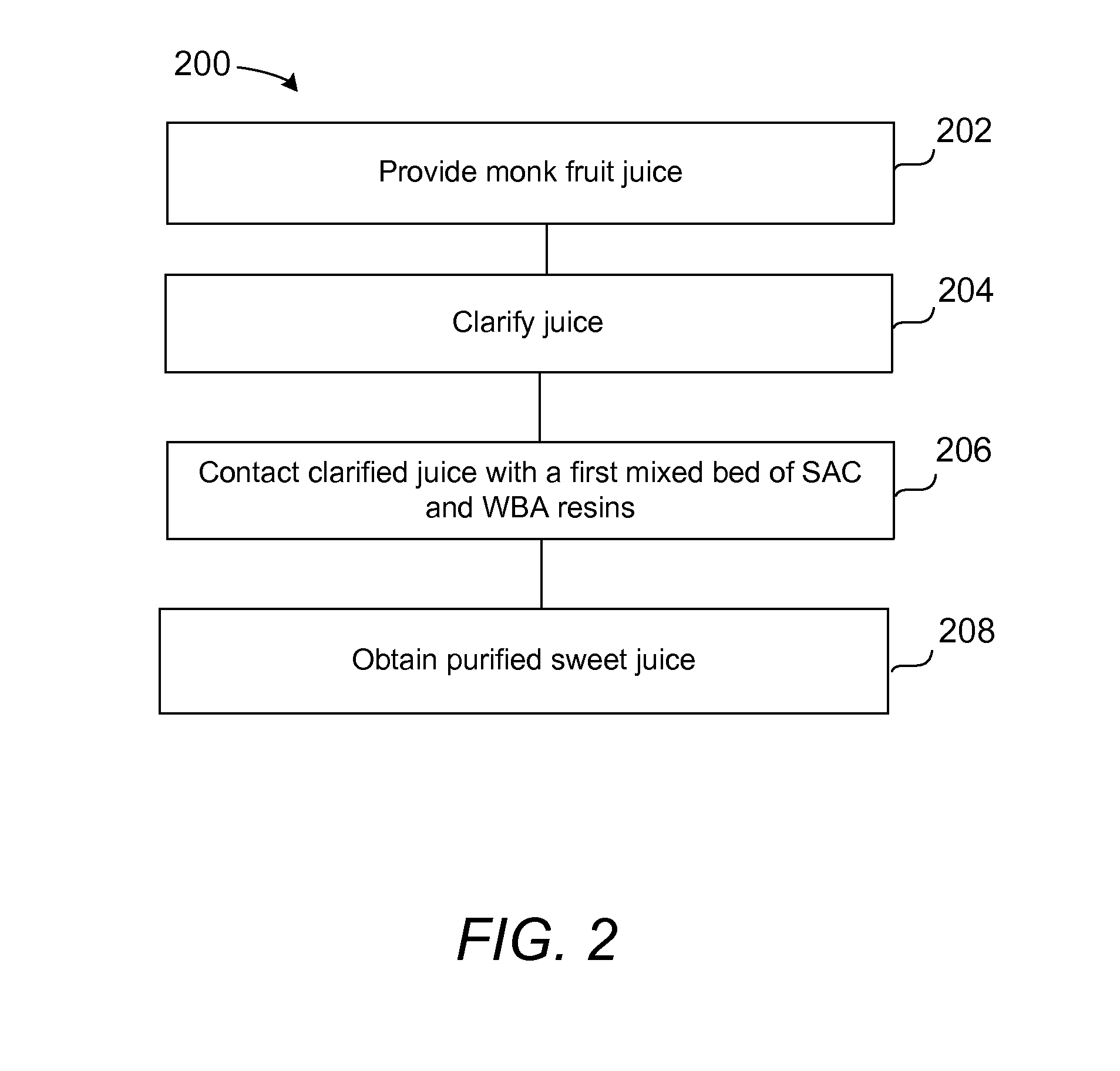

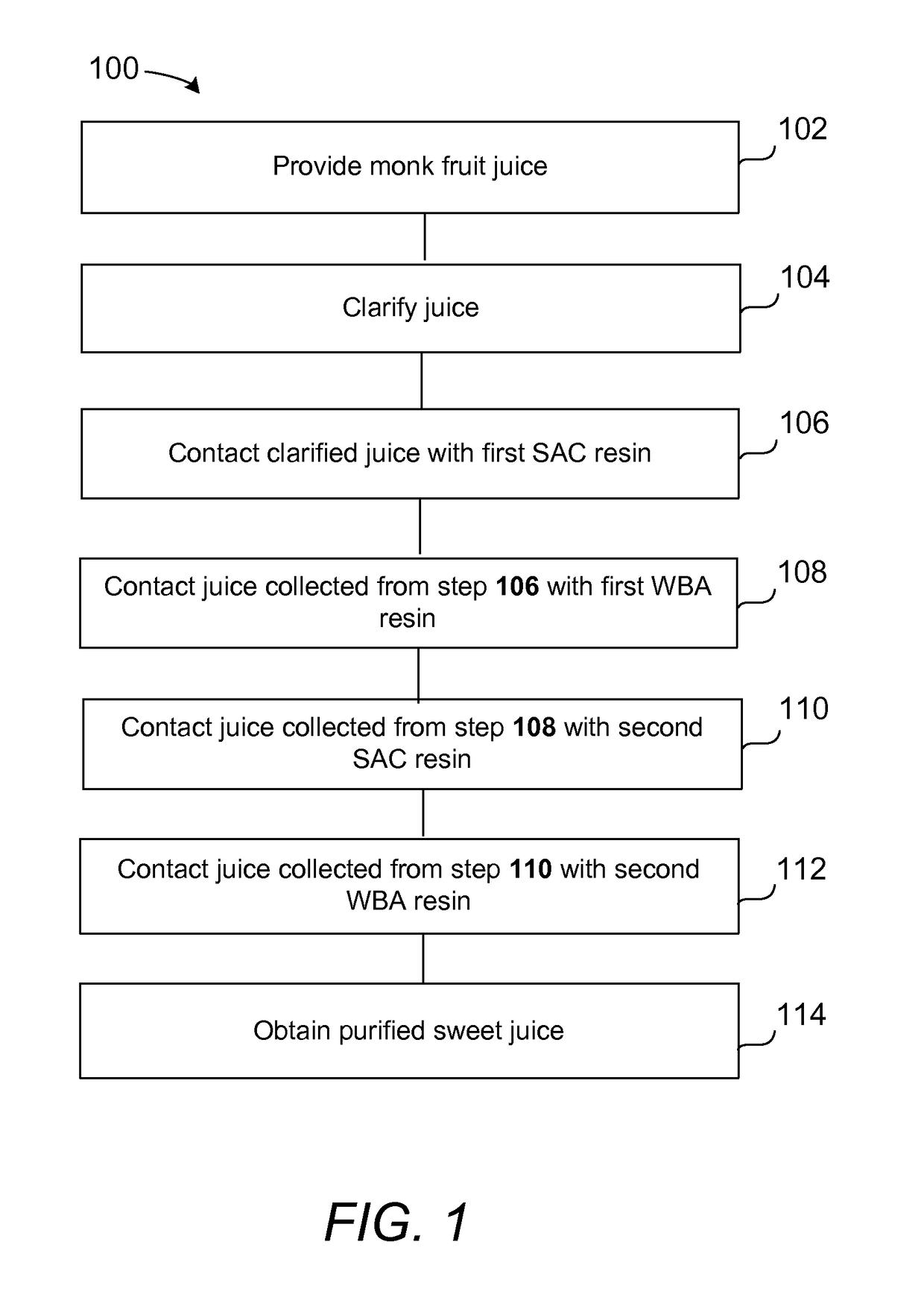

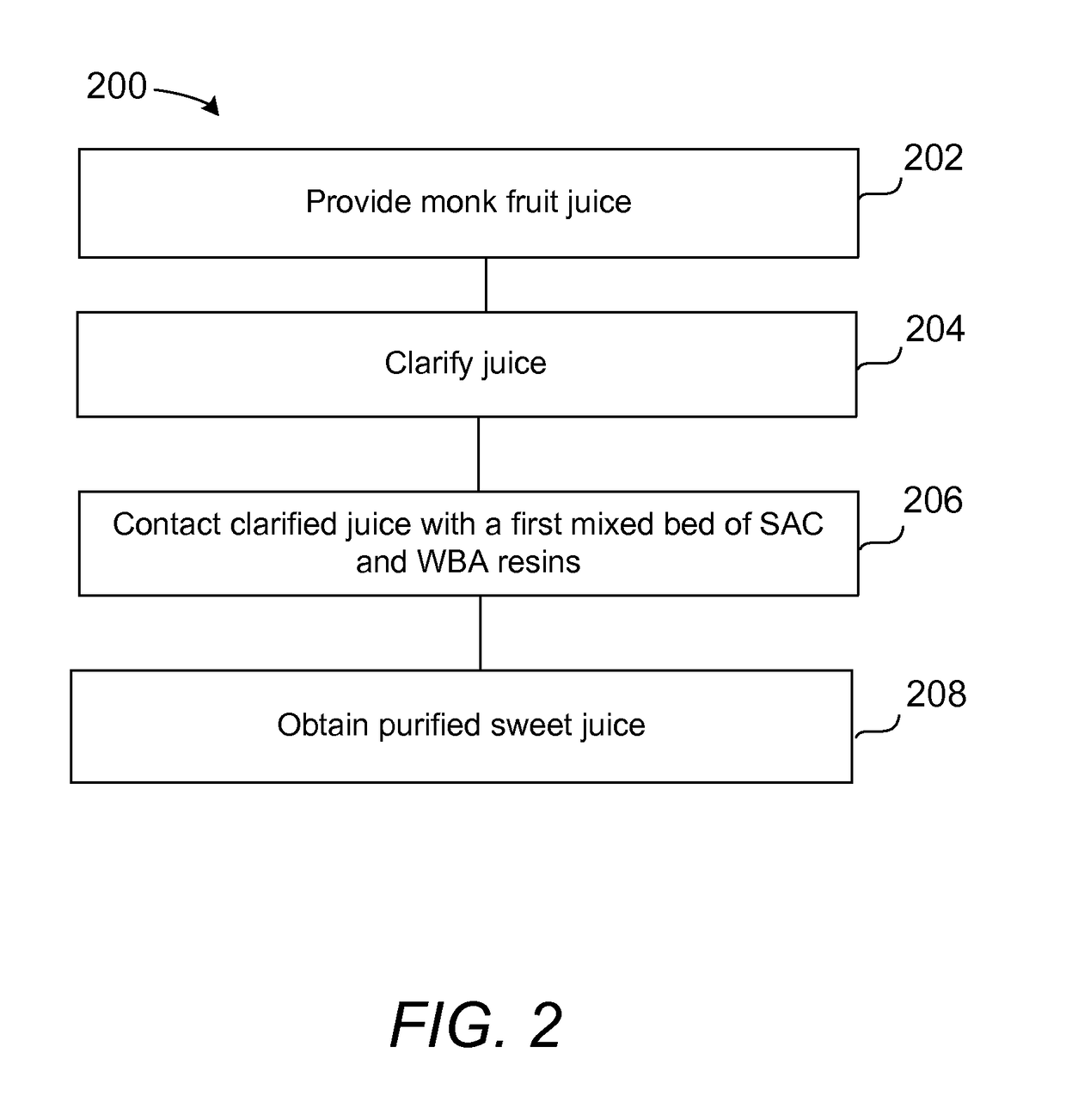

Methods of producing sweet juice compositions

InactiveUS20140044843A1Minimize absorptionMaximize removalMilk preparationAnimal feeding stuffFlavorGlycoside

The present disclosure relates to methods of producing a sweet juice composition from monk fruit and other fruit of the Cucurbitaceae family containing mogroside V and other terpene glycosides. The methods employ a cation exchange resin and an anion exchange resin to obtain a sweet juice composition with a clean flavor. The sweet juice composition can be used in a food, beverage, pharmaceutical or dietary supplement product.

Owner:GUILIN GFS MONK FRUIT CORP

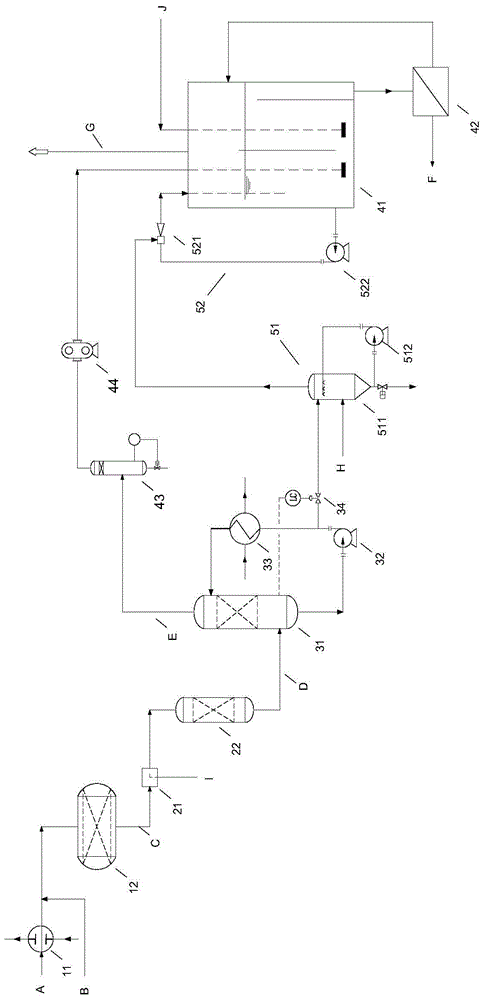

Claus tail gas treatment system and treatment method

The invention provides a Claus tail gas treatment system. The system comprises a hydrogenation unit, a fast cooling unit, a desulfurization unit, an optional hydrolysis unit and an optional liquid sulfur degassing gas supply unit. The invention further provides a Claus tail gas treatment method. According to the tail gas treatment system and treatment method provided by the invention, the sulfur removal rate can be greater than 99.99%; H2S concentration of exhaust gas emitted into the atmosphere is less than 10 ppm, and is, when converted into the SO2 concentration, less than 50 mg / m3; the removal rate and emission concentration can meet the current highest emission limit standard. Furthermore, the system and method have the advantages of: being environmentally-friendly, stable and reliable, less in investment and low in operating cost.

Owner:美景(北京)环保科技有限公司

Methods of producing sweet juice compositions

The present disclosure relates to methods of producing a sweet juice composition from monk fruit and other fruit of the Cucurbitaceae family containing mogroside V and other terpene glycosides. The methods employ a cation exchange resin and an anion exchange resin to obtain a sweet juice composition with a clean flavor. The sweet juice composition can be used in a food, beverage, pharmaceutical or dietary supplement product.

Owner:GUILIN GFS MONK FRUIT CORP

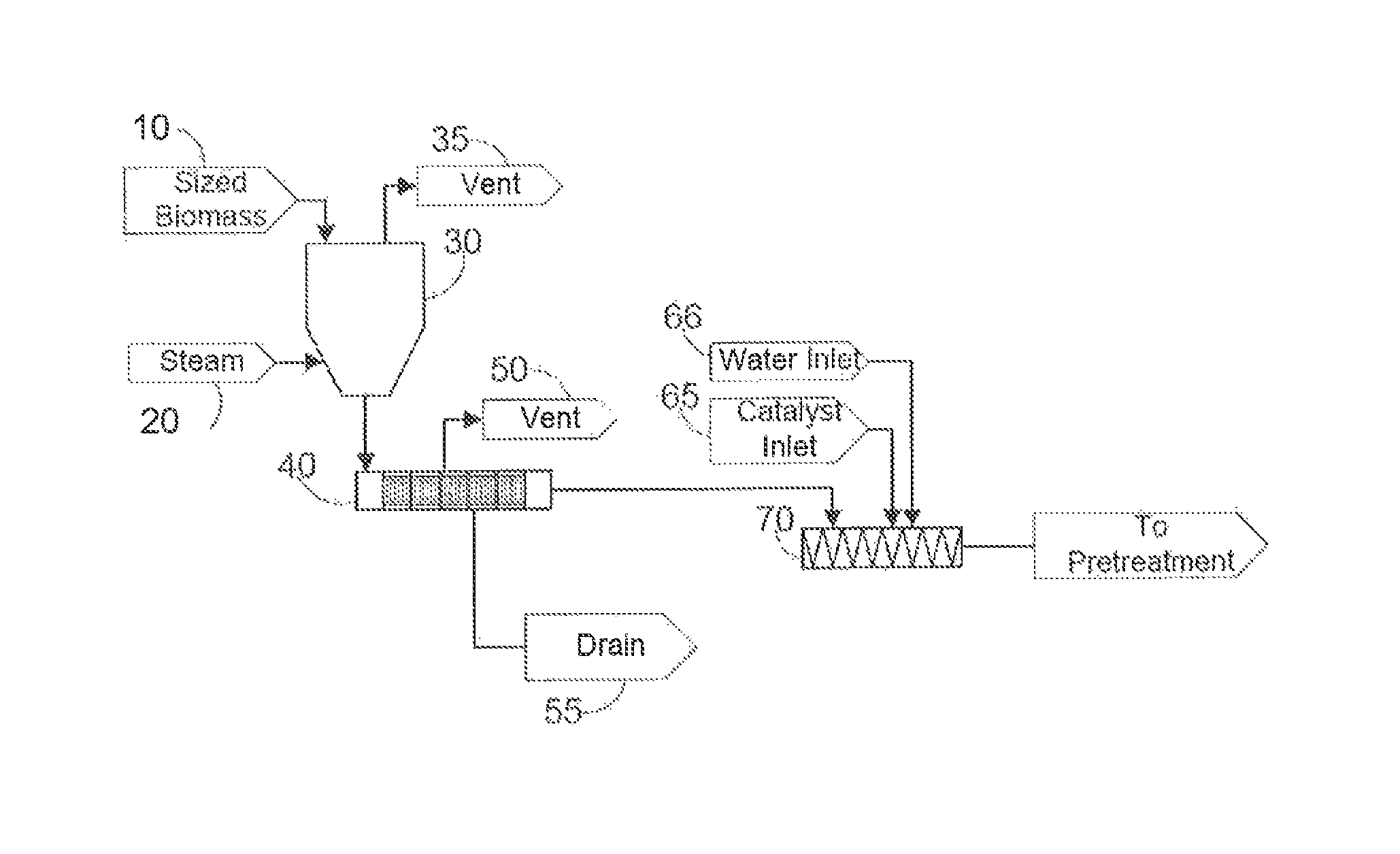

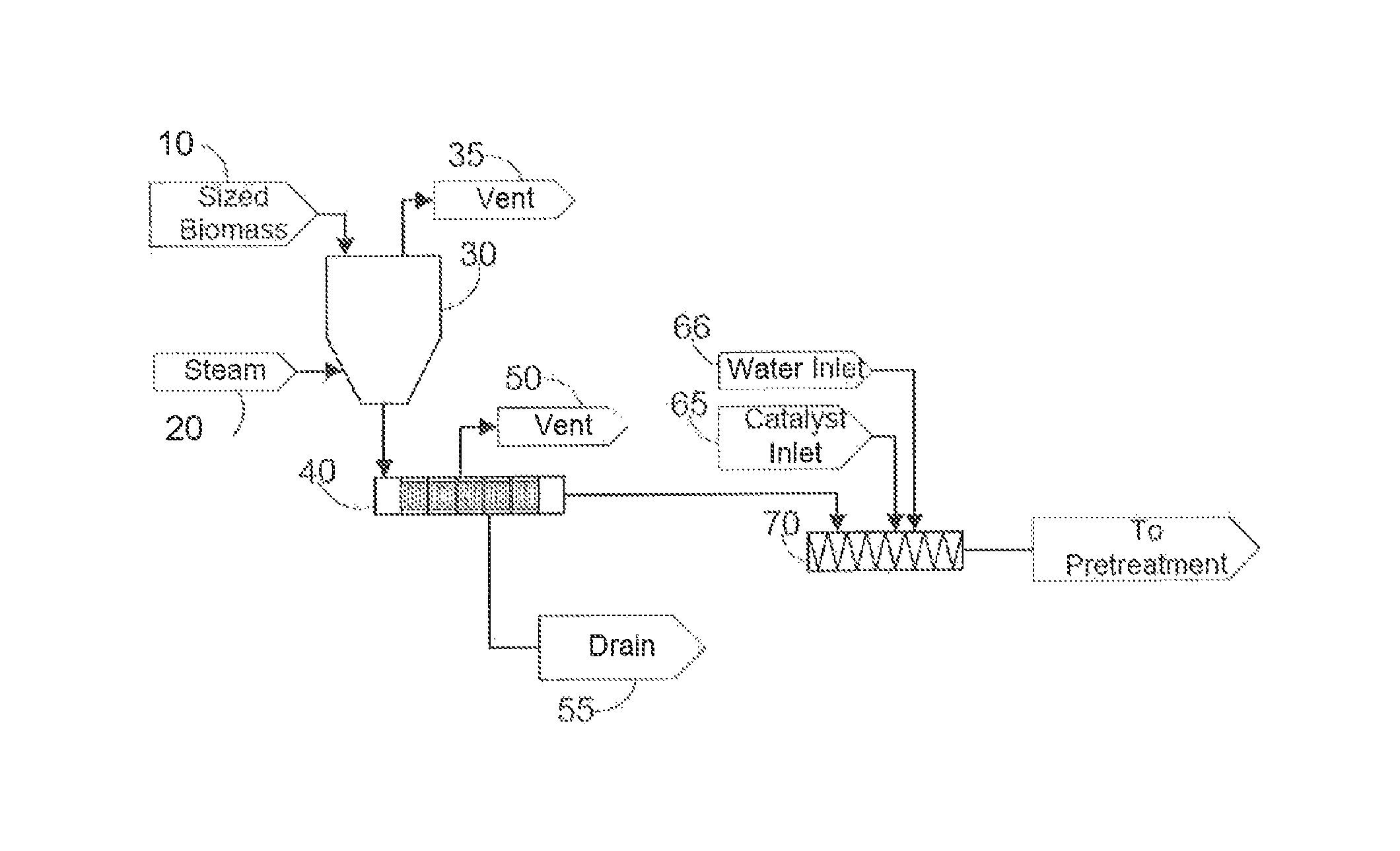

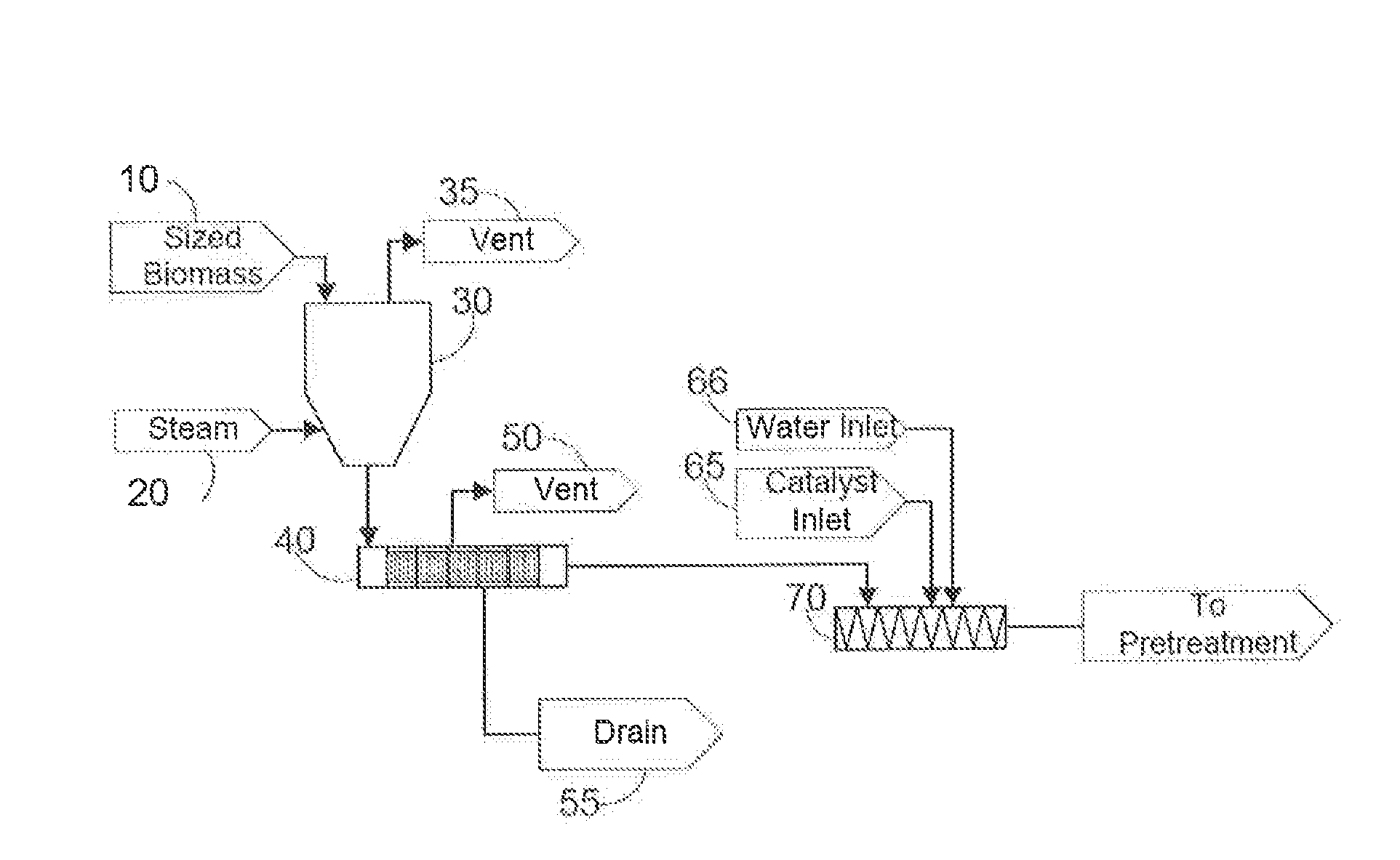

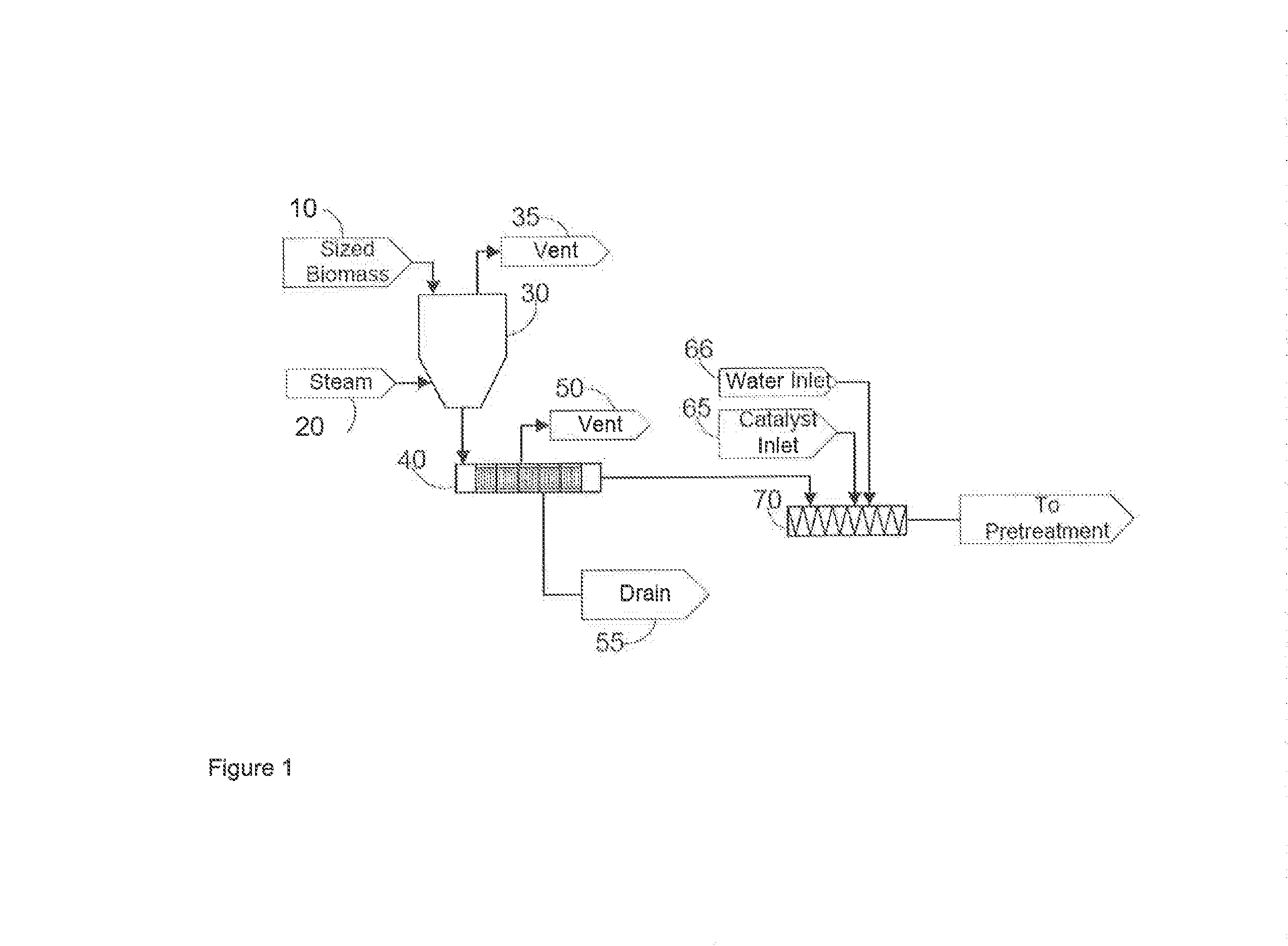

Conditioning of biomass for improved C5/C6 sugar release prior to fermentation

InactiveUS9150936B2High reactivityShorten the hydrolysis timeBiofuelsFermentationLignocellulosic biomassSugar

Disclosed is an improvement in a conventional process for C5 and C6 sugar recovery from lignocellulosic biomass for fermentation to ethanol, which process including the conventional steps of pretreatment of the biomass with steam at elevated temperature and pressure, collection of C5 sugars from hemicellulose breakdown, cellulose hydrolysis and collection of C6 sugars from cellulose breakdown. The improvement includes conditioning of the biomass prior to the pretreatment step by heating the biomass with steam for a time period between 5 minutes to 60 minutes to achieve a steam treated biomass having a temperature of about 80 to 100° C.; and adjusting a moisture content of the steam treated biomass to about 45% to 80%. An increased recovery of C5 and C6 sugars is achieved compared to the conventional process.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

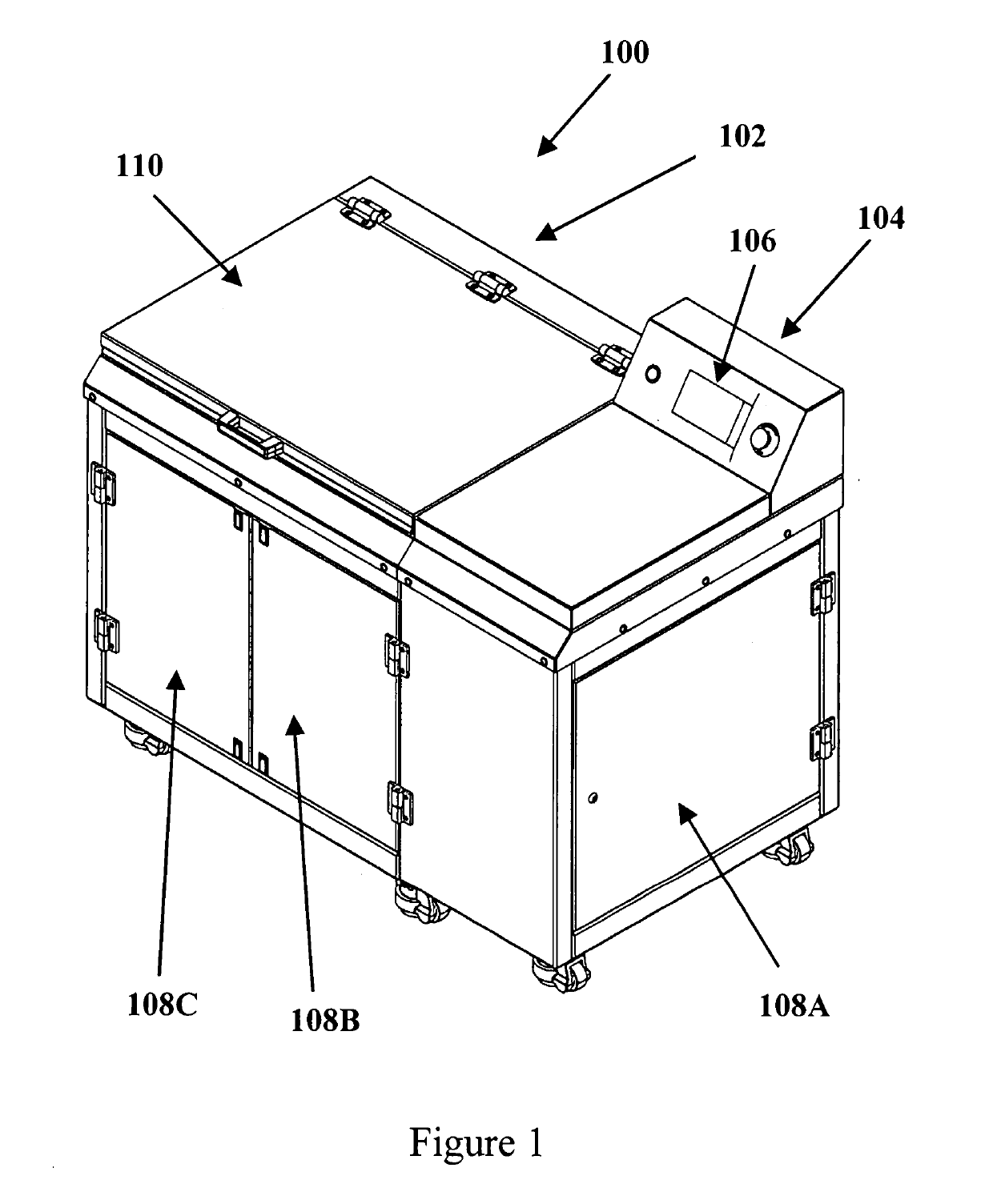

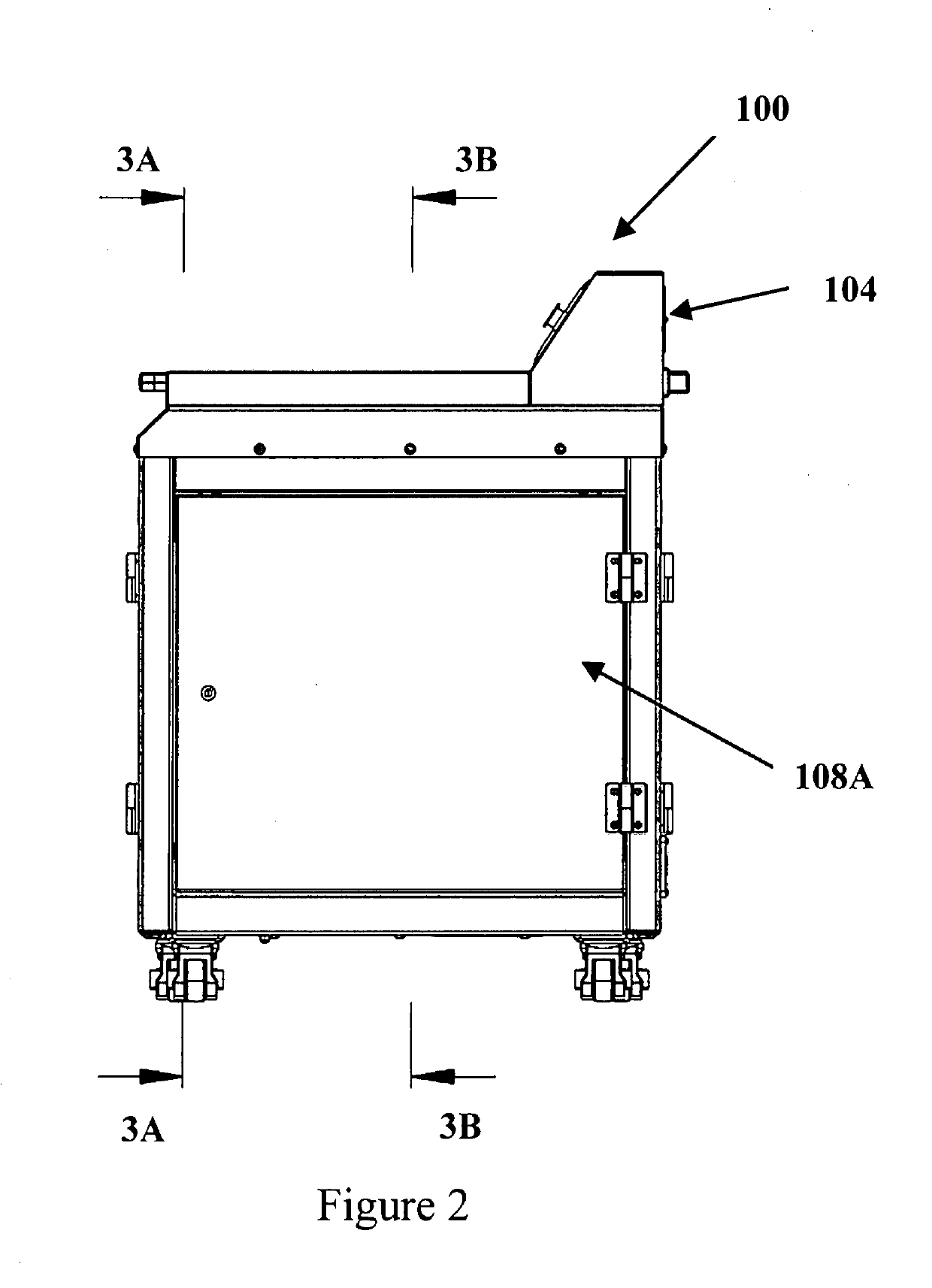

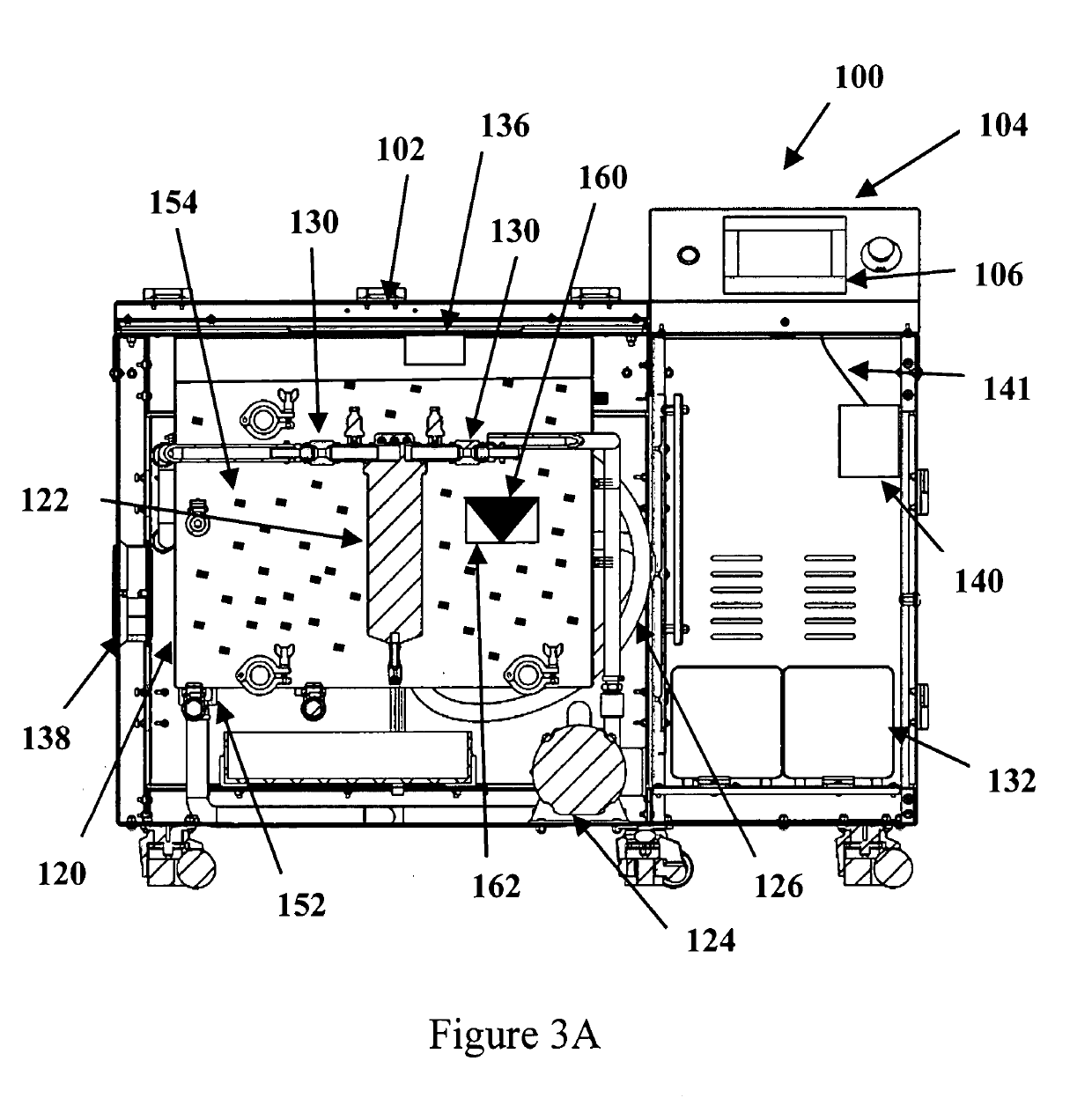

Self-Modifying Agitation Process And Apparatus For Support Removal In Additive Manufacturing And 3D Printed Material

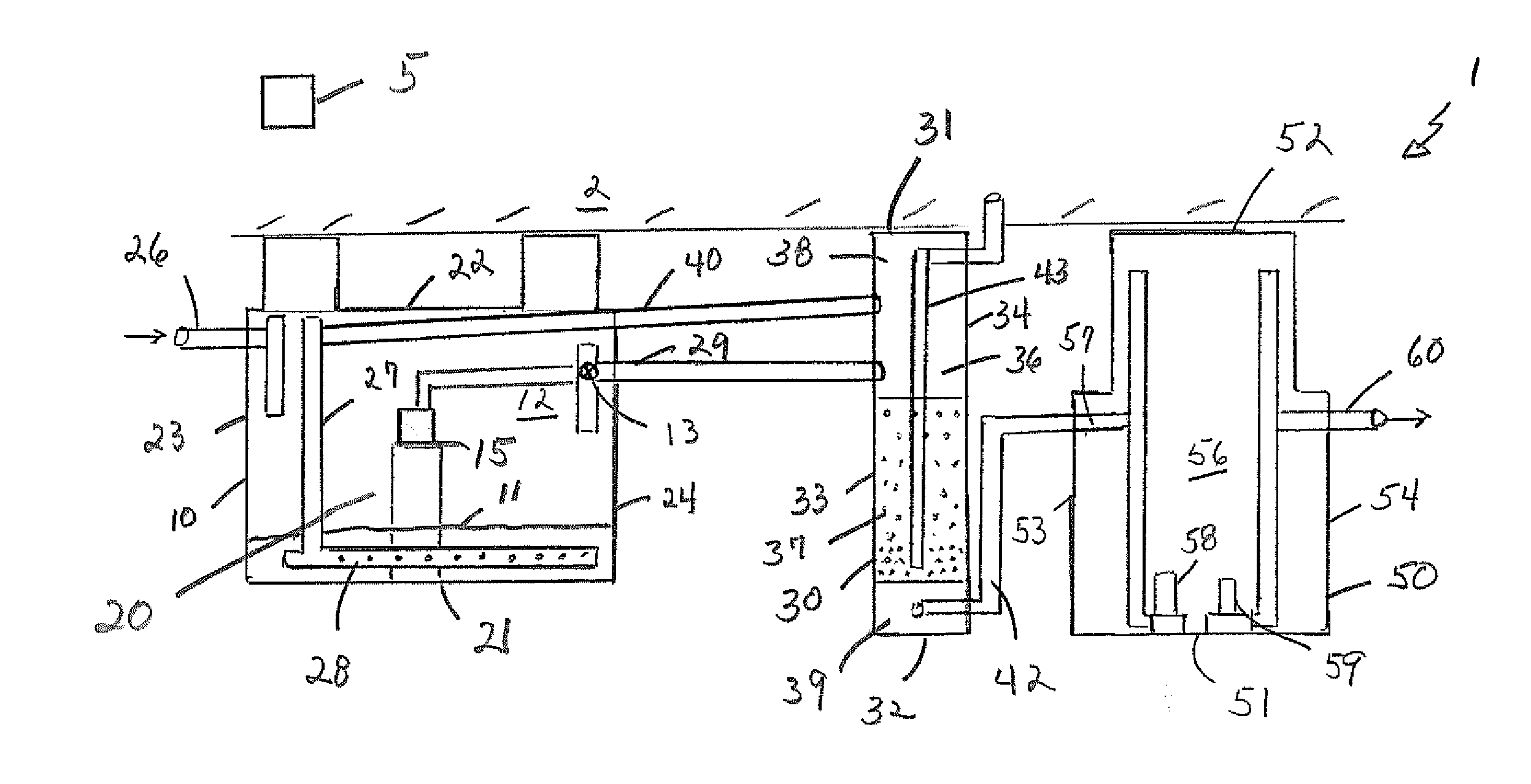

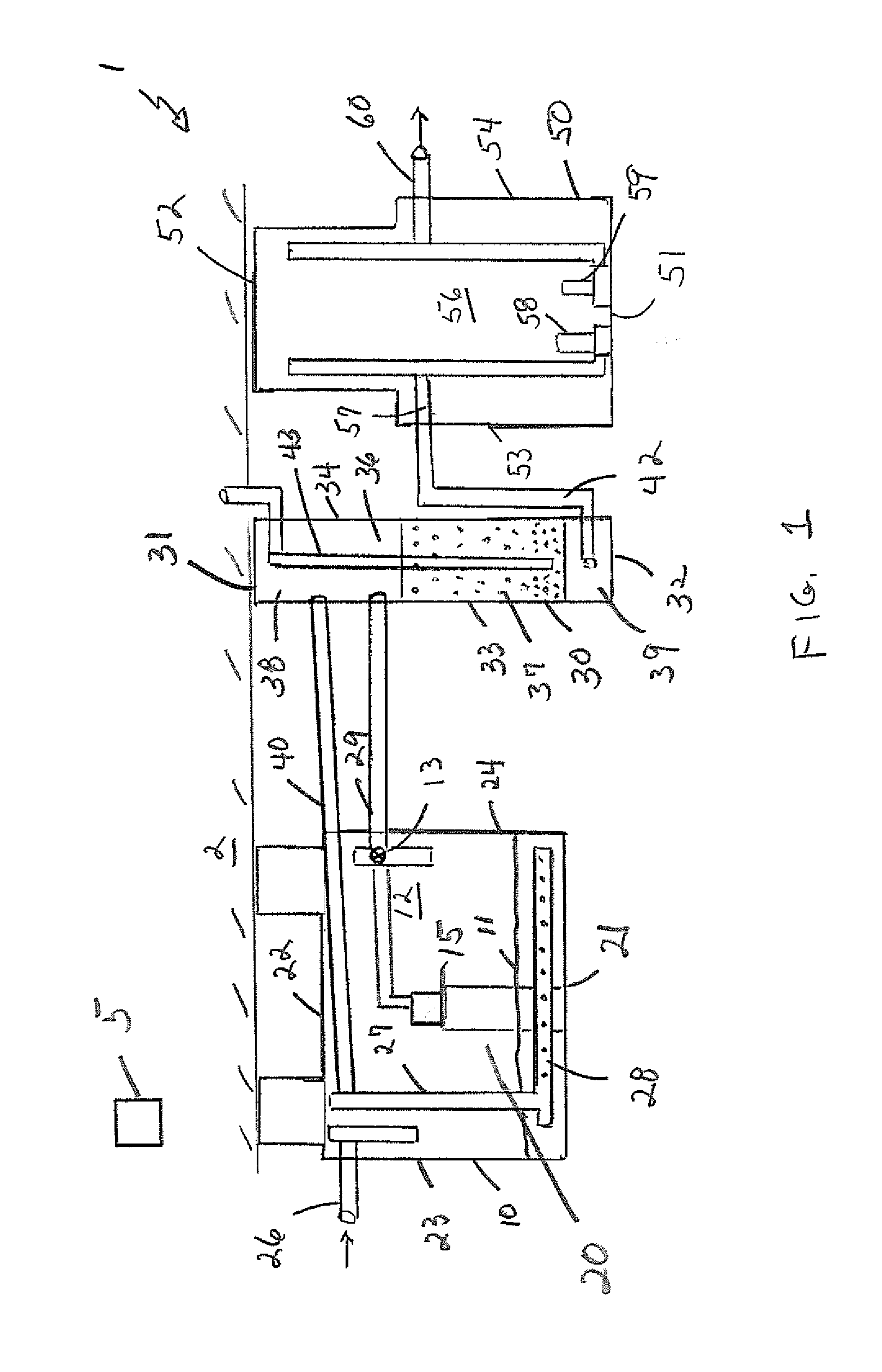

ActiveUS20190270248A1Damage limitationEnhance support removalShaking/oscillating/vibrating mixersTransportation and packagingSupport removalSonification

A process for support material removal for 3D printed parts wherein the part is placed in a media filled tank and support removal is optimized in a multi-parameter system through an artificial intelligence process which may include, but is not limited to, the use of historical data, parametric testing data, normal support removal data, and outputs from other support removal AI models to generate optimally efficient use of each parameter in terms of pulse repetition interval (PRI) and cycle time as defined by pulse width (PW). The input parameters may include heat, circulation, ultrasound and chemical reaction, which are used in sequence and / or in parallel, to optimize efficiency of support removal. Sequentially and / or in parallel, heat, pump circulation and ultrasound may vary in application or intensity. Selection of means of agitation depends on monitored feedback from the support removal tank and application of a statistically dynamic rule based system (SDRBS).

Owner:POSTPROCESS TECH INC

Enhanced hydrogen recovery for hydroprocessing units

Owner:SAUDI ARABIAN OIL CO

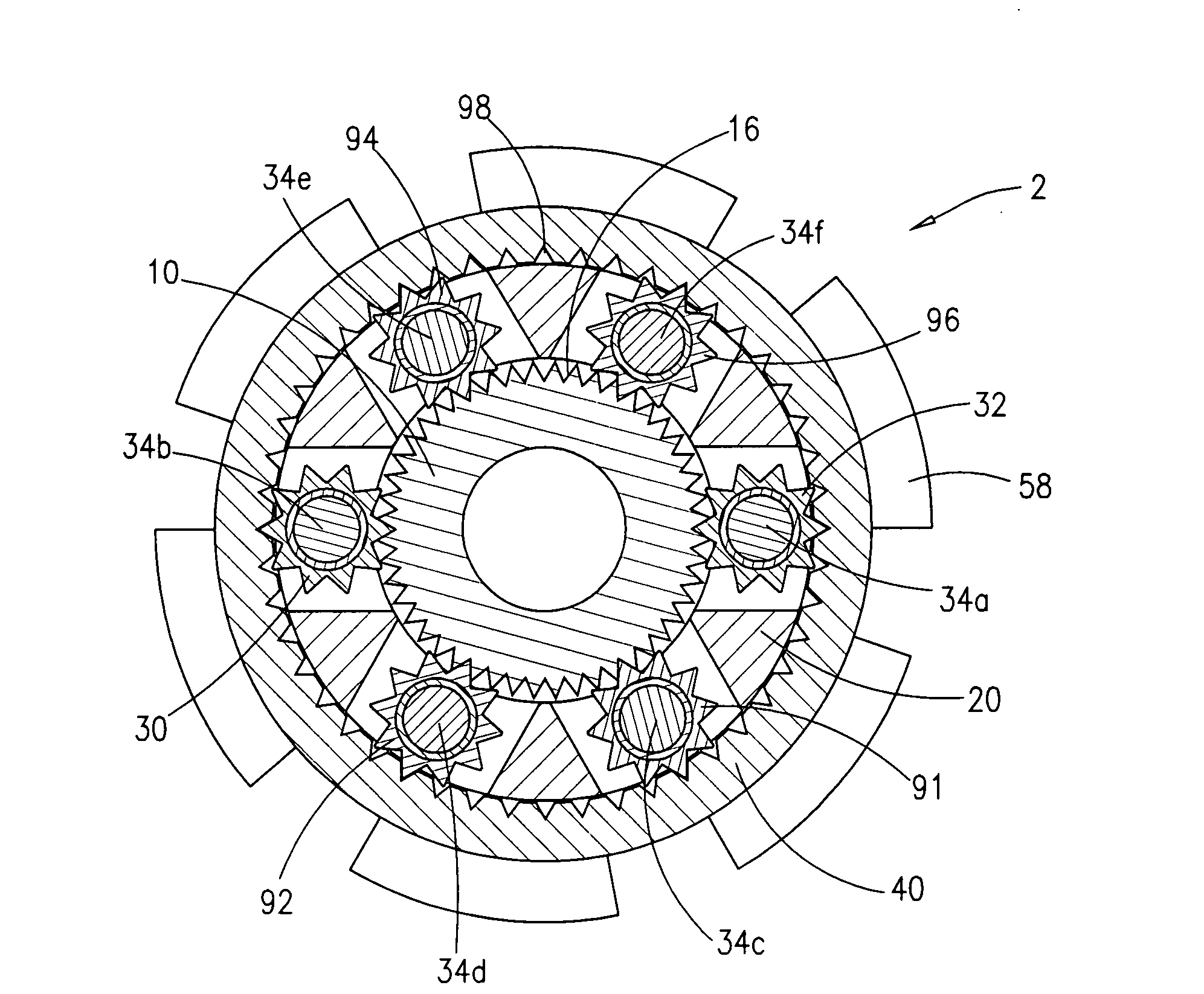

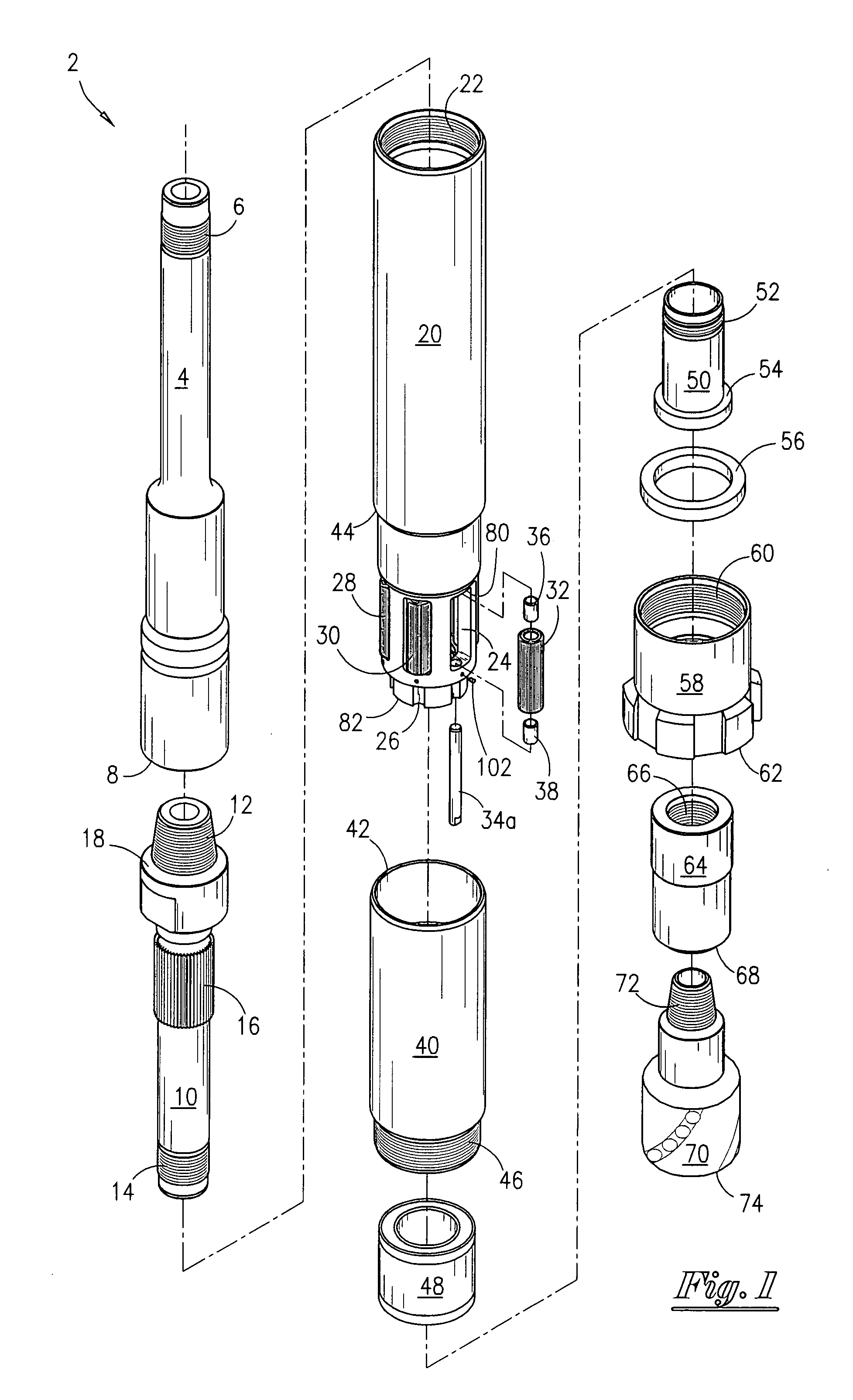

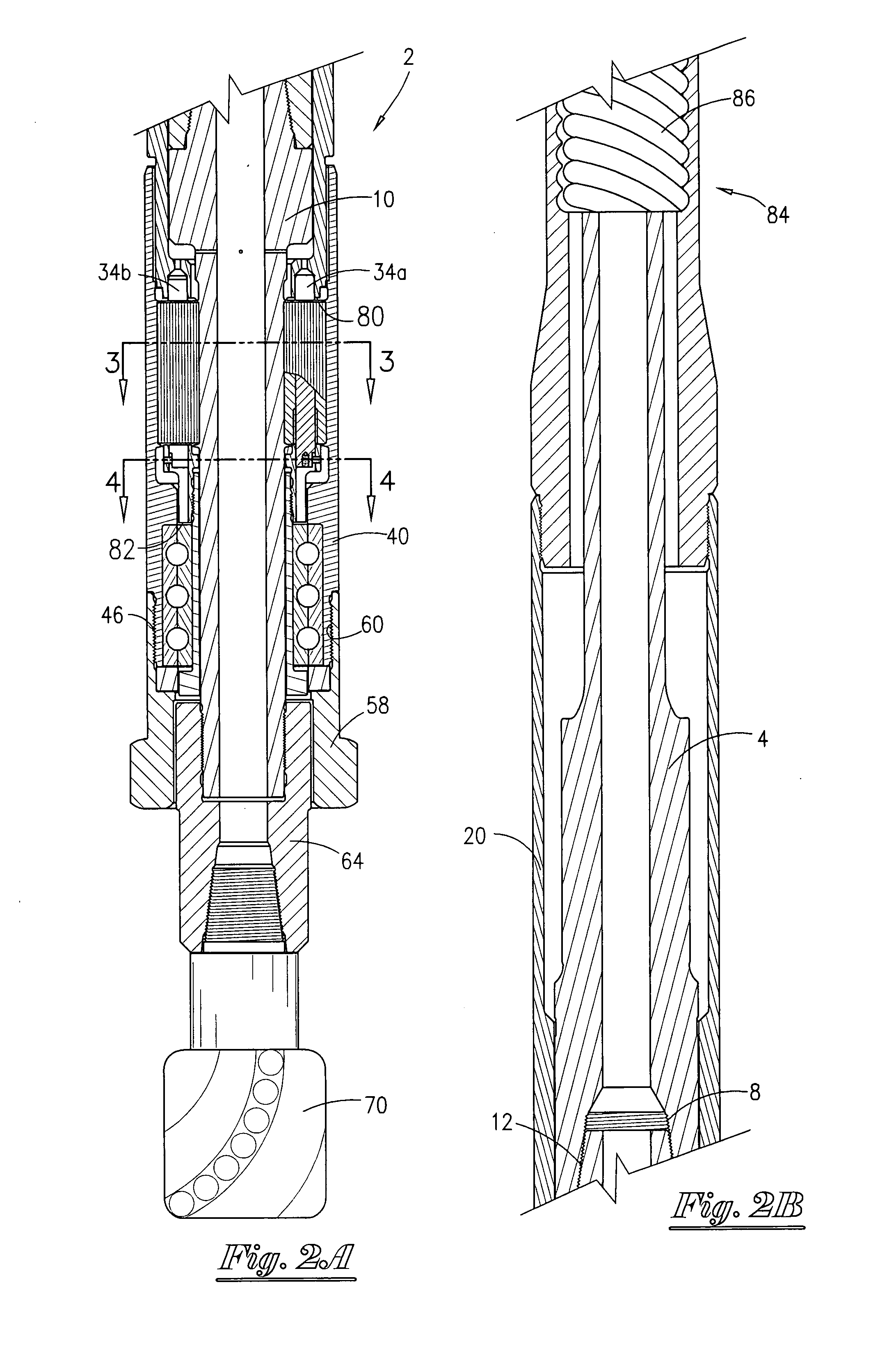

Drilling apparatus and system for drilling wells

Owner:SOUTHARD DRILLING TECH

Apparatus and method for treating impurities in air and materials

ActiveUS20100054989A1Maximize removalMinimize negative effectCombination devicesMechanical apparatusAtmospheric airSports equipment

Owner:BLUEZONE IP HLDG LLC

Processing process of honey

The invention discloses a processing process of honey. The process comprises the following steps: (1) performing acceptance inspection on original honey: inspecting the original honey manually and performing sampling inspection at the same time; (2) melting crystallized honey in a water bath: putting the crystallized honey in the water bath, adding clear water and heating the water with steam to atemperature of 40 DEG C to 55 DEG C; (3) performing heating and premixing: pumping the heated honey into a feeding tank; (4) performing coarse filtration through a raw material tank: pumping the honey in the feeding tank into the raw material tank and arranging a 60-mesh filter screen on the inner upper side of the raw material tank; (5) performing process inspection; (6) performing filtration through filters: pumping the mixed honey into filter No.1 and filter No.2 in sequence; (7) performing concentration and sterilization: pumping the twice filtered honey into a raw material transit tank and performing the concentration and sterilization; (8) performing fine filtration: putting the concentrated honey into filter No.3; (9) performing mixing in a finished-product tank: pumping the honeyfiltered through the filter No.3 into the finished-product tank and performing physical stirring for 1h; and (10) performing filling. According to the invention, the flavor of finished honey productscan be improved.

Owner:安徽泓顺源生物科技有限公司

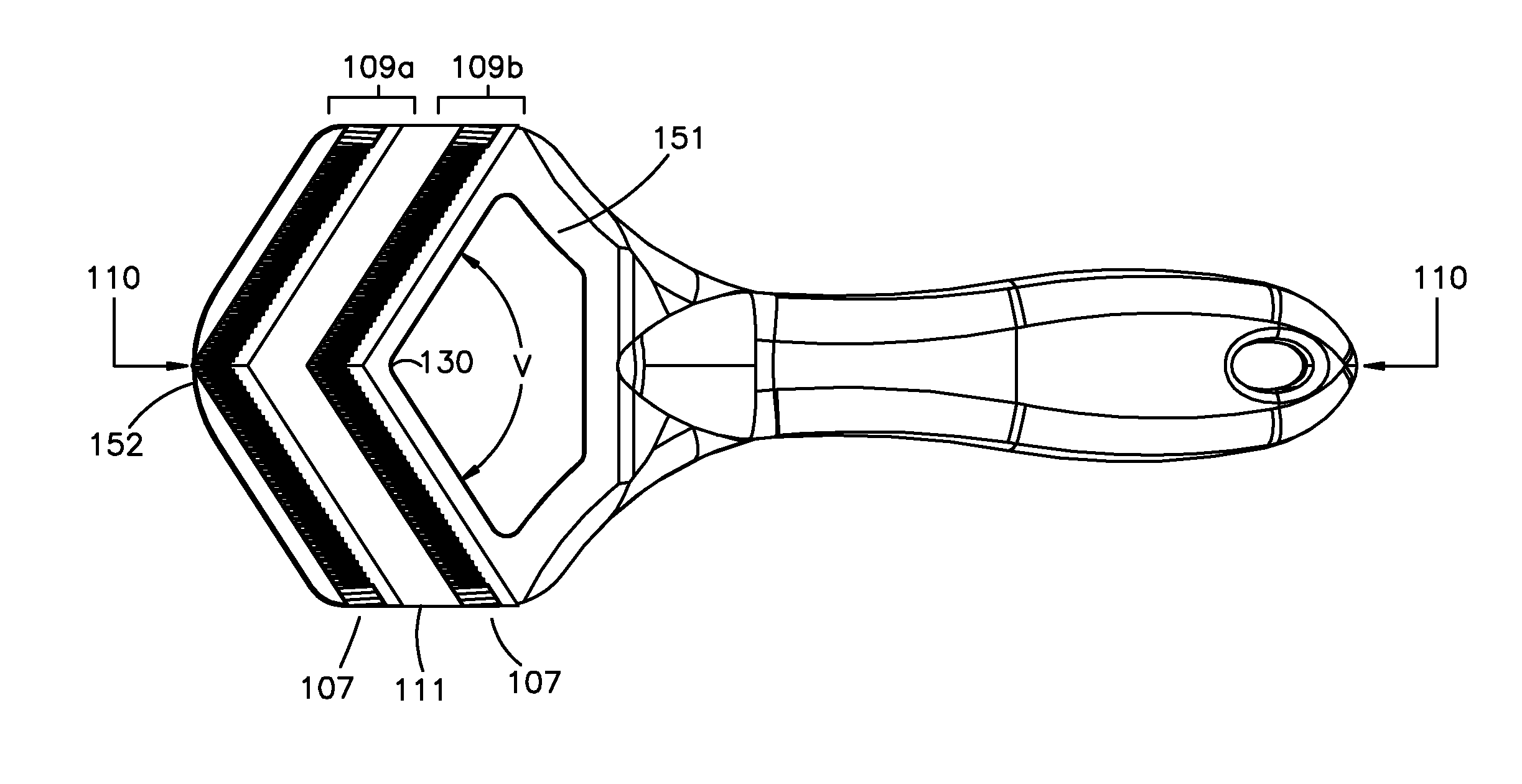

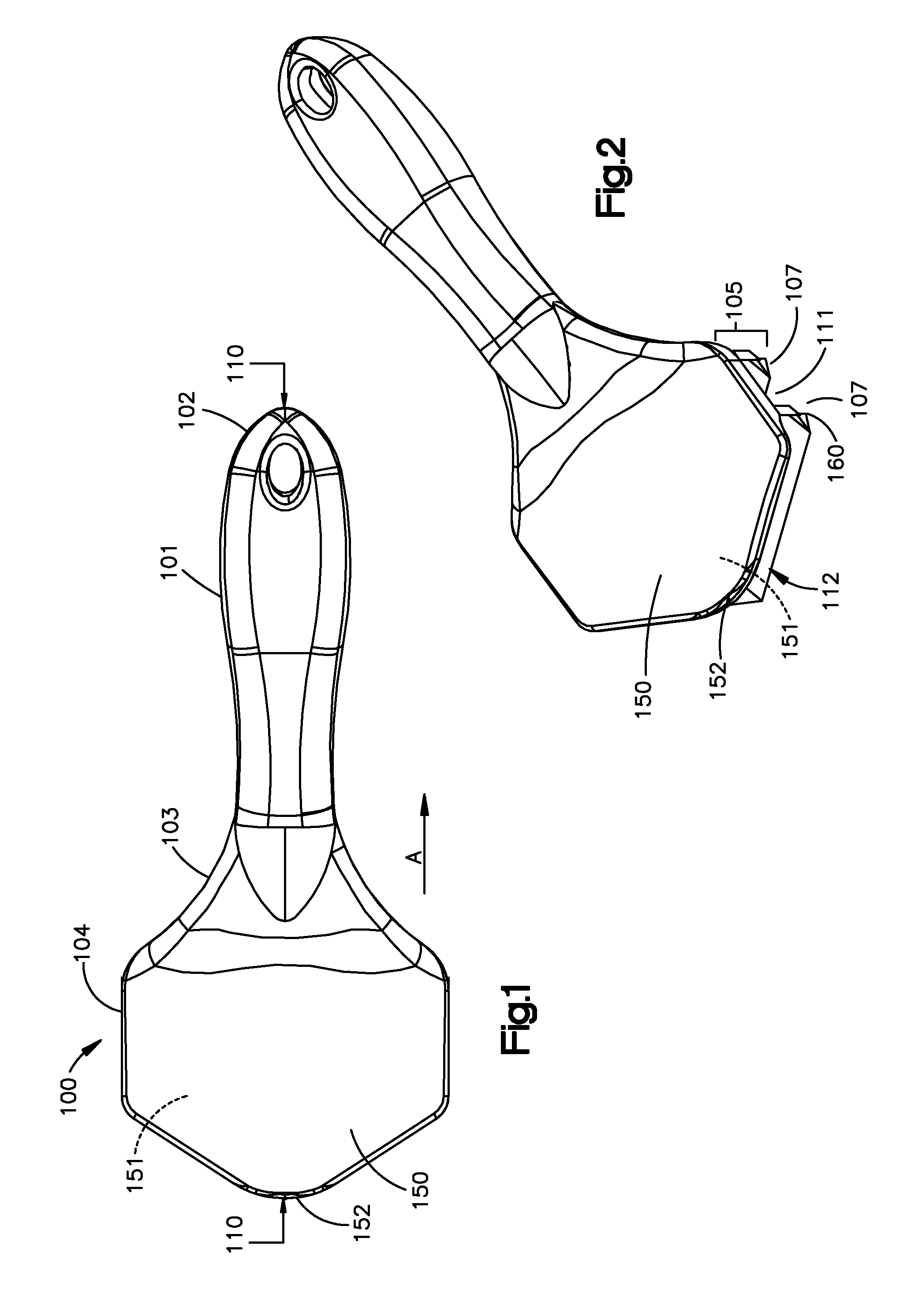

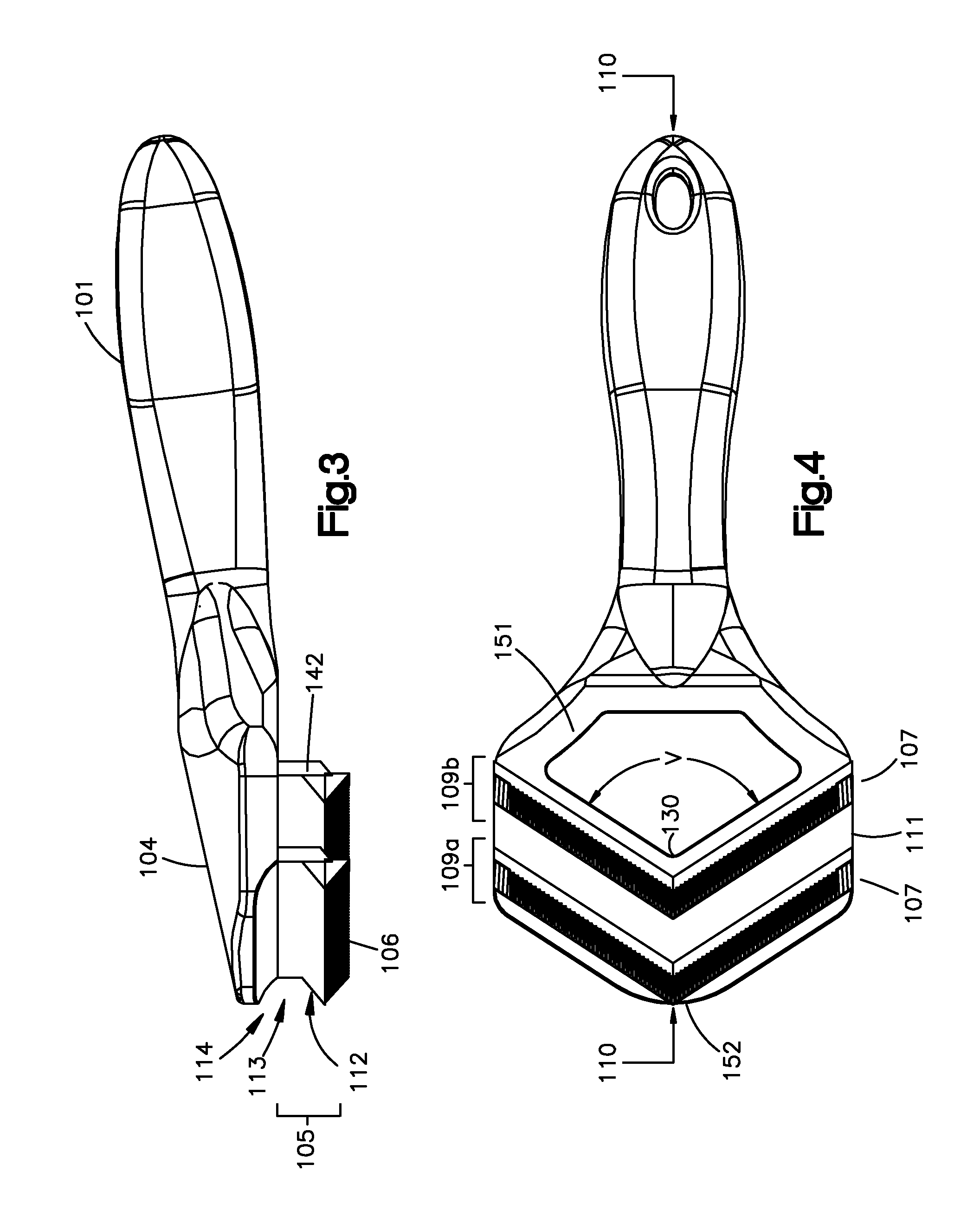

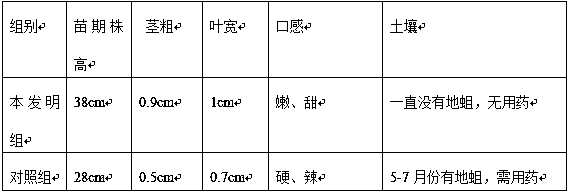

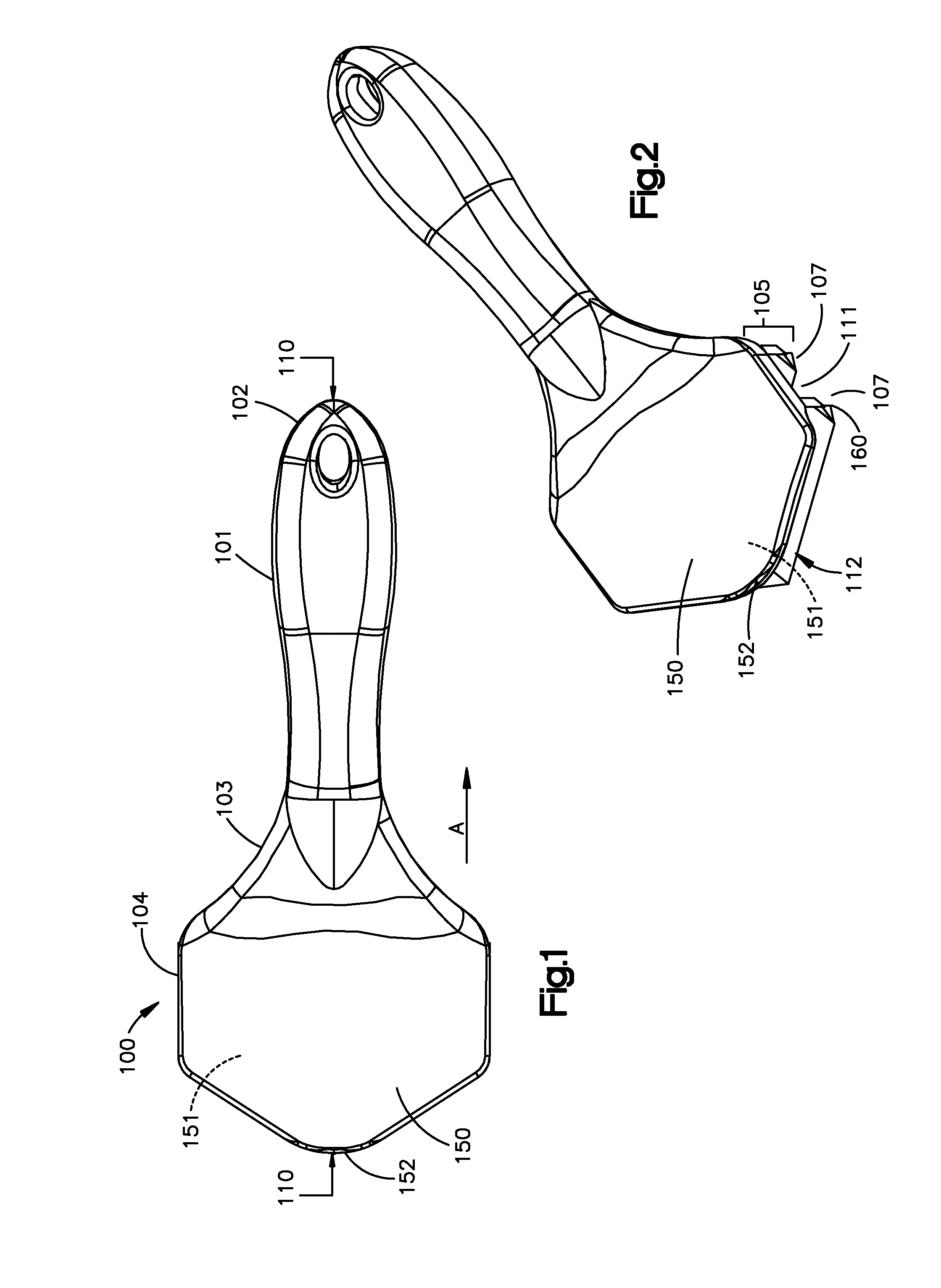

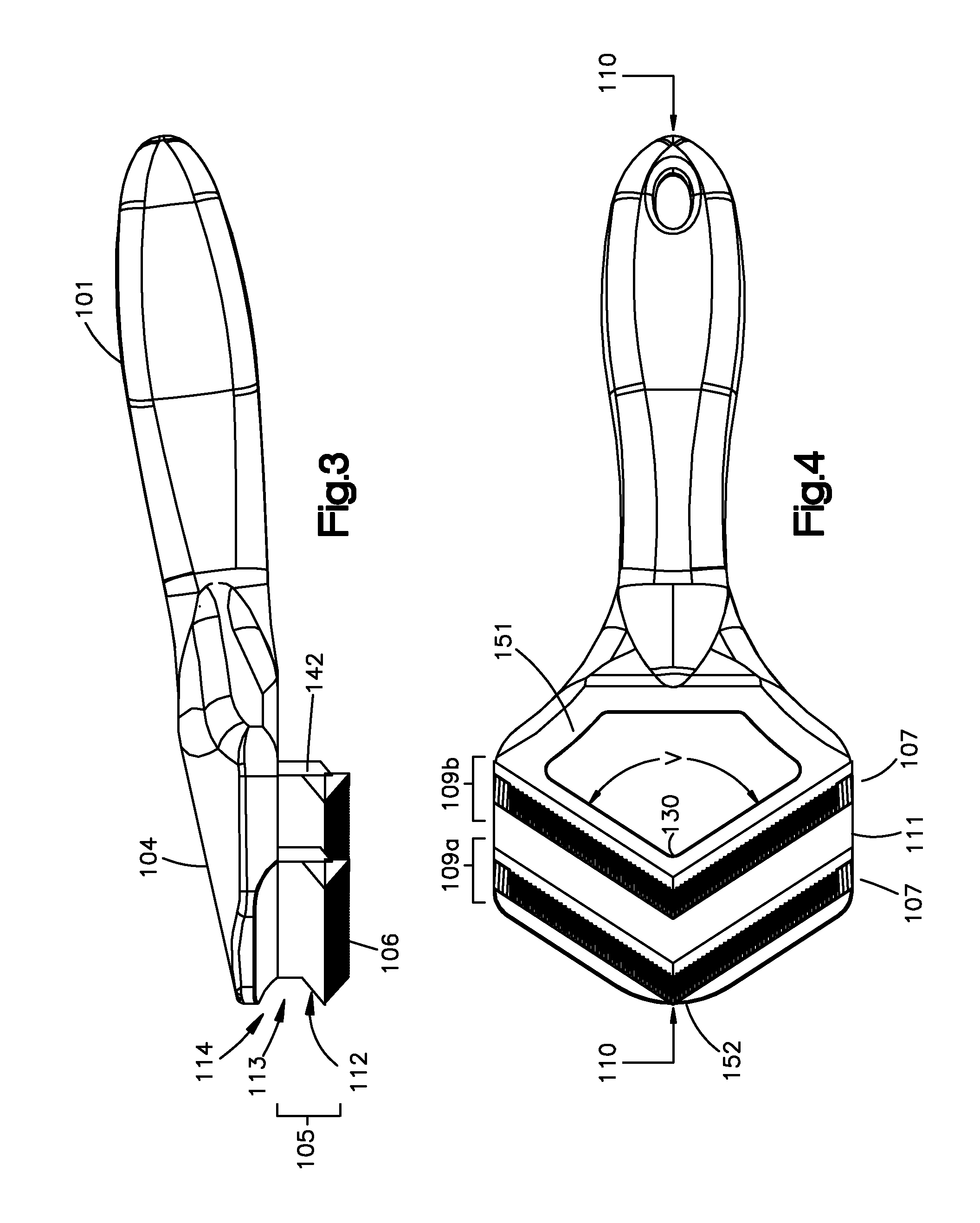

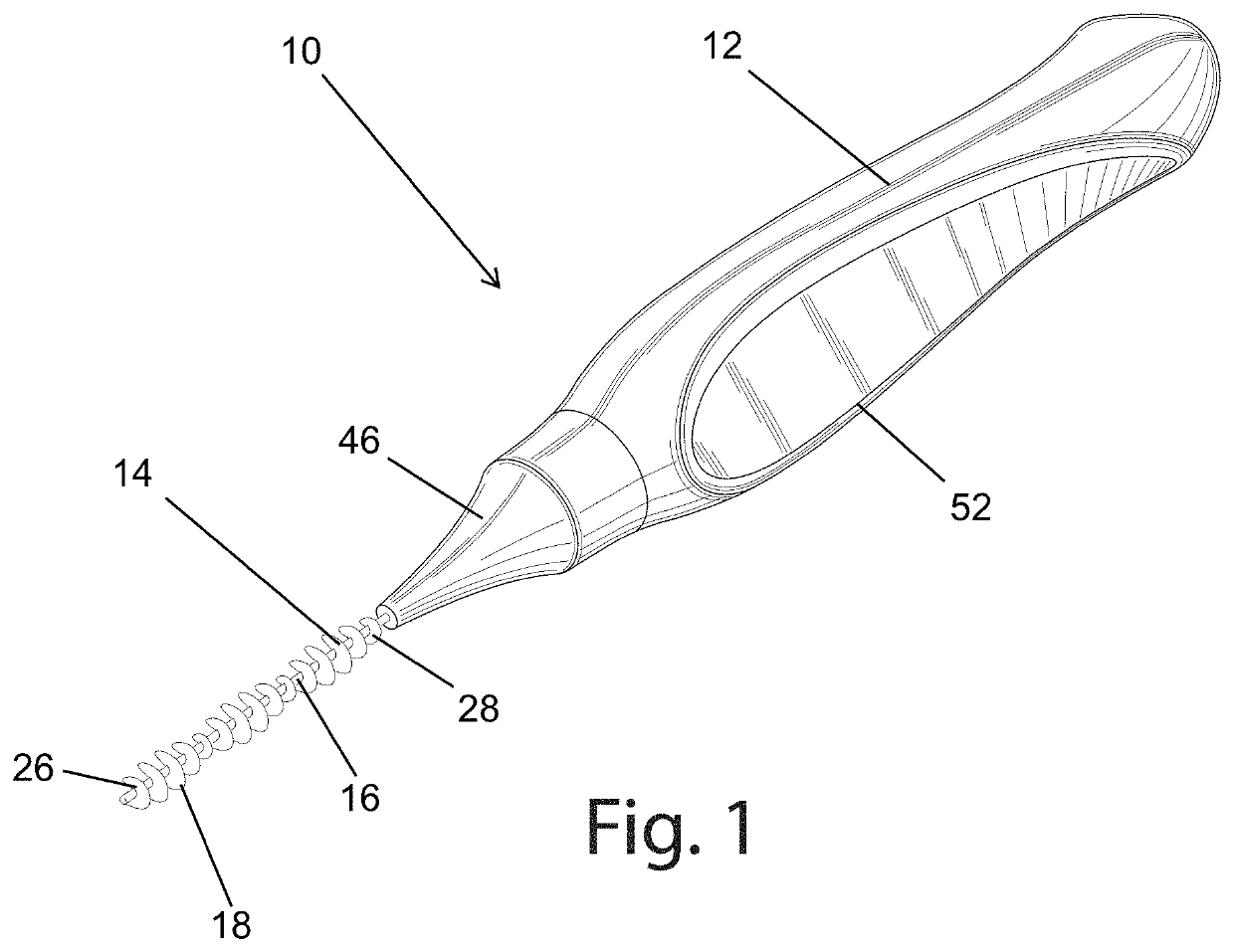

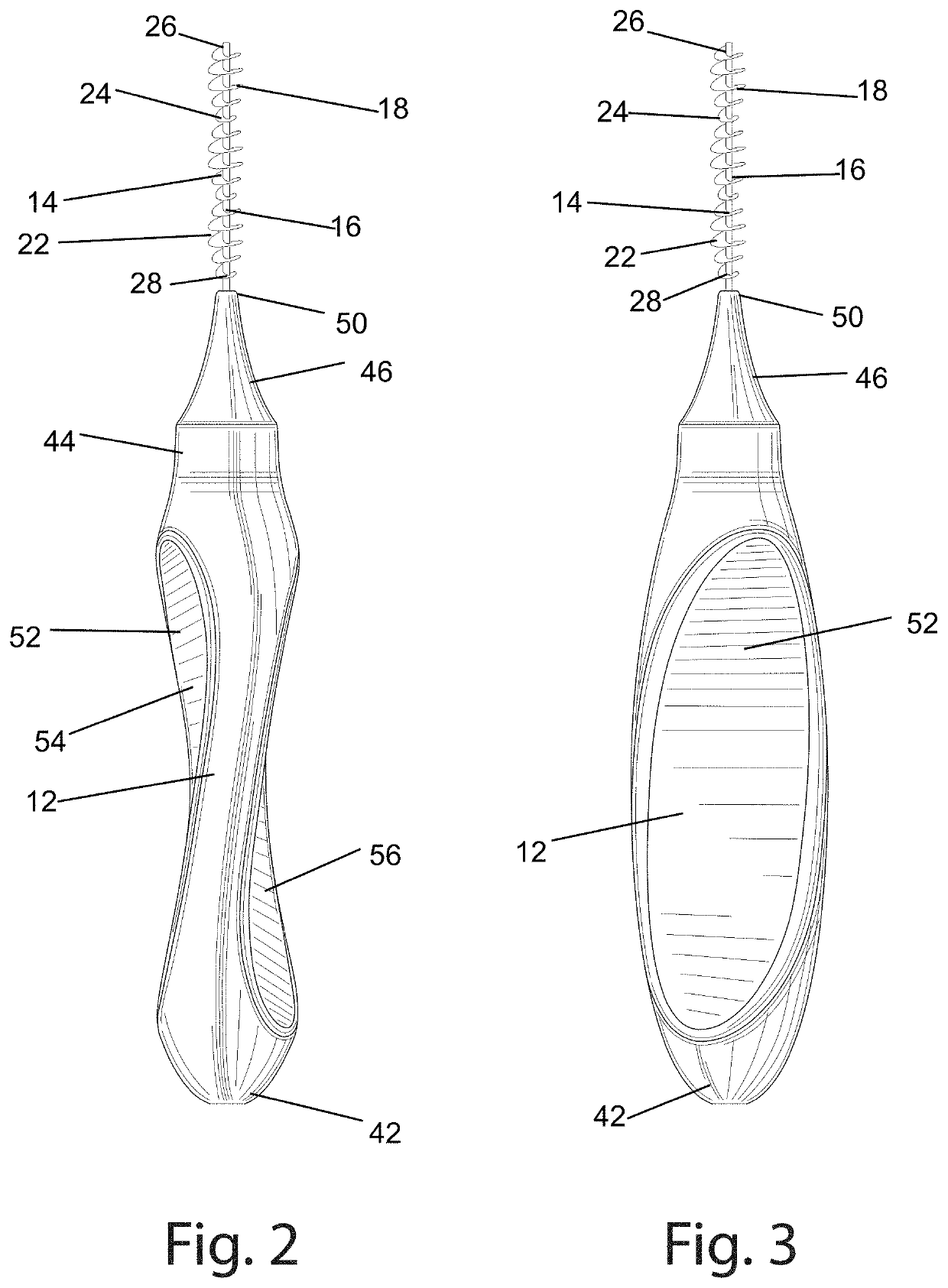

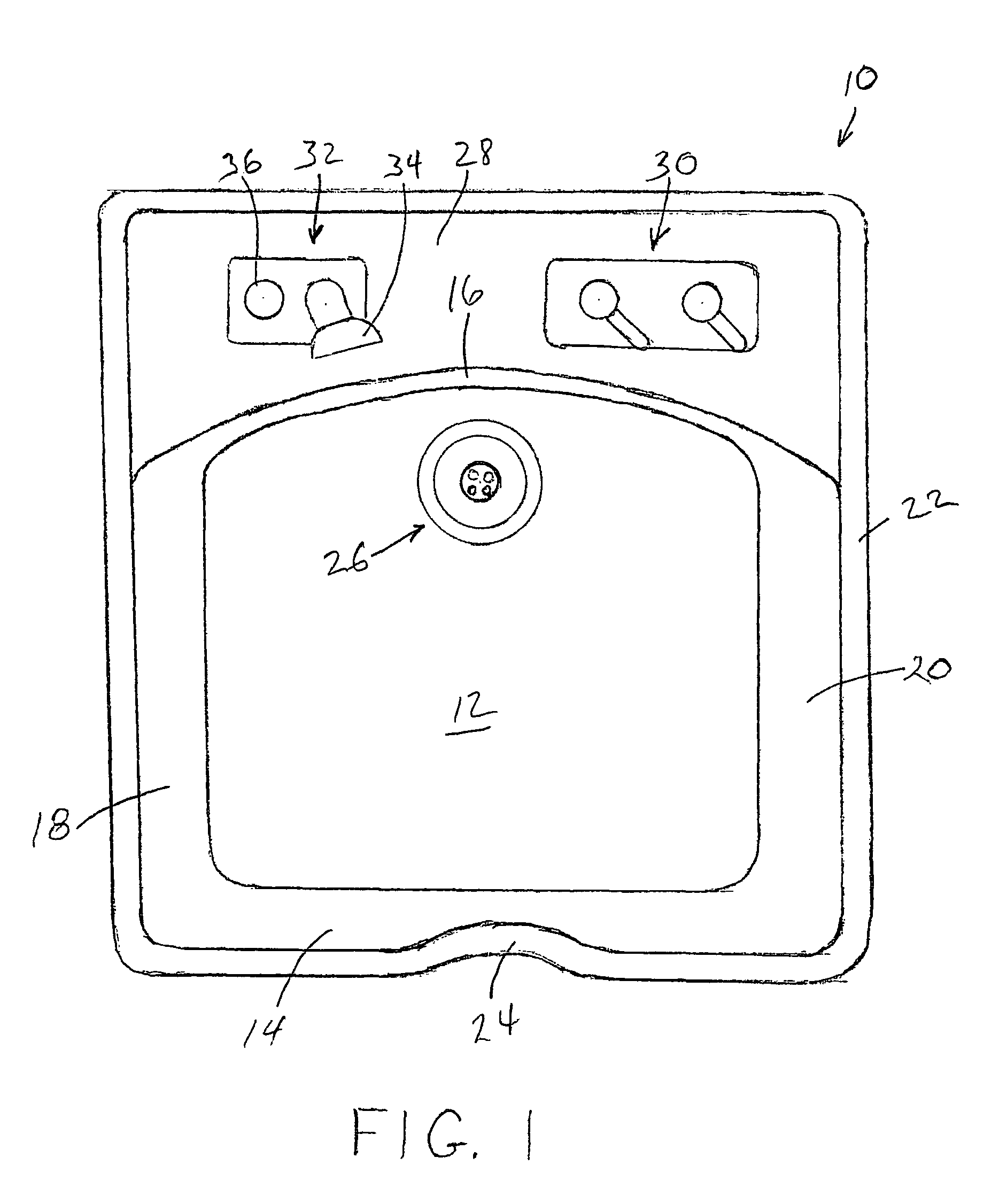

Pet grooming tool

An improved pet grooming tool is provided for grooming pets and removing loose or detached hair from their fur coats, while removing substantially no or acceptably little live hair and without the need to include any blade portion for engaging the loose or dead hairs. The tool can also collect the removed hair as opposed to permitting most of it to fall to the floor. In a preferred embodiment of the invention, the grooming tool includes an elongated handle portion having proximal and distal ends, a head portion at the distal end of the handle, and a carding portion on the head. A tool axis extends in a proximal direction from the head to the proximal end and in preferred embodiments of the invention, corresponds to the direction in which the tool is drawn across the animal's coat (the grooming direction). The grooming tool also has a plurality of tines, with a generally triangular shape when viewed from their sides or top, such that they narrow when extending from base to tip.

Owner:HARTZ MOUNTAIN

Method for producing spherical basic nickel carbonate by using ABS metallized material

ActiveCN106757116AEfficient separationLess impuritiesElectrolysis componentsSodium carbonateChemistry

The invention discloses a method for producing spherical basic nickel carbonate by using an ABS metallized material. The method comprises the following processing steps: plastic separation: crushing the ABS metallized material, putting the crushed ABS metallized material into a sulfuric acid solution of which the concentration in mass fraction is 20%, adding an oxidant, and stirring till ABS plastic is completely separated out; preparation of crude nickel sulfate: filtering a solution obtained after the above reaction, performing an electrodeposition reaction, and performing concentration to obtain a crude nickel sulfate crystal; preparation of fine nickel sulfate: mixing the crude nickel sulfate crystal with water and hydrogen peroxide, and performing filtration and extraction to obtain a fine nickel sulfate solution; and preparation of nickel carbonate: adding sodium carbonate into the fine nickel sulfate solution, adjusting the pH value to be 8, keeping the heating temperature and the stirring speed at 45 DEG C and 70 r / min correspondingly, continuing a reaction for 2.5 h, and then performing filtration, washing and drying to obtain spherical basic nickel carbonate. By adoption of the method disclosed by the invention, high-apparent-density spherical basic nickel carbonate can be recovered from the ABS metallized material; the recovery efficiency is high; and the purity of recovered spherical basic nickel carbonate is high.

Owner:怀化炯诚新材料科技有限公司

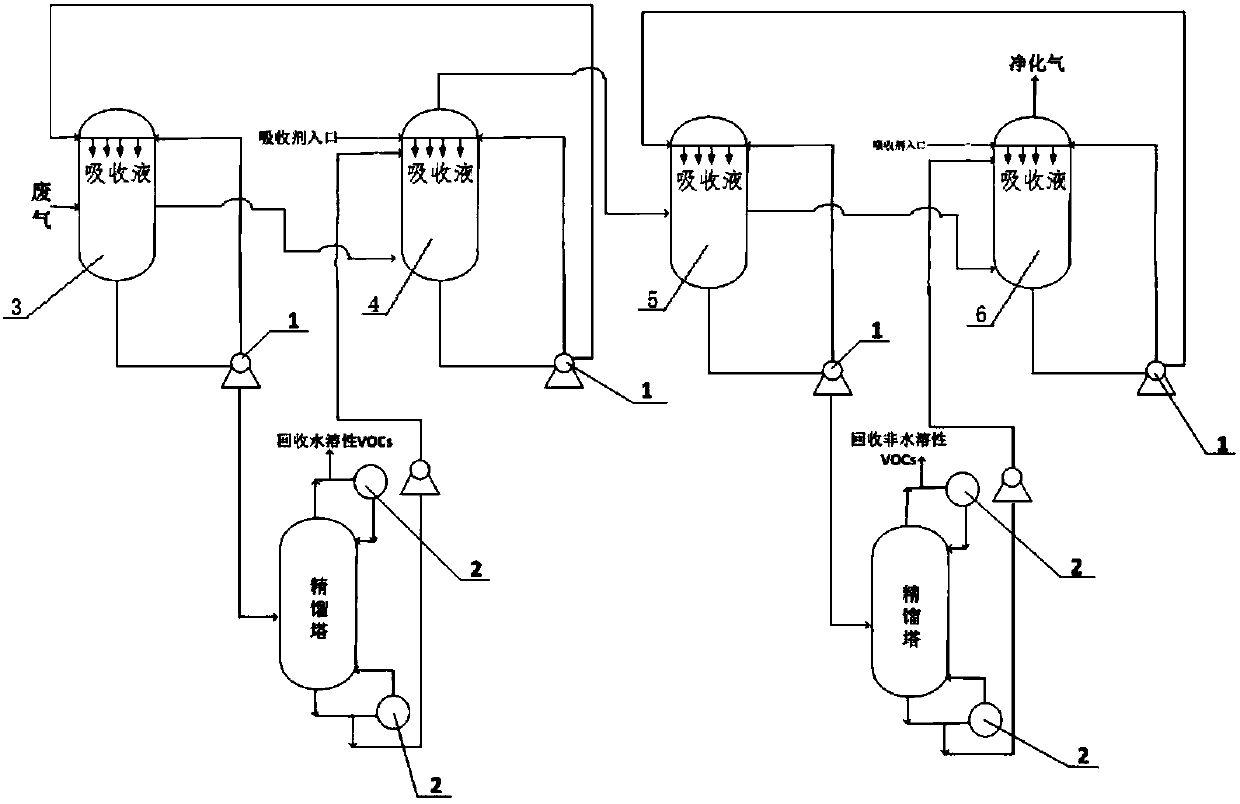

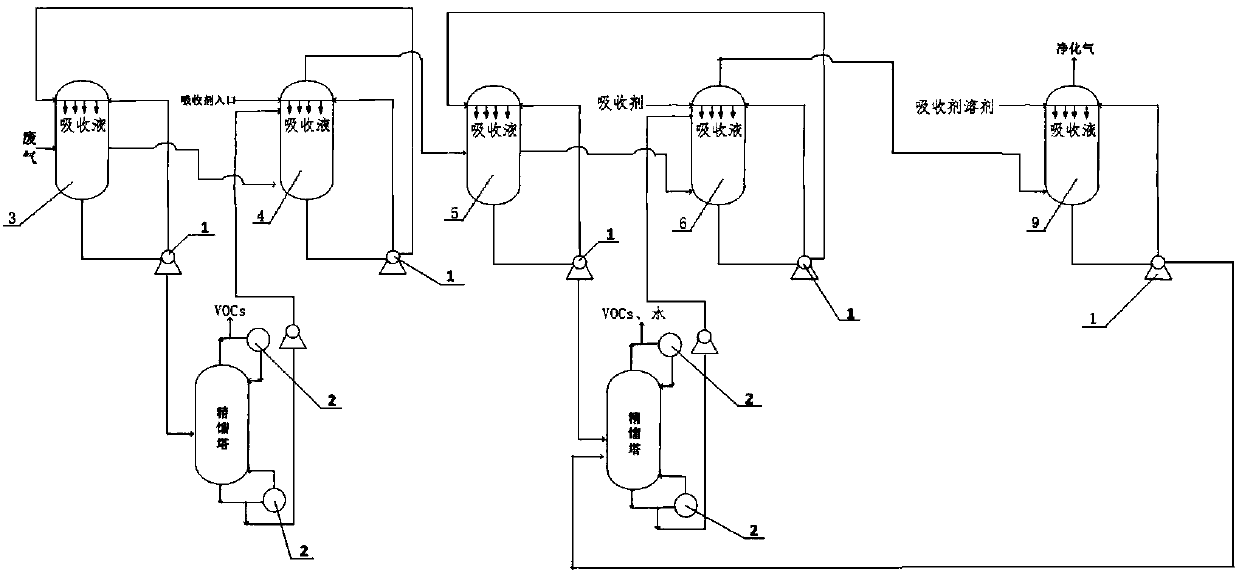

Treatment process of VOCs (volatile organic chemicals) waste gas

InactiveCN107774097AImprove purification efficiencyReduce exhaustGas treatmentDispersed particle separationWater insolubleEnvironmental engineering

The invention discloses a treatment process of VOCs (volatile organic chemicals) waste gas. The treatment process includes the steps: removing water-soluble VOCs; removing water-insoluble VOCs. Two steps adopt at least two serially connected waste gas absorption units. In the same removal step, absorbing agents enter from a tail end waste gas absorption unit, waste gas enters the waste gas absorption unit and contacts with the absorbing agents, one part of generated absorption liquid absorbing the VOCs cycles to the waste gas absorption unit and serves as the absorbing agents to be used, and the rest absorption liquid cycles to the front waste gas absorption unit and serves as absorbing agents of the front waste gas absorption unit to be used. The process has the advantages that the purification efficiency of the VOCs is improved, the consumption of the absorbing agents is reduced, energy consumption is reduced, and the height of an absorption tower is reduced.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

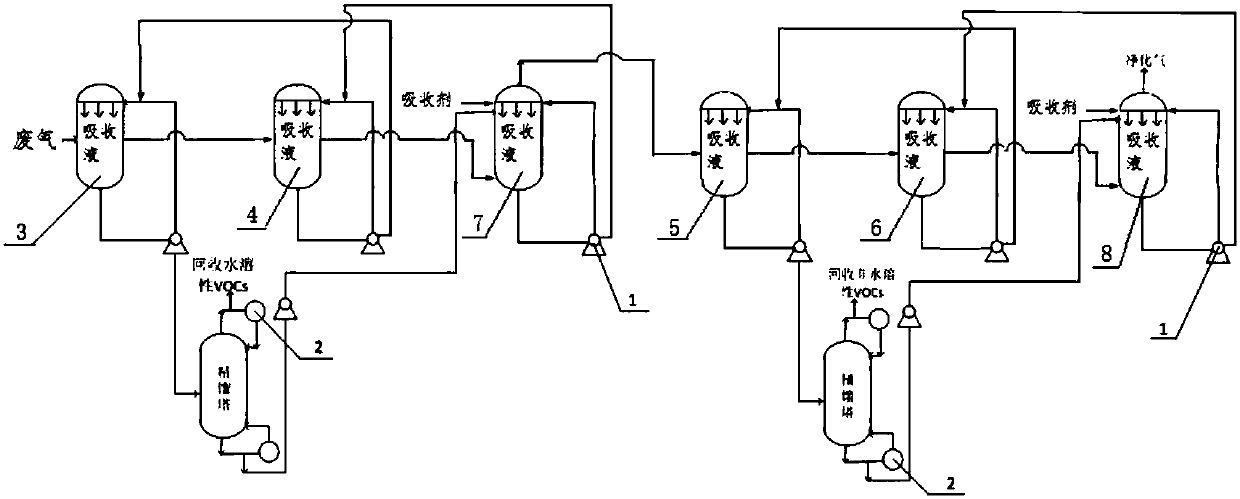

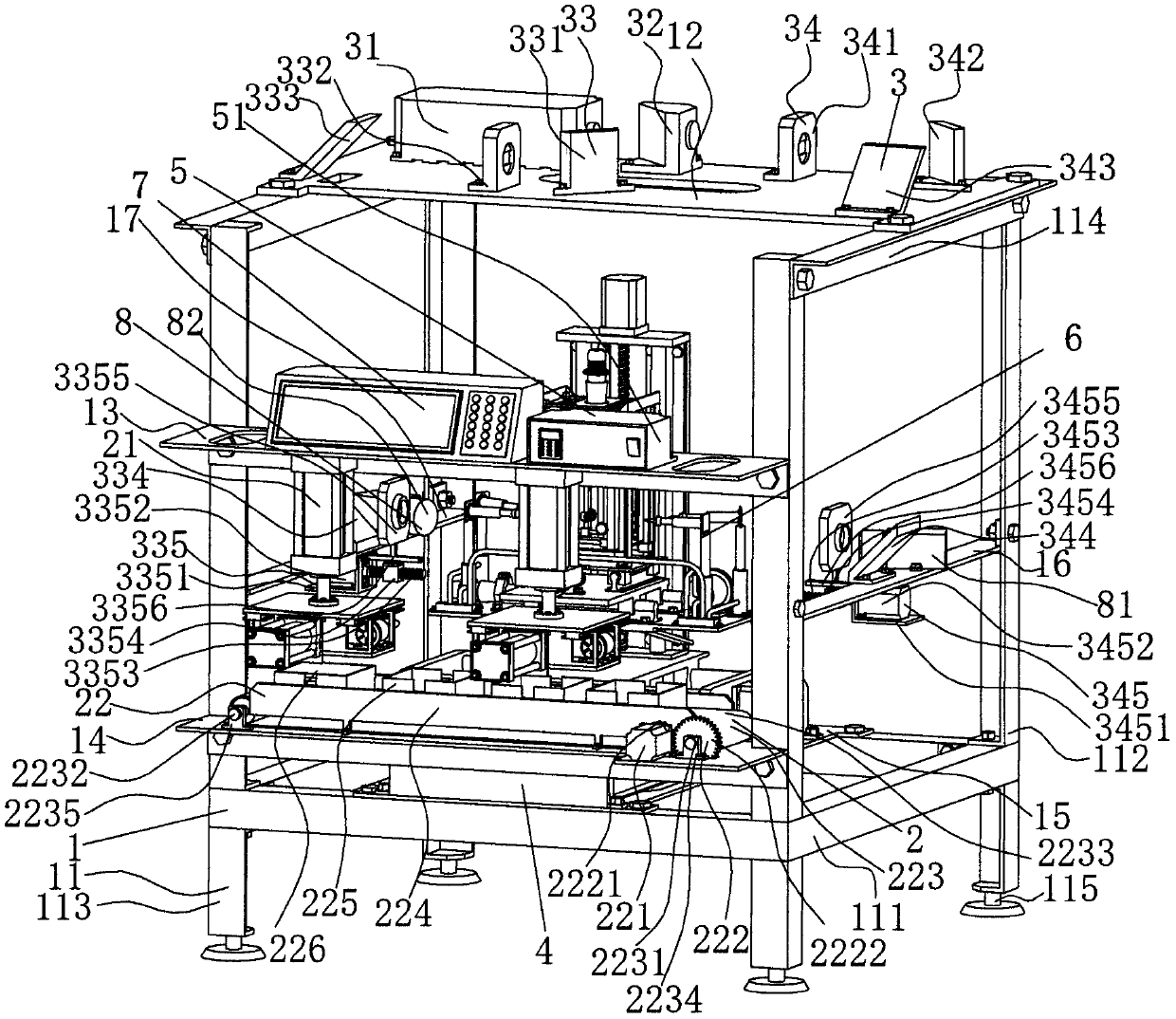

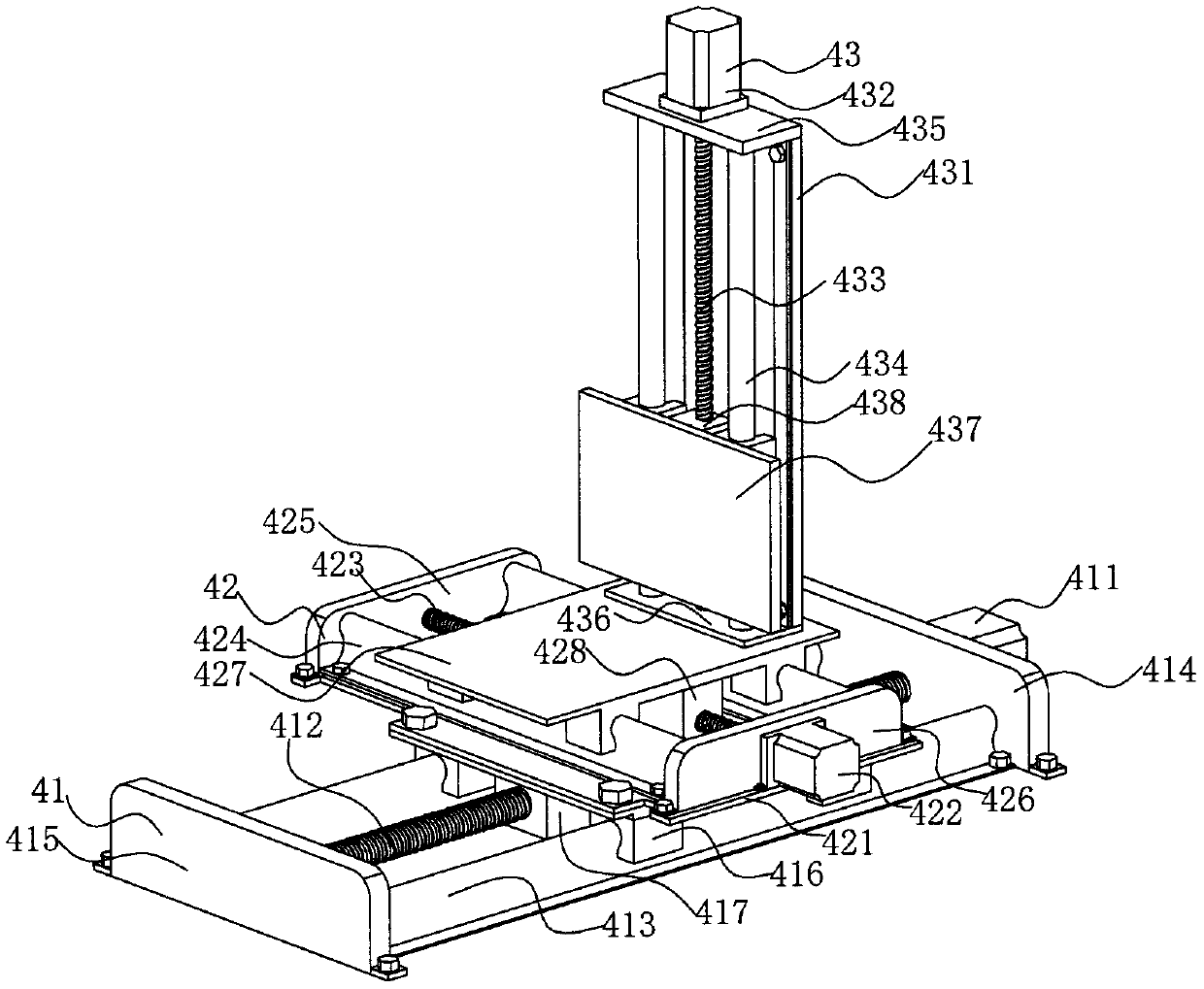

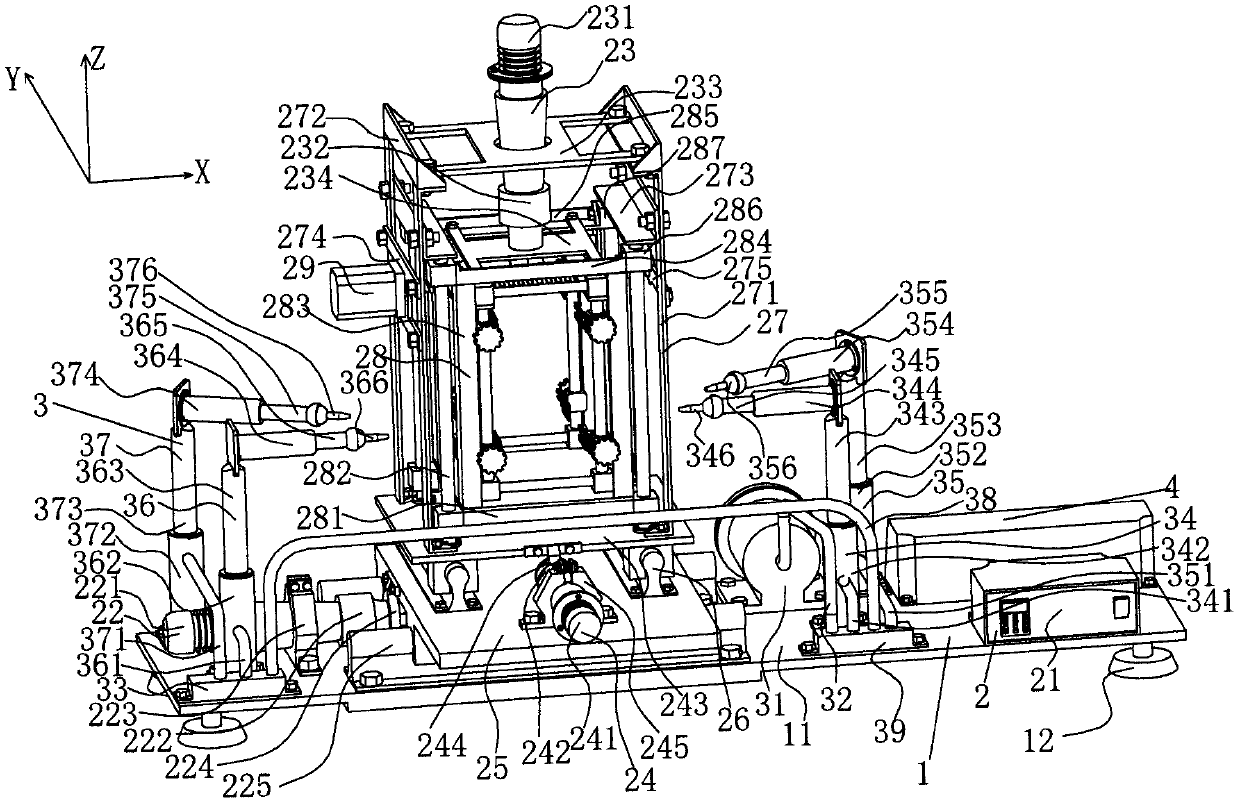

Efficient multi-freedom-degree ultrasonic vibration assisted double-sided laser machining device

ActiveCN110539074AMaximize removalImprove the quality of laser processingLaser beam welding apparatusMachining processOxide

The invention discloses an efficient multi-freedom-degree ultrasonic vibration assisted double-sided laser machining device which is composed of a machine frame, an automatic feeding and discharging device, a double-sided laser machining device body, a three-freedom-degree moving device, an ultrasonic vibration assisting device, an assisted air blowing device, a controller and a monitoring device.The automatic feeding and discharging device can automatically move workpieces to all working positions. The double-sided laser machining device body can machine the two sides of each workpiece at the same time, the taper of the machined workpieces is reduced, and the single-side laser machining can be conducted. The three-freedom-degree moving device can rapidly move the workpieces. The ultrasonic vibration assisting device can realize the three-freedom-degree vibration of the workpieces and reduce recast layers, oxides, micro cracks and other defects in the laser machining process. The assisted air blowing device can reduce the splashing of melt during machining through coaxial and paraxial air blowing. The efficient multi-freedom-degree ultrasonic vibration assisted double-sided lasermachining device has the advantages of being reliable in work, high in automation degree, diversified in function, convenient to maintain, high in work efficiency, high in workpiece machining quality,high in applicability and the like.

Owner:TIANJIN POLYTECHNIC UNIV

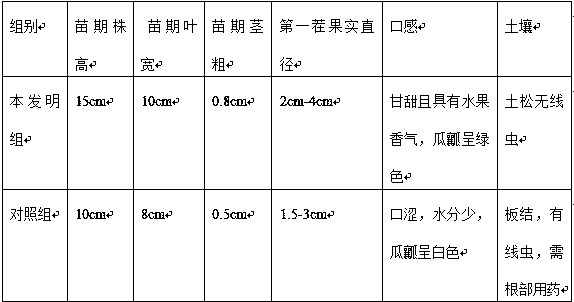

Efficient biogas slurry and fresh enzyme organic fertilizer and preparation technology thereof

InactiveCN110668867AReduce usageGrow fastNitrogenous fertilisersFertilizer mixturesMycotoxinInsect pest

The invention relates to an efficient biogas slurry and fresh enzyme organic fertilizer and a preparation technology thereof, and belongs to the technical field of efficient biogas slurry and fresh enzyme organic fertilizers. The efficient biogas slurry and fresh enzyme organic fertilizer comprises, by weight, 100 parts of biogas slurry, 0.1 part of original white spirit, 0.5-1 part of fruit enzyme, 0.25-0.5 kg of brown sugar and 0.02-0.1 part of a compound enzyme probiotic powder. The fertilizer is free of mycotoxin and other harmful bacteria, is rich in a large amount of amino acids, humic acid, vitamins and animal and plant proteins, can promote rapid growth of plants and resists diseases and insect pests, and can endow crops with fruit fragrance.

Owner:姜和利

Pet grooming tool

An improved pet grooming tool is provided for grooming pets and removing loose or detached hair from their fur coats, while removing substantially no or acceptably little live hair and without the need to include any blade portion for engaging the loose or dead hairs. The tool can also collect the removed hair as opposed to permitting most of it to fall to the floor. In a preferred embodiment of the invention, the grooming tool includes an elongated handle portion having proximal and distal ends, a head portion at the distal end of the handle, and a carding portion on the head. A tool axis extends in a proximal direction from the head to the proximal end and in preferred embodiments of the invention, corresponds to the direction in which the tool is drawn across the animal's coat (the grooming direction). The grooming tool also has a plurality of tines, with a generally triangular shape when viewed from their sides or top, such that they narrow when extending from base to tip.

Owner:HARTZ MOUNTAIN

Conditioning of biomass for improved c5/c6 sugar release prior to fermentation

InactiveUS20130014749A1Promote resultsSoftenBiofuelsFermentationLignocellulosic biomassCellulose breakdown

Disclosed is an improvement in a conventional process for C5 and C6 sugar recovery from lignocellulosic biomass for fermentation to ethanol, which process including the conventional steps of pretreatment of the biomass with steam at elevated temperature and pressure, collection of C5 sugars from hemicellulose breakdown, cellulose hydrolysis and collection of C6 sugars from cellulose breakdown. The improvement includes conditioning of the biomass prior to the pretreatment step by heating the biomass with steam for a time period between 5 minutes to 60 minutes to achieve a steam treated biomass having a temperature of about 80 to 100°C.; and adjusting a moisture content of the steam treated biomass to about 45% to 80%. An increased recovery of C5 and C6 sugars is achieved compared to the conventional process.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Biological nitrogen removal feed process

InactiveUS20140209536A1Promote denitrificationAccelerate denitrificationWater treatment parameter controlTreatment using aerobic processesNitrogen removalSludge

In a wastewater treatment system comprised of an anoxic tank outputting to a biological reactor and outputting from the reactor to a clear well, a process for controlling the rate and timing of flow through the reactor by means of a floating pump within the anoxic tank. Further enhancement of denitrification is achieved by sending internal recycles into the sludge zone of the anoxic tank via a baffle positioned within the sludge layer.

Owner:DOBIE KEITH +2

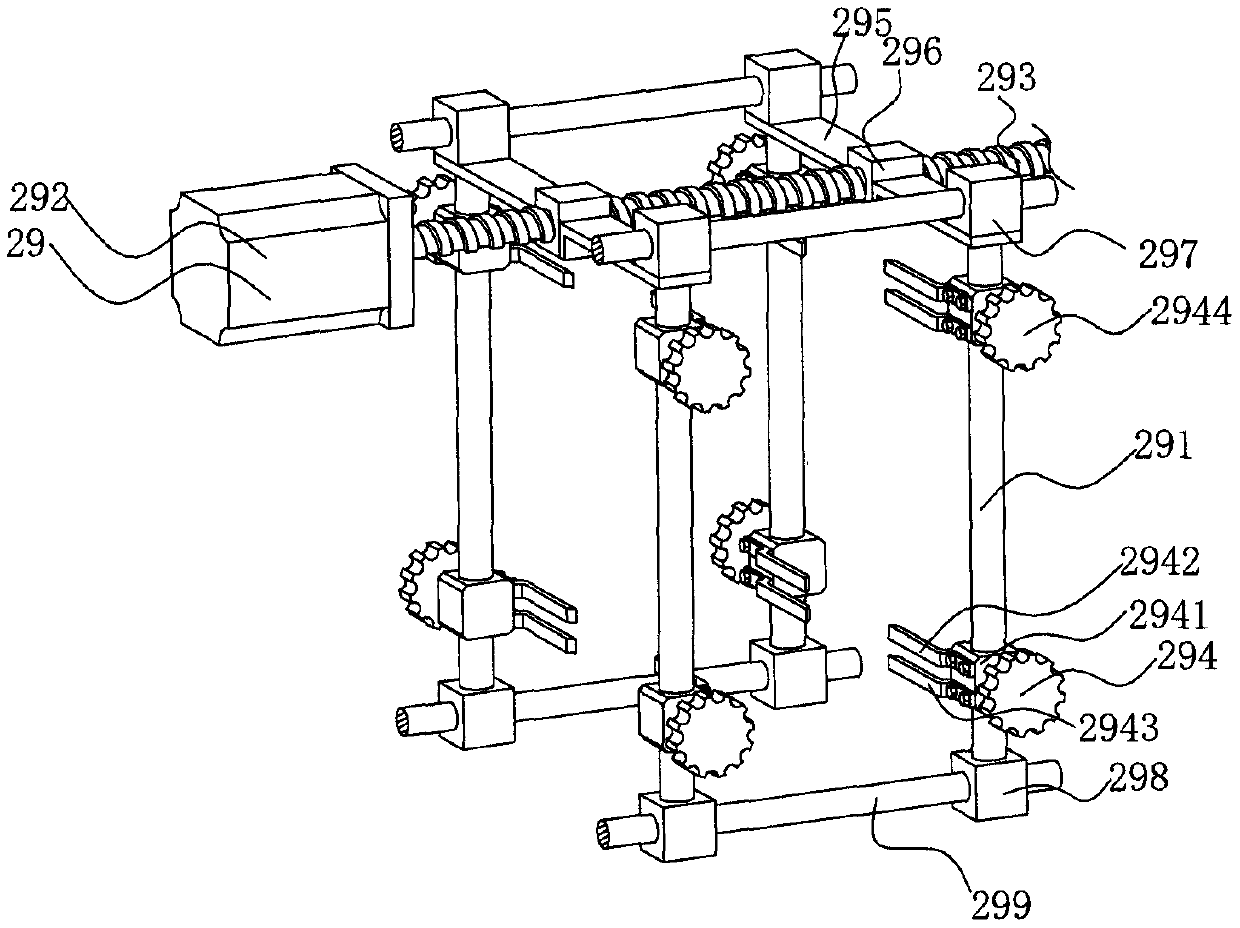

Semi-automatic auxiliary laser processing device

ActiveCN110539073AWork reliablyHigh degree of automationLaser beam welding apparatusMulti degree of freedomOxide

The invention discloses a semi-automatic auxiliary laser processing device which is composed of a machine frame, an ultrasonic vibration auxiliary device, an auxiliary air blowing device and a controller. The ultrasonic vibration auxiliary device can achieve multi-degree-of-freedom vibration of workpieces, defects such as a recasting layer, oxide and microcracks existing in the laser processing process can be greatly reduced, and workpiece processing efficiency can be improved. The auxiliary air blowing device adopts coaxial and paraxial air blowing, melt flashing during processing can be reduced, and workpiece processing quality is improved. The semi-automatic auxiliary laser processing device has the advantages of being reliable to work, high in automation degree, multifunctional, convenient and fast to maintain, high in processing efficiency, high in workpiece processing quality, high in applicability and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Production process of motor shells for vehicles

ActiveCN109609858AHigh yield strengthImprove the quality of useFurnace typesHeat treatment furnacesMachiningImpurity

The invention discloses a production process of motor shells for vehicles. Raw materials of the motor shells for the vehicles comprise the following components in percentage by mass: 0.2-0.5% of C, 1.5-2.6% of Al, 0.6-0.8% of Mn, 0.5-1.1% of Cu, 0.8-1.6% of Si, 0.2-0.4% of Mo, 0.7-1.9% of Ti, S not more than 0.02%, N not more than 0.02%, P not more than 0.02%, and the balance of Fe and inevitableimpurities; the production process of primary smelting, secondary smelting, ternary smelting, and then casting, heat treatment and machining is adopted to obtain the needed motor shells for the vehicles; and through the mode, the content of impurities in castings can be greatly reduced, the grain size of the castings is increased, the physical performance of the motor shells for the vehicles is finally realized, in particular, the yield strength is more prominent, and the use quality is improved.

Owner:博众优浦(常熟)汽车部件科技有限公司

Interdental toothbrush

An interdental brush has a handle with a helix style shape, as well as sections of long and short bristles to maximize plaque removal. The handle has a first end, a second end and a length between the first and second ends. The handle defines a longitudinal axis extending through the handle along the length. A brush extends from the handle and includes a stem projecting along the longitudinal axis and a set of bristles extending laterally outwardly from the stem. Each of the bristles has a bristle length from the stem to a bristle tip, the bristle tips collectively defining a bristle profile. In one embodiment, the bristle profile alternates along the stem between valley sections of short bristle length and mountain sections of long bristle length. The handle includes a grip portion along the length, and the grip portion is shaped such that it is twisted about the longitudinal axis in the manner of a helix.

Owner:RANIR LLC

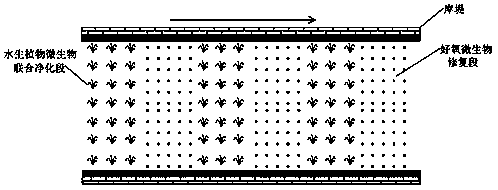

Method for repairing eutrophication water by utilizing aquatic plants and microorganisms together

PendingCN108821433AImprove purification effectMaximize removalTreatment with aerobic and anaerobic processesWater/sewage treatment apparatusForeign matterEutrophication

The invention provides a method for repairing eutrophication water by utilizing aquatic plants and microorganisms together. The method specifically comprises the following steps: a, river channel cleaning: removing various floating foreign matters on water surface through manual salvaging, and reserving volunteer plants of the water; b, aquatic plant-microorganism combined purification sections: adopting a stereoscopic structure of an aquatic plant floating bed, reasonably distributing in the water, and forming a zonal plant net wall having certain width and traversing a river channel; c, aerobic microorganism repairing sections: utilizing microbial flora, distributing in downstream water zones of the aquatic plant-microorganism combined purification sections after domestication, moderately aerating, and increasing the dissolved oxygen in the water of the river channel; d, sequentially distributing the aquatic plant-microorganism combined purification sections and the aerobic microorganism repairing sections along the river channel in a reciprocating and serial connection way, and forming a purification system of continuous batches. According to the method provided by the invention, the self cleaning capacity of the water can be improved while the water quality is purified to the maximum, the effect of beautifying the water is also integrated, secondary pollution cannot be generated, and the characteristics of environment protection, energy conservation and reclamation are integrated.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Treatment process of VOCs exhaust gas

InactiveCN107670465AReduce exhaustImprove purification efficiencyGas treatmentDispersed particle separationExhaust fumesWater soluble

The invention discloses a treatment process of VOCs exhaust gas. The treatment process comprises the steps of water-soluble VOCs removal, non-water-soluble VOCs removal and exhaust gas treatment. In the removal steps, at least two serially connected exhaust gas absorbing units are adopted, an absorbent enters the tail end exhaust gas absorbing unit in the same removal step, the exhaust gas entersthe exhaust gas absorbing units and is in contact with the absorbent, then a part of produced absorption liquid absorbing VOCs is circulated back to the exhaust gas absorbing units to serve as the absorbent, and the rest is circulated back to the previous exhaust gas absorbing unit to serve as the absorbent of the previous exhaust gas absorbing unit. The process has the advantages of improving theVOCs purifying efficiency, decreasing the use amount of the absorbent, reducing energy consumption and reducing the height of an absorption tower. In addition, absorbent in exhaust gas is recycled byadopting the process, and the use amount of the absorbent is decreased to the greatest degree.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

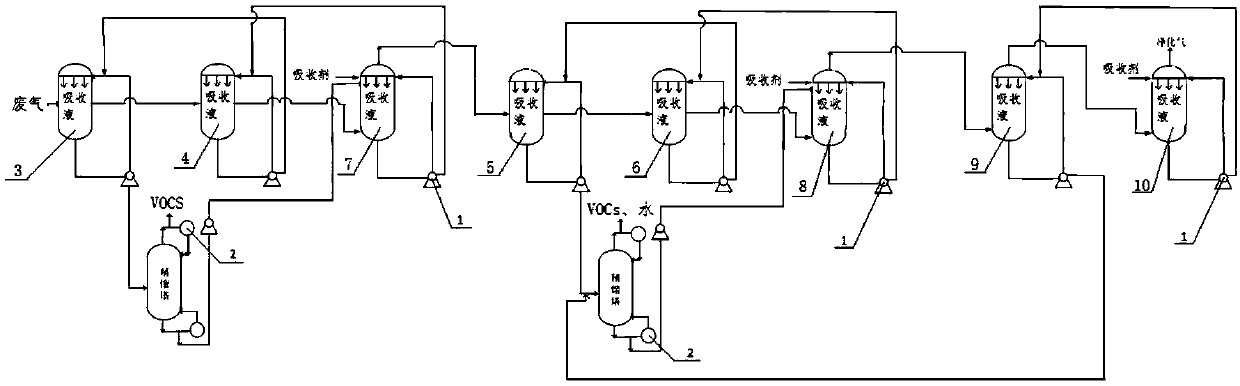

Purification method of ganirelix acetate

ActiveCN102993274BHigh yieldHigh purityLuteinising hormone-releasing hormonePeptide preparation methodsGanirelixPurification methods

The invention provides a purification method of ganirelix acetate. The purification method comprises the steps of (1) purification of ganirelix crude peptide, wherein octadecylsilane bonded silica is adopted as a fixed phase, perchlorate / phosphoric acid solution with certain concentration is taken as an A phase and acetonitrile is taken as a B phase, the ganirelix crude peptide is purified by a gradient-elution high performance liquid chromatography (HPLC) method; (2) salt conversion and purification, wherein the alkylsilane bonded silica is taken as the fixed phase, glacial acetic acid solution with a certain concentration is taken as the A phase and the acetonitrile is taken as the B phase, salt conversion and purification are carried out by adopting the gradient elution HPLC method, and the solution collected and subjected to freeze-drying to obtain the ganirelix acetate. The invention aims at providing the purification method of the ganirelix acetate with stable and controllable process, high yield, high purity, and wide practical value and application prospect.

Owner:HYBIO PHARMA

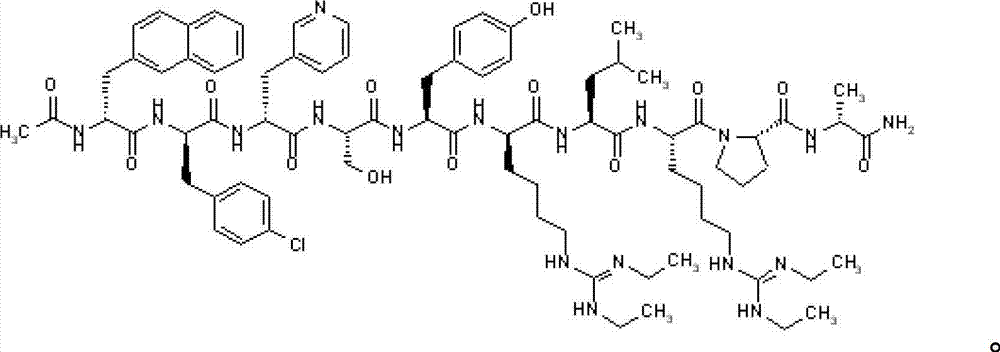

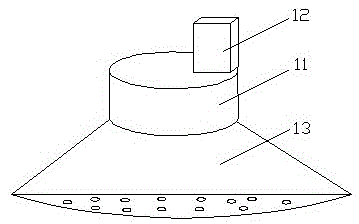

Compound dust collector for boilers

ActiveCN104984617AGood dust removal and purification effectAvoid pollutionCombination devicesFlue gasEvaporation

The invention discloses a compound dust collector for boilers. The compound dust collector comprises an electrostatic deduster connected to the flue of a boiler, and also comprises a shaft well electric field, an alkali solution tank, a sprayer and an evaporation drying box, the shaft well electric field is formed by a shaft well, a conductive rod, an electrode positioned in the shaft well and a high-voltage electrostatic power supply positioned outside the shaft well, the positive electrode of the high-voltage electrostatic power supply is connected with the outer wall of the shaft well through a lead, the negative electrode of the power supply is connected with the electrode through the conductive rod, the alkali solution tank is positioned outside the shaft well, the sprayer is arranged in the shaft well, the sprayer is arranged above the electrode, the sprayer is connected with the alkali solution tank through a solution spraying tube, the evaporation drying box is connected with the bottom of the shaft well, and the top of the shaft well is connected with the electrostatic deduster. The compound dust collector can maximally remove ash particles in flue gas, reduce haze in air and remove sulfur dioxide in the flue gas, also can effectively prevent secondary water pollution caused by ash and water mixture, and realizes a good flue gas dedusting and purifying effect.

Owner:HMEI THREAD CO LTD OF YINBIN SICHUAN

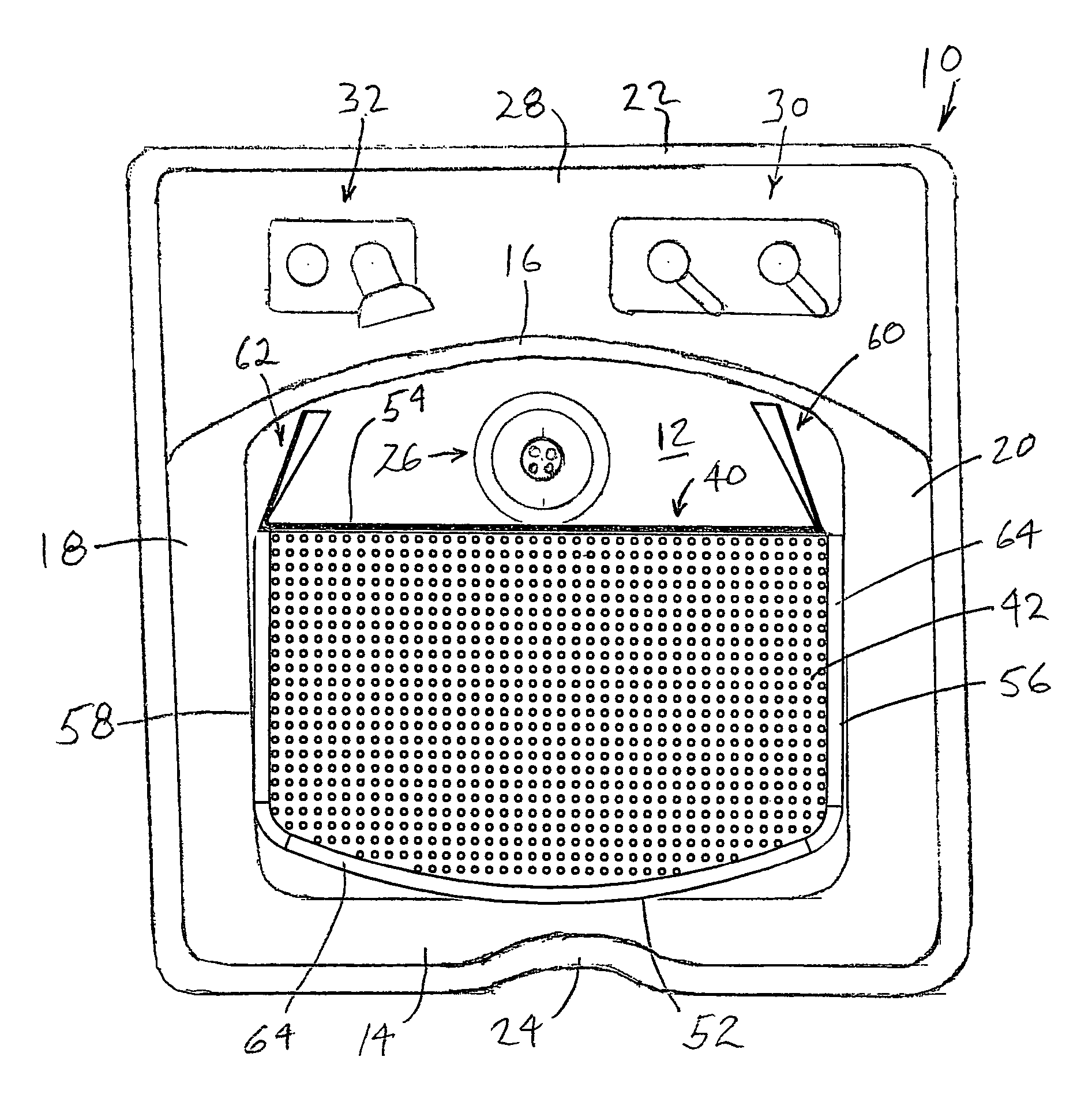

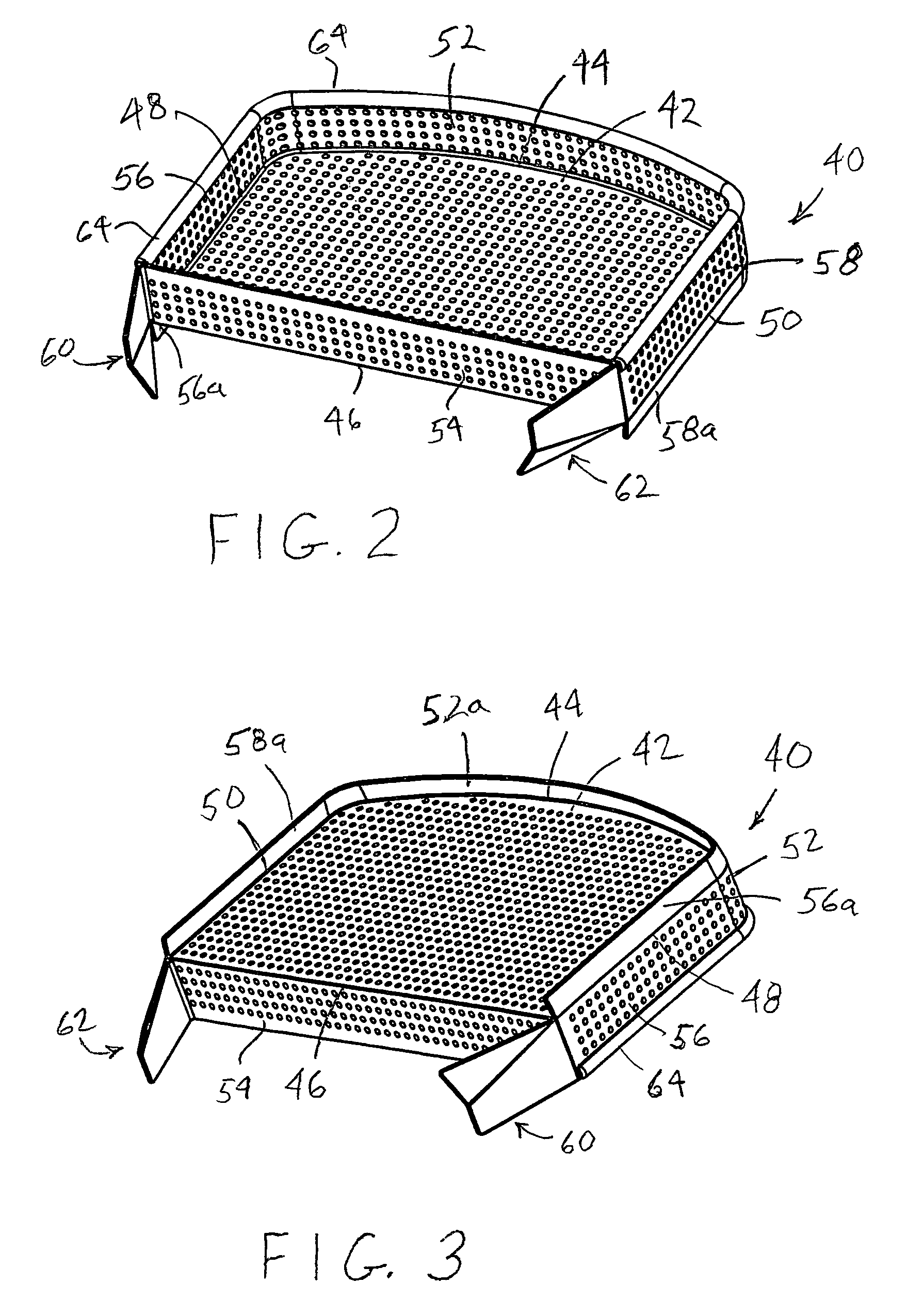

Drainage tray for shampooing bowls

InactiveUS8032957B2Maximize removalEasy accessPackaging toiletriesPackaging cosmeticsEngineeringFront and back ends

A drainage tray is adapted to be placed in a hair shampooing bowl having a bottom and front and rear walls extending upwardly from the bottom, a drain opening adjacent the front wall, and a peripheral edge spaced above the bottom and including an area on the front wall for supporting the neck of a person. The tray, when supported on the bottom of a shampooing bowl, is spaced below the peripheral edge and includes a perforated bottom wall having a front end, a rear end and sides between the front and rear ends and a perforated peripheral side wall extending upwardly from the bottom wall about the front and rear ends and the sides thereof. A portion of the peripheral side wall extends below the bottom wall to support the bottom wall of the tray above the bottom of a shampooing bowl.

Owner:SULLIVAN KATHLEEN M

A production process of motor housing for automobile

ActiveCN109609858BHigh yield strengthImprove the quality of useFurnace typesHeat treatment furnacesElectric machineryUltimate tensile strength

The invention discloses a production process of motor shells for vehicles. Raw materials of the motor shells for the vehicles comprise the following components in percentage by mass: 0.2-0.5% of C, 1.5-2.6% of Al, 0.6-0.8% of Mn, 0.5-1.1% of Cu, 0.8-1.6% of Si, 0.2-0.4% of Mo, 0.7-1.9% of Ti, S not more than 0.02%, N not more than 0.02%, P not more than 0.02%, and the balance of Fe and inevitableimpurities; the production process of primary smelting, secondary smelting, ternary smelting, and then casting, heat treatment and machining is adopted to obtain the needed motor shells for the vehicles; and through the mode, the content of impurities in castings can be greatly reduced, the grain size of the castings is increased, the physical performance of the motor shells for the vehicles is finally realized, in particular, the yield strength is more prominent, and the use quality is improved.

Owner:博众优浦(常熟)汽车部件科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com