Compound dust collector for boilers

A dust removal device and composite technology, which is applied in the direction of combined devices, dispersed particle separation, chemical instruments and methods, etc., can solve problems such as difficult to achieve dust removal and purification effects, secondary water pollution, and impact on environmental quality, and achieve good flue gas dust removal Purification effect, prevention of secondary water pollution, effect of reducing smog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

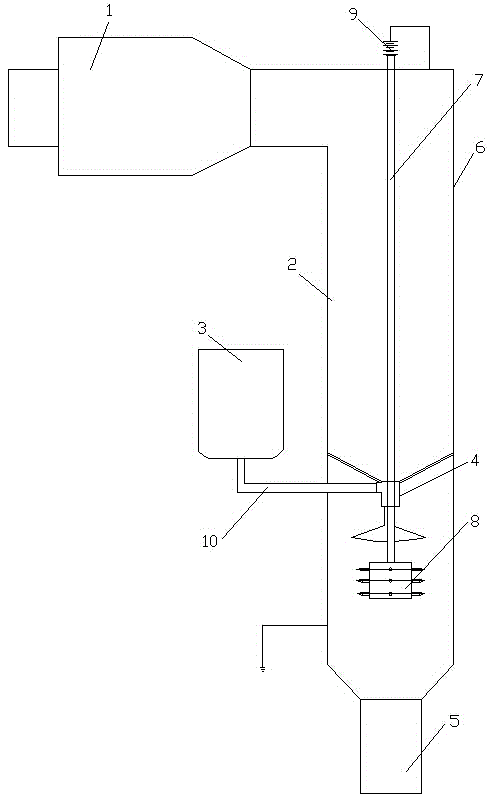

[0036] see figure 1, a composite dedusting device for a boiler, including an electrostatic precipitator 1 connected to the boiler flue, and also includes a shaft electric field 2, an alkali tank 3, a sprayer 4 and an evaporation drying box 5, and the shaft electric field 2 is composed of a shaft 6. The conductive rod 7, the electrode 8 located in the shaft 6 and the high-voltage electrostatic power supply 9 outside the shaft 6 are formed. The positive pole of the high-voltage electrostatic power supply 9 is connected to the outer wall of the shaft 6 through a wire, and the negative pole is connected to the electrode 8 through the conductive rod 7. The lye tank 3 is located outside the shaft 6, the sprayer 4 is located in the shaft 6, the sprayer 4 is arranged above the electrode 8, the sprayer 4 is connected with the lye tank 3 through the liquid spray pipe 10, and the evaporation drying box 5 is connected to the shaft The bottom of shaft 6 is connected, and the top of vertica...

Embodiment 2

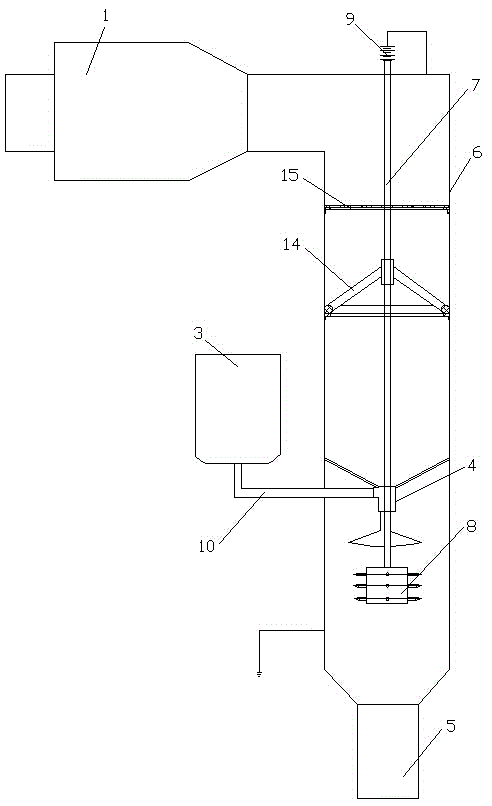

[0039] see figure 1 and figure 2 , a composite dedusting device for a boiler, including an electrostatic precipitator 1 connected to the boiler flue, and also includes a shaft electric field 2, an alkali tank 3, a sprayer 4 and an evaporation drying box 5, and the shaft electric field 2 is composed of a shaft 6. The conductive rod 7, the electrode 8 located in the shaft 6 and the high-voltage electrostatic power supply 9 outside the shaft 6 are formed. The positive pole of the high-voltage electrostatic power supply 9 is connected to the outer wall of the shaft 6 through a wire, and the negative pole is connected to the electrode 8 through the conductive rod 7. The lye tank 3 is located outside the shaft 6, the sprayer 4 is located in the shaft 6, the sprayer 4 is arranged above the electrode 8, the sprayer 4 is connected with the lye tank 3 through the liquid spray pipe 10, and the evaporation drying box 5 is connected to the shaft The bottom of shaft 6 is connected, and th...

Embodiment 3

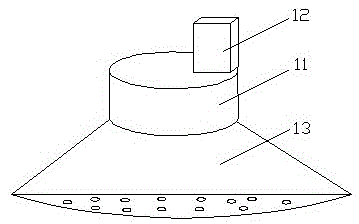

[0043] Reference figure 2 and image 3 , a composite dedusting device for a boiler, including an electrostatic precipitator 1 connected to the boiler flue, and also includes a shaft electric field 2, an alkali tank 3, a sprayer 4 and an evaporation drying box 5, and the shaft electric field 2 is composed of a shaft 6. The conductive rod 7, the electrode 8 located in the shaft 6 and the high-voltage electrostatic power supply 9 outside the shaft 6 are formed. The positive pole of the high-voltage electrostatic power supply 9 is connected to the outer wall of the shaft 6 through a wire, and the negative pole is connected to the electrode 8 through the conductive rod 7. The lye tank 3 is located outside the shaft 6, the sprayer 4 is located in the shaft 6, the sprayer 4 is arranged above the electrode 8, the sprayer 4 is connected with the lye tank 3 through the liquid spray pipe 10, and the evaporation drying box 5 is connected to the shaft The bottom of shaft 6 is connected, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com