A biomass bundling fuel combustion test bench

A biomass and experimental platform technology, applied in the direction of material thermal development, instruments, measuring devices, etc., can solve the problems of less equipment, insufficient accuracy, and in-depth research on the combustion characteristics of biomass bundling fuel, etc., to reduce errors , Reduce emissions, good dust removal and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

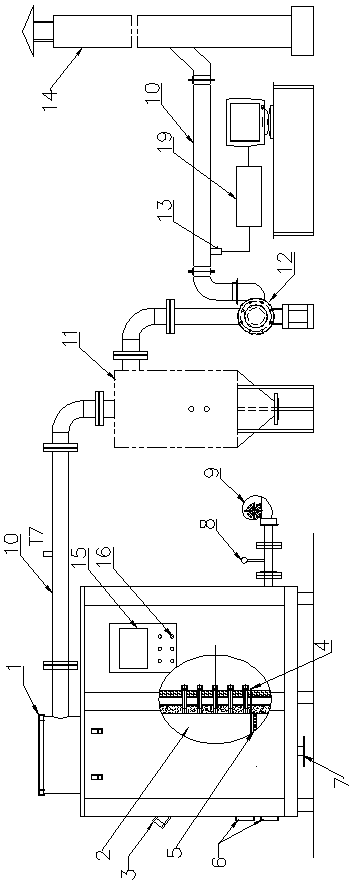

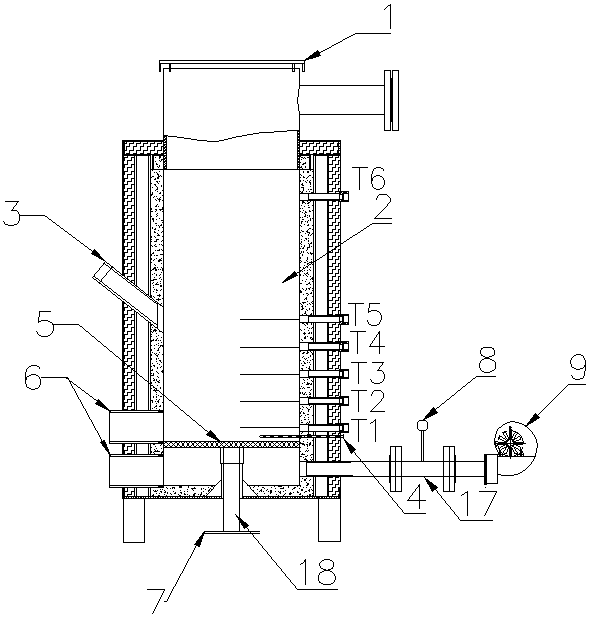

[0029] Such as figure 1 and figure 2 As shown, a biomass bundling fuel combustion test bench of the present invention includes a combustion device, a weighing system, a temperature measurement system and a flue gas composition measurement system. The combustion device includes a combustion chamber 2, which is a vertically arranged cylindrical structure. The inner lining of the combustion chamber 2 is made of high-temperature refractory concrete, and its outer cladding is made of aluminum silicate cutting board insulation material. The top of the combustion chamber 2 is provided with a feed port 1 , and the side of the combustion chamber 2 is provided with an observation window 3 . The bottom of the combustion chamber 2 is provided with a fire grate 5, and the combustion chamber 2 is provided with a soot cleaning port 6 at the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com